Introdução

Investing in a commercial keg washer can significantly enhance the efficiency and effectiveness of your brewery operations. Whether you’re a small craft brewery or a large-scale production facility, the benefits of automated keg washing systems are numerous and impactful. This blog explores why commercial keg washers are essential, their advantages, and considerations for choosing the right one for your brewery.

Eficiência e economia de tempo

One of the primary advantages of a commercial keg washer is its ability to streamline the cleaning process. Manual cleaning can be labor-intensive and time-consuming. A commercial keg washer automates this task, allowing your brewery to clean multiple kegs simultaneously with minimal supervision. This efficiency not only saves time but also reduces labor costs and ensures consistent cleaning quality.

Improved Cleaning Quality

Consistency in cleaning is crucial to maintaining the quality and taste of your brews. Commercial keg washers are designed to provide thorough and effective cleaning, removing residue and contaminants that can affect beer quality. Automated systems can reach inaccessible areas inside kegs, ensuring sanitation standards are met according to industry regulations.

Economia de custos

While the initial investment in a commercial keg washer may seem significant, it offers long-term cost savings. By reducing labor hours spent on manual cleaning and minimizing the risk of keg contamination, breweries can improve overall operational efficiency and reduce waste. The longevity of kegs can also be extended through proper cleaning, reducing replacement costs over time.

Sustainability and Environmental Impact

Automated keg washers typically use less water and cleaning chemicals compared to manual methods, contributing to sustainability efforts. By optimizing water and chemical usage, breweries can minimize their environmental footprint while meeting regulatory requirements. This aspect appeals not only to environmentally conscious consumers but also supports corporate social responsibility initiatives.

Enhanced Brewery Safety

Manual keg cleaning poses safety risks to brewery staff due to handling chemicals and heavy kegs. Commercial keg washers mitigate these risks by automating the cleaning process and reducing direct contact with hazardous substances. This improves workplace safety conditions and reduces the likelihood of accidents or injuries.

Escalabilidade e Flexibilidade

As your brewery grows, so do your production demands. Commercial keg washers offer scalability, allowing breweries to increase keg cleaning capacity as needed. Modular designs and customizable features enable flexibility in operation, accommodating different keg sizes and cleaning specifications without compromising efficiency or quality.

Considerações sobre manutenção

Like any equipment, commercial keg washers require regular maintenance to ensure optimal performance and longevity. Routine inspections, cleaning of filters and nozzles, and timely replacement of parts are essential. Choosing a supplier that offers reliable support and maintenance services can minimize downtime and maximize operational uptime.

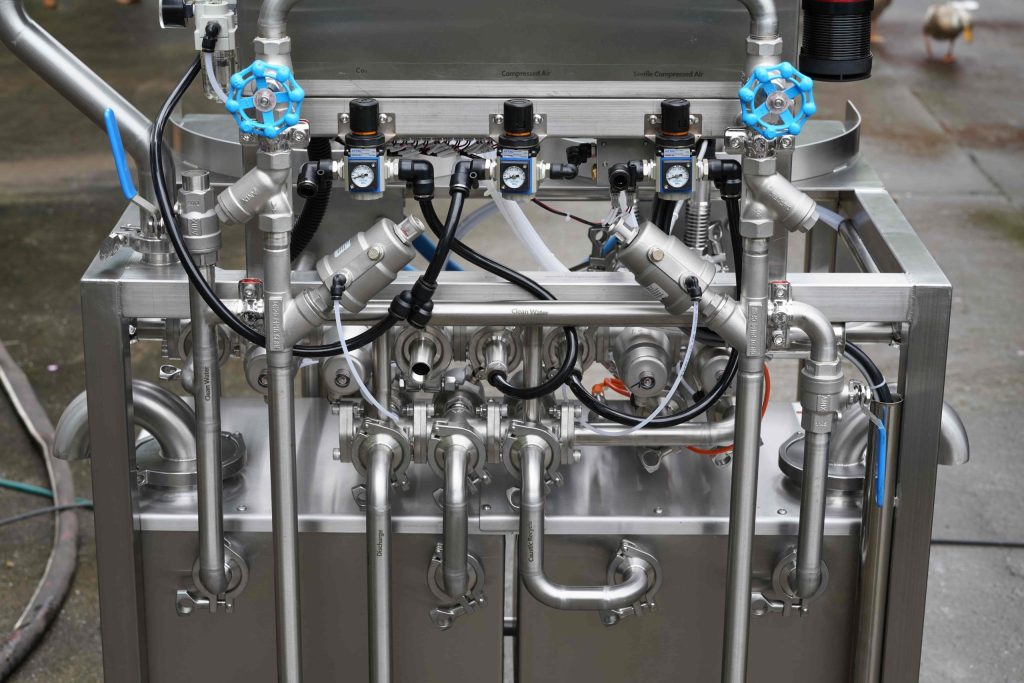

Key Features and Benefits of Commercial Keg Cleaning Machines

This table highlights key features and benefits of commercial keg washers, focusing on their technological advancements, operational efficiency, and safety considerations.

| Recurso | Descrição |

|---|---|

| Automated Cleaning Cycles | Commercial keg washers offer programmable cycles for cleaning, rinsing, and sanitizing kegs. |

| Stainless Steel Build | Most models are constructed from durable stainless steel, ensuring longevity and hygiene. |

| Water and Energy Savings | Advanced systems minimize water and energy consumption compared to manual cleaning methods. |

| Chemical Dosing Systems | Precise dosing of cleaning agents optimizes effectiveness while reducing chemical waste. |

| Modular Design | Modular configurations allow for scalability and customization based on brewery needs. |

| Características de segurança | Built-in safety protocols protect operators from hazards associated with cleaning chemicals. |

| User-Friendly Interfaces | Intuitive controls and displays simplify operation and monitoring of cleaning cycles. |

Conclusão

Investir em um lavadora de barris comercial is a strategic decision for breweries looking to optimize operations, improve cleaning standards, and achieve long-term cost savings. The benefits of automation, including efficiency, improved cleaning quality, and reduced environmental impact, make commercial keg washers indispensable in modern brewery settings. By carefully considering your brewery’s specific needs and operational requirements, you can select a keg washer that enhances productivity and supports sustainable growth.

Perguntas frequentes

P: São commercial keg washers suitable for small breweries?

A: Yes, commercial keg washers come in various sizes and configurations to suit the needs of both small and large breweries. Modular designs allow for scalability as production volumes increase.

Q: How often should a commercial keg washer be serviced?

A: Regular maintenance is crucial. Typically, manufacturers recommend quarterly inspections and routine cleaning of filters and nozzles to ensure optimal performance.

Q: Can a lavadora de barris comercial handle different keg sizes and materials?

A: Yes, most commercial keg washers are designed to accommodate various keg sizes and materials, offering flexibility in cleaning specifications.

Q: What are the energy requirements for operating a commercial keg washer?

A: Energy consumption varies by model and capacity. Many modern keg washers are designed to be energy-efficient, utilizing advanced technologies to minimize operational costs.