Introdução

Investir em equipamentos modernos de limpeza de barris não é apenas uma escolha, mas uma necessidade para cervejarias que se esforçam para manter altos padrões de limpeza e eficiência operacional. Este blog se aprofunda nos benefícios multifacetados da atualização para sistemas avançados de equipamentos de limpeza de barris, enfatizando ganhos de eficiência, economia de custos e melhorias gerais nas operações da cervejaria.

Importance of Clean Kegs

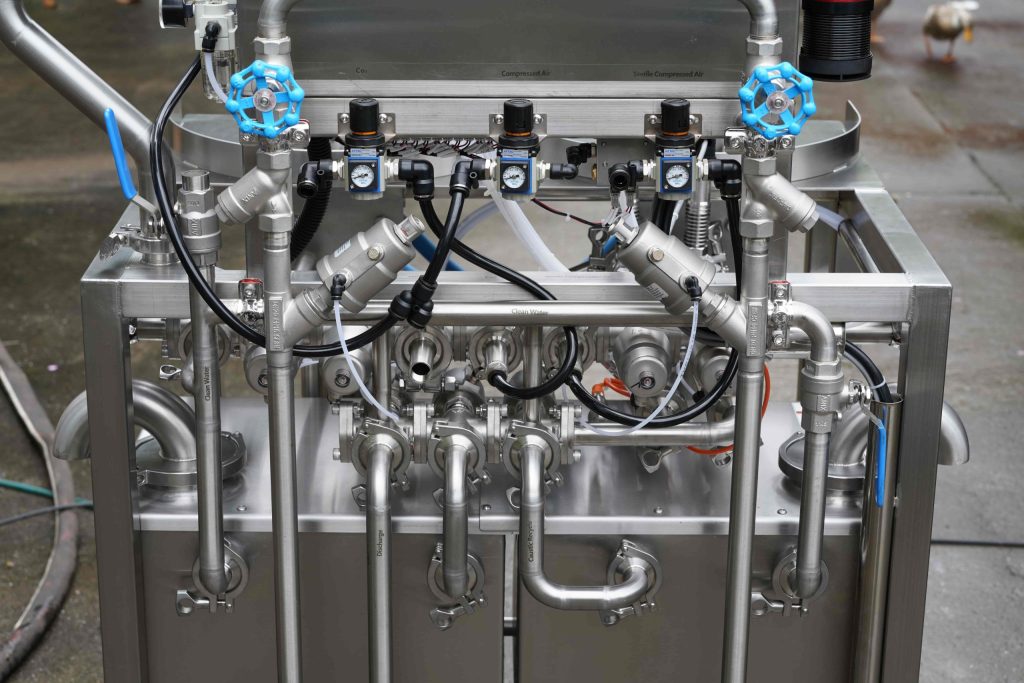

The cleanliness of kegs directly impacts the quality and taste of beer. Any residue, bacteria, or contaminants left in kegs can alter the flavor profile and reduce the shelf life of the beer. Modern keg cleaning equipment is designed to thoroughly clean and sanitize kegs, ensuring that every batch of beer is delivered to customers in optimal condition.

Enhanced Efficiency with Automated Systems

Traditional manual cleaning methods are not only labor-intensive but also prone to inconsistencies. Automated keg cleaning systems revolutionize the cleaning process by automating repetitive tasks and minimizing human error. These systems typically reduce cleaning times significantly, from around 20 minutes per keg with manual methods to as little as 5 minutes per keg with automated systems.

Moreover, automated systems can handle a higher volume of kegs per day, increasing throughput and reducing downtime. For instance, where manual cleaning might limit a brewery to cleaning 50 kegs per day, automated systems can clean up to 150 kegs per day, depending on the specific model and setup. This efficiency boost translates into operational savings and allows breweries to allocate human resources to more value-added tasks.

Efficiency Gains with Automated Keg Cleaning Systems

| Efficiency Metric | Before Automation | After Automation |

|---|---|---|

| Cleaning Time per Keg | 20 minutes | 5 minutes |

| Number of Kegs Cleaned | 50 per day | 150 per day |

| Water and Chemical Usage | Alto | Optimized |

Automated systems also optimize resource usage. They typically use less water and chemicals per cleaning cycle compared to manual methods, contributing to cost savings and environmental sustainability. By minimizing waste and maximizing efficiency, breweries can enhance their overall operational sustainability and reduce their carbon footprint.

Cost Savings and Return on Investment

While the upfront cost of installing modern keg cleaning equipment may seem significant, the long-term cost savings and return on investment (ROI) are substantial. Automated systems reduce labor costs by requiring less manpower for cleaning operations. They also reduce water and chemical usage, which not only saves costs but also aligns with sustainable practices.

Furthermore, automated systems tend to have longer lifespans and lower maintenance requirements compared to traditional manual equipment. This reduces ongoing maintenance costs and downtime due to equipment failure or repairs. As a result, breweries can allocate their financial resources more efficiently, investing in other areas of operations or expansion.

Cost Savings from Modern Keg Cleaning Equipment

| Cost Saving Measure | Estimated Savings |

|---|---|

| Labor Costs | 30% reduction |

| Water and Chemical Usage | 50% reduction |

| Downtime Reduction | 25% decrease |

| Equipment Maintenance | 20% savings |

Ensuring Consistency and Quality Control

Consistency in cleaning protocols is crucial for ensuring beer quality and meeting regulatory standards. Modern keg cleaning equipment offers programmable controls and real-time monitoring capabilities, allowing breweries to maintain strict adherence to cleaning protocols and quality control measures.

Automated systems ensure that every keg undergoes the same thorough cleaning process, eliminating variations that can impact beer quality. Real-time monitoring alerts operators to any deviations or issues during the cleaning cycle, allowing for immediate corrective action. This consistency in cleaning practices not only enhances product quality but also builds consumer trust and brand reputation.

Conclusão

Investing in modern equipamento de limpeza de barris is a strategic decision for breweries aiming to optimize operations, reduce costs, and maintain superior product quality. Automated systems streamline cleaning processes, minimize resource usage, and enhance efficiency, ultimately contributing to sustainable and profitable brewery operations. By prioritizing cleanliness and efficiency, breweries can strengthen their competitive edge in the market and meet the growing demands of consumers for high-quality craft beer.

Perguntas frequentes

Q: What are the primary benefits of automated limpeza de barril systems?

Automated systems reduce cleaning time, minimize labor costs, optimize water and chemical usage, and ensure consistent cleaning standards.

Q: How do modern keg cleaning systems contribute to sustainability?

They reduce water and chemical usage, minimize energy consumption, and extend the lifespan of cleaning equipment, promoting environmentally friendly practices.

Q: Is the initial investment in modern equipamento de limpeza de barris justified?

Yes, the investment typically results in long-term cost savings, improved efficiency, and enhanced product quality, providing a favorable return on investment.