Introdução

Embarcar na jornada de abrir uma microcervejaria é um empreendimento empolgante que exige planejamento meticuloso e investimento substancial. Um aspecto essencial a ser considerado é a seleção de equipamentos de fabricação de cerveja comercial. Os equipamentos de fabricação de cerveja certos podem influenciar significativamente a qualidade, eficiência e escalabilidade da sua produção de cerveja. Este guia abrangente se aprofunda nos equipamentos essenciais de fabricação de cerveja comercial, suas funções e os fatores a serem considerados ao tomar decisões informadas para sua microcervejaria.

Compreendendo o Processo de fabricação de cerveja

Antes de mergulhar nas complexidades dos equipamentos de fabricação de cerveja comercial, é imperativo entender as etapas fundamentais envolvidas no processo de fabricação de cerveja. Essas etapas formam a espinha dorsal da produção de cerveja:

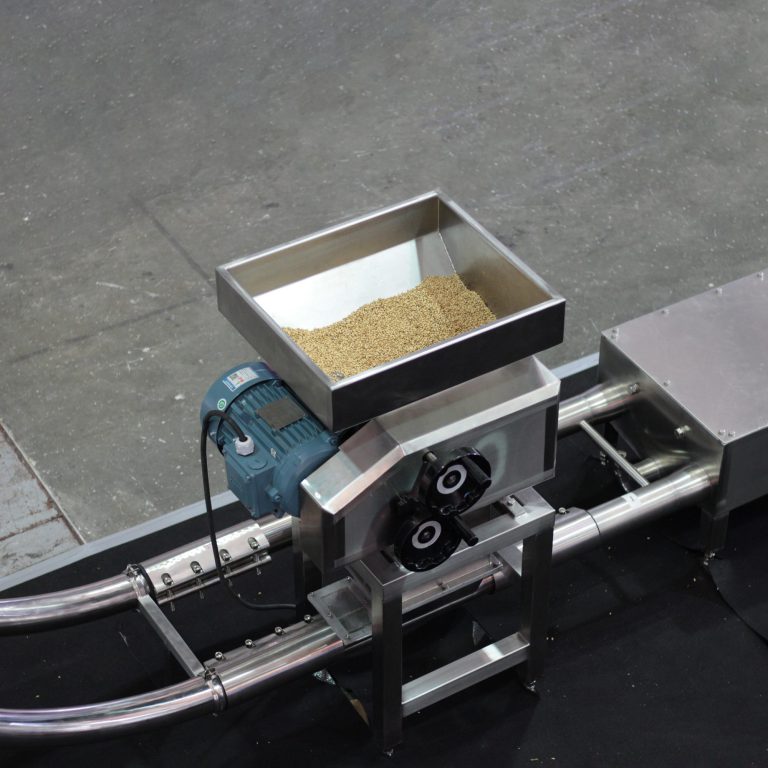

- Moagem: O estágio inicial envolve a trituração dos grãos maltados para expor os amidos, que são essenciais para a conversão subsequente em açúcares.

- Amassamento: Nesta etapa, os grãos triturados são misturados com água quente para iniciar a conversão dos amidos em açúcares fermentáveis.

- Lauteração: O mosto líquido, agora rico em açúcares, é separado do grão gasto, que é um subproduto do processo de mosturação.

- Ebulição: O mosto passa por um processo de fervura para atingir a esterilização, extrair sabores e aromas do lúpulo e concentrar os açúcares.

- Fermentação: A levedura, o ingrediente mágico, é introduzida no mosto, onde converte os açúcares em álcool e dióxido de carbono, os componentes fundamentais da cerveja.

- Condicionamento: A cerveja recém fermentada amadurece e clarifica, permitindo que os sabores se desenvolvam e a cerveja se estabilize.

- Embalagem: A etapa final envolve embalar a cerveja pronta em barris ou garrafas, preparando-a para distribuição e consumo.

Comercial Essencial Equipamentos para fabricação de cerveja

Uma microcervejaria bem equipada requer uma gama de equipamentos essenciais de fabricação de cerveja comercial para facilitar o processo de fabricação de cerveja. Esses componentes principais incluem:

- Moinho de malte: Esta máquina é responsável por triturar grãos maltados até a consistência desejada, garantindo a exposição ideal dos amidos para o processo de mosturação. Um moinho de malte de alta qualidade pode impactar significativamente a eficiência do processo de fabricação de cerveja e a qualidade da cerveja final.

- Purê de batata: Um grande recipiente onde o processo de mosturação acontece. Ele fornece um ambiente controlado para a conversão de amidos em açúcares. O tanque de mosturação é tipicamente equipado com sistemas de controle de temperatura e mecanismos de agitação para garantir condições ideais de mosturação.

- Lauter Tun: Este recipiente é projetado especificamente para separar o mosto do grão gasto. Ele emprega um sistema de filtragem para extrair eficientemente o mosto líquido. O tanque de filtragem é frequentemente equipado com um braço de aspersão para enxaguar os grãos e maximizar a extração do mosto.

- Chaleira de infusão: A chaleira de infusão é um recipiente grande e aquecido onde o mosto é fervido. Esse processo serve para esterilizar o mosto, extrair sabores de lúpulo e concentrar os açúcares. A chaleira de infusão é normalmente equipada com um elemento de aquecimento, um braço de hidromassagem para separação de lúpulo e um resfriador de mosto para resfriar rapidamente o mosto.

- Resfriador de mosto: Um resfriador de mosto é essencial para resfriar rapidamente o mosto quente até a temperatura de fermentação. Esse resfriamento rápido é crucial para evitar o crescimento bacteriano indesejado e preservar os delicados aromas do lúpulo. Trocadores de calor de placas são comumente usados como resfriadores de mosto devido à sua capacidade de resfriamento eficiente.

- Fermentadores: Fermentadores são recipientes onde a mágica da fermentação acontece. Eles fornecem um ambiente controlado para a levedura converter açúcares em álcool e dióxido de carbono. Os fermentadores podem ser cilíndricos-cônicos ou estilo unitank, cada um com suas próprias vantagens e desvantagens.

- Tanque Brilhante: Tanques brilhantes são usados para condicionar e carbonatar a cerveja. Esse processo refina a clareza, o sabor e os níveis de carbonatação da cerveja. Tanques brilhantes são tipicamente equipados com pedras de carbonatação e válvulas de alívio de pressão.

- Sistema de barrilete: Um sistema de kegging é usado para encher barris com cerveja, um método popular para distribuir cerveja para bares e restaurantes. Os sistemas de kegging geralmente consistem em uma lavadora de barris, um enchedor e um sistema de mistura de gás.

- Sistema de engarrafamento: Um sistema de engarrafamento é usado para embalar cerveja em garrafas, um formato conveniente para vendas no varejo e consumo doméstico. Os sistemas de engarrafamento podem ser manuais ou automáticos, e eles normalmente incluem um enxaguador, um enchedor, um tampador e um rotulador.

Escolhendo os equipamentos certos para fabricação de cerveja comercial

Selecionar os equipamentos de fabricação de cerveja comercial apropriados é uma decisão crítica que pode impactar significativamente o sucesso da sua microcervejaria. Vários fatores devem ser cuidadosamente considerados ao fazer essa escolha:

- Capacidade de produção: Avalie sua capacidade de produção desejada para determinar o tamanho e a capacidade dos equipamentos de fabricação de cerveja necessários. Uma capacidade de produção maior pode exigir equipamentos de fabricação de cerveja em larga escala com maior rendimento.

- Orçamento: Estabeleça um orçamento realista para compras de equipamentos de fabricação de cerveja, pois isso influenciará os tipos e a qualidade dos equipamentos de fabricação de cerveja que você pode adquirir. É importante equilibrar o investimento inicial com os benefícios de longo prazo de equipamentos de fabricação de cerveja de alta qualidade.

- Restrições de espaço: Avalie o espaço disponível em sua cervejaria para determinar o layout e o tamanho dos equipamentos de fabricação de cerveja que podem ser acomodados. A utilização eficiente do espaço é crucial, especialmente em cervejarias menores.

- Estilos de cerveja: Considere os estilos específicos de cerveja que você planeja fabricar, pois certos equipamentos de fabricação podem ser mais adequados para estilos específicos. Por exemplo, fabricar lagers pode exigir sistemas específicos de controle de temperatura para o processo de fermentação.

Comparação de diferentes Sistemas de fermentação

| Sistema de fermentação | Vantagens | Desvantagens | Mais adequado para |

|---|---|---|---|

| Sistema de três vasos | Oferece flexibilidade e versatilidade para preparar uma ampla variedade de estilos de cerveja. | Requer mais espaço e pode ser mais complexo de operar. | Cervejarias artesanais com uma variedade diversificada de estilos de cerveja. |

| Sistema de vaso único | Compacto e eficiente, ideal para cervejarias de pequeno porte com espaço limitado. | Menos flexível em termos de produção de diferentes estilos de cerveja. | Pequenas cervejarias com uma linha de cervejas focada. |

| Sistema Grainfather | Sistema completo que simplifica o processo de fermentação, tornando-o adequado para cervejeiros caseiros e nanocervejarias. | Capacidade limitada e pode não ser ideal para produção em larga escala. | Cervejeiros caseiros e nanocervejarias. |

Sistemas de Automação e Controle

Incorporar sistemas de automação e controle ao seu processo de fabricação de cerveja pode aumentar significativamente a eficiência, consistência e precisão. Esses sistemas podem monitorar e controlar parâmetros críticos, como temperatura, pH e níveis de oxigênio, garantindo condições ideais de fabricação de cerveja. Sistemas avançados de automação também podem reduzir os custos de mão de obra e melhorar a produtividade geral.

Manutenção e Limpeza

Práticas rigorosas de manutenção e limpeza são essenciais para preservar a qualidade e a longevidade dos seus equipamentos comerciais de fabricação de cerveja. Procedimentos regulares de limpeza e higienização ajudam a eliminar contaminantes, prevenir o crescimento bacteriano e manter condições higiênicas de fabricação de cerveja. Um sistema de equipamento de fabricação de cerveja bem conservado garantirá uma qualidade consistente da cerveja e minimizará o tempo de inatividade.

Conclusão

A seleção de soluções comerciais adequadas equipamentos de fabricação de cerveja é uma decisão crucial que pode impactar significativamente o sucesso da sua microcervejaria. Ao considerar cuidadosamente fatores como capacidade de produção, orçamento, restrições de espaço e estilos de cerveja desejados, você pode fazer escolhas informadas que se alinham com suas necessidades e objetivos específicos.

Perguntas frequentes

Qual é a diferença entre um tanque de mosturação e um tanque de filtragem?

Um mash tun é um recipiente usado para converter os amidos em grãos maltados em açúcares fermentáveis. Um lauter tun, por outro lado, é usado para separar o mosto líquido do grão gasto após o processo de mosturação.

Qual é a melhor maneira de limpar e higienizar ambientes comerciais? equipamento de fabricação de cerveja?

Limpeza e higienização adequadas são cruciais para manter a qualidade e a segurança da sua cerveja. Um método comum envolve um processo de três etapas: limpeza, higienização e enxágue. A limpeza remove a matéria orgânica, a higienização mata os micro-organismos e o enxágue remove qualquer resíduo químico.

Como escolher o tamanho certo do fermentador?

O tamanho do fermentador que você precisa depende da sua capacidade de produção desejada e dos tipos de cerveja que você planeja fabricar. Considere fatores como tamanho do lote, tempo de fermentação e taxa de rotatividade desejada. Muitas vezes é sensato ter alguma capacidade extra para flexibilidade.

Com que frequência devo substituir meu comercial equipamento de fabricação de cerveja?

A vida útil do equipamento de fabricação de cerveja varia dependendo do uso, manutenção e qualidade do material. No entanto, componentes principais como caldeiras e resfriadores podem precisar de substituição a cada 10-15 anos. A manutenção regular, incluindo limpeza e inspeções, pode estender a vida útil do seu equipamento.

Quais são os benefícios de usar uma chaleira de fogo direto em vez de uma chaleira elétrica ou a gás?

Chaleiras de fogo direto oferecem controle preciso de temperatura e podem fornecer um perfil de sabor único para a cerveja. No entanto, elas exigem uma operação mais qualificada e podem ser menos eficientes em termos de energia do que outros métodos de aquecimento. Chaleiras elétricas e a gás são mais convenientes e fáceis de controlar, mas podem não fornecer o mesmo nível de complexidade de sabor.