Introdução

Os barris são os heróis anônimos da indústria cervejeira, transportando silenciosamente suas preciosas cervejas da cervejaria para a sala de torneiras ou mercado. Para garantir a qualidade ideal da sua cerveja e a longevidade dos seus barris, um processo robusto de limpeza de barris é essencial.

Neste guia abrangente, vamos nos aprofundar no papel crítico dos equipamentos de limpeza de barris, explorar a gama diversificada de opções disponíveis e fornecer conselhos de especialistas sobre como selecionar o equipamento ideal para as necessidades específicas da sua cervejaria. Também discutiremos os inúmeros benefícios de investir em equipamentos de limpeza de barris premium e responderemos a perguntas frequentes.

O imperativo da limpeza do barril

Um processo completo de limpeza de barris é essencial por vários motivos:

- Mantendo a qualidade da cerveja: Um barril imaculado, livre de resíduos de cerveja, fermento ou outros contaminantes, garante o sabor e o aroma ideais para suas cervejas subsequentes.

- Prevenção de contaminação: A limpeza regular inibe o crescimento de bactérias e microrganismos nocivos que podem comprometer a qualidade da cerveja e representar riscos à saúde.

- Aumentando a vida útil do barril: A limpeza e a manutenção adequadas aumentam significativamente a vida útil dos seus barris, resultando em economias substanciais de custos ao longo do tempo.

- Aderindo às Normas Regulamentares: Muitos órgãos reguladores impõem diretrizes rigorosas para a limpeza de barris para garantir a segurança e a qualidade dos alimentos.

Uma visão geral abrangente de Equipamentos de limpeza de barris

O mercado oferece uma variedade de equipamentos de limpeza de barris, cada um com suas vantagens e desvantagens únicas. Os tipos mais comuns incluem:

- Lavadoras de barris manuais: Essas máquinas básicas exigem trabalho manual para desmontar, limpar e remontar os barris.

- Lavadoras de barris semiautomáticas: Essas máquinas automatizam certas etapas de limpeza, como encher e esvaziar o barril, mas ainda exigem intervenção manual.

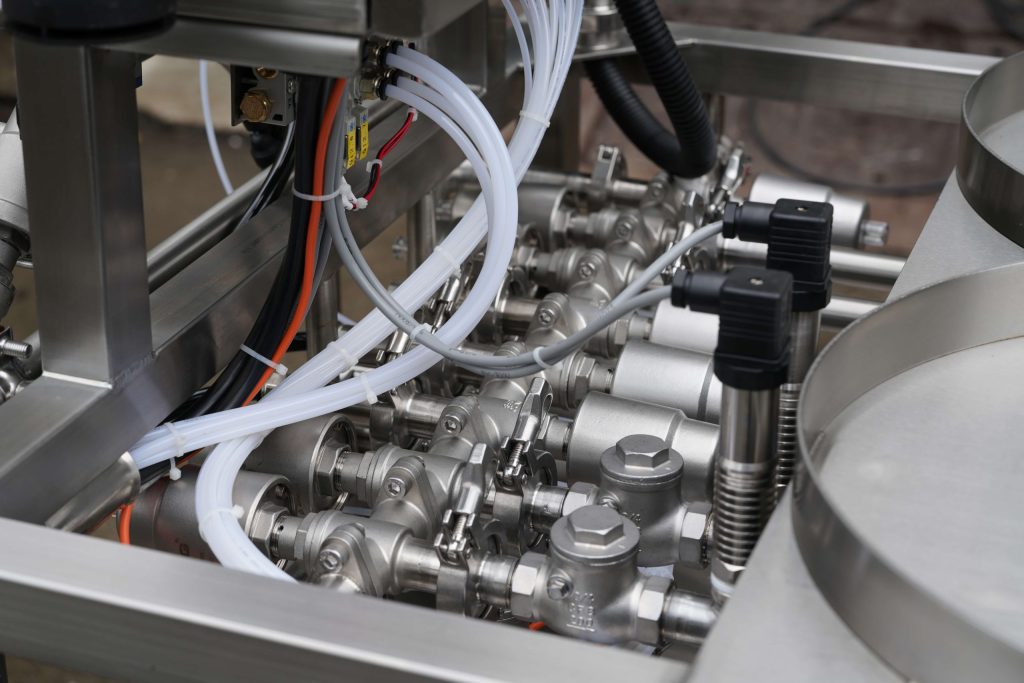

- Lavadoras de barris totalmente automáticas: Essas máquinas avançadas cuidam de todo o processo de limpeza, desde o pré-enxágue até a higienização final, com intervenção humana mínima.

Principais considerações para selecionar equipamentos de limpeza de barris

Ao selecionar equipamentos de limpeza de barris, considere os seguintes fatores cruciais:

- Volume do barril: O tamanho dos seus barris afeta diretamente a capacidade necessária do seu equipamento de limpeza.

- Rendimento: O número de barris que você precisa limpar por hora determina a velocidade e a eficiência necessárias do equipamento.

- Agentes de limpeza: Os tipos de agentes de limpeza utilizados influenciam os materiais e o design do equipamento.

- Orçamento: O custo dos equipamentos de limpeza de barris varia significativamente, portanto, é essencial estabelecer um orçamento antes de fazer uma compra.

As vantagens de investir em Premium Equipamentos de limpeza de barris

Investir em equipamentos de limpeza de barris premium oferece uma infinidade de benefícios, incluindo:

- Eficiência aprimorada: Sistemas automatizados reduzem drasticamente o tempo e o trabalho necessários para a limpeza dos barris.

- Consistência melhorada: Processos de limpeza consistentes levam a resultados mais confiáveis e repetíveis.

- Redução do consumo de água e produtos químicos: Equipamentos eficientes minimizam o uso de água e produtos químicos.

- Vida útil estendida do equipamento: Equipamentos de alta qualidade são feitos para suportar uso pesado e durar mais.

Uma análise comparativa de sistemas de lavagem de barris

| Recurso | Lavadora de barris manual | Lavadora de barris semiautomática | Lavadora de barris totalmente automática |

|---|---|---|---|

| Nível de automação | Baixo | Médio | Alto |

| Requisitos de mão de obra | Alto | Médio | Baixo |

| Capacidade de transferência | Baixo | Médio | Alto |

| Custo inicial | Baixo | Médio | Alto |

| Custo operacional | Baixo | Médio | Alto |

Implementando um Robusto Limpeza de barril Programa

Para maximizar a eficácia do seu programa de limpeza de barris, considere as seguintes práticas recomendadas:

- Desenvolva um Procedimento Operacional Padrão (POP) abrangente: Um SOP detalhado descreve as etapas envolvidas no processo de limpeza, garantindo consistência e eficiência.

- Invista em treinamento completo da equipe: O treinamento adequado capacita seus funcionários a entender a importância da limpeza dos barris e a seguir o POP com precisão.

- Priorize a qualidade da água: A qualidade da sua água impacta significativamente a eficácia do seu processo de limpeza. Considere usar amaciadores de água ou filtros para melhorar a qualidade da água.

- Realizar inspeções regulares de equipamentos: Inspeções regulares ajudam a identificar possíveis problemas com seus equipamentos de limpeza de barris e evitam quebras dispendiosas.

Conclusão

Ao investir em premium equipamentos de limpeza de barris e implementando um programa de limpeza abrangente, você pode garantir que sua cerveja atinja consistentemente seu potencial máximo. Isso não apenas melhora a qualidade do seu produto, mas também estende a vida útil dos seus barris e reduz os custos operacionais gerais.

Perguntas frequentes

Quais são os diferentes tipos de equipamento de limpeza de barris?

Equipamentos de limpeza de barris podem variar de lavadoras manuais simples a sistemas totalmente automatizados. Os tipos mais comuns incluem lavadoras de barris manuais, semiautomáticas e totalmente automáticas.

Com que frequência devo limpar meus barris?

A frequência da limpeza do barril depende de vários fatores, como uso, condições de armazenamento e regulamentações locais. Geralmente, os barris devem ser limpos e higienizados após cada uso para manter a qualidade ideal da cerveja.

Quais produtos de limpeza devo usar para meu equipamento de limpeza de barris?

Os agentes de limpeza apropriados para equipamentos de limpeza de barris dependem dos contaminantes específicos e do tipo de equipamento. Os agentes de limpeza comuns incluem detergentes alcalinos, limpadores ácidos e sanitizadores. É crucial seguir as recomendações do fabricante e as regulamentações locais.