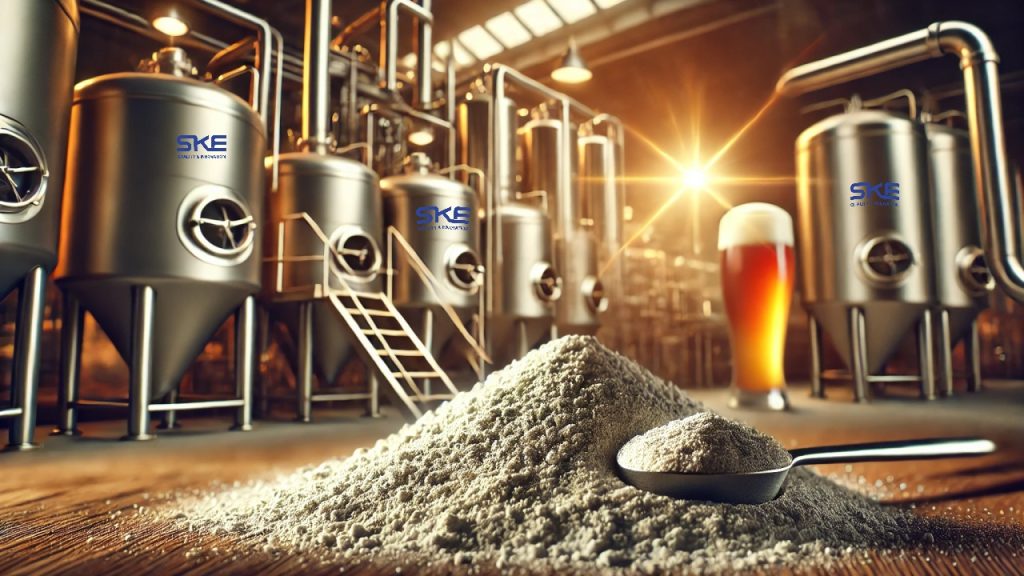

Brewers, unite! In today’s dynamic beverage world, brewers are reinventing tradition—crafting everything from hoppy ales to crisp non alcoholic beer—and redefining what a brewing company can be. At the heart of this revolution lies one humble ingredient: malt. When paired with precision gear from SKE, these four pillars—brewers, non alcoholic beer, brewing company, and malt—become the cornerstones of innovation.

The Emotional Journey of Modern Brewers

Every brewer knows the thrill of unlocking a new recipe—watching simple grains transform into complex flavors. Yet behind that joy lies countless late nights, trial-and-error batches, and the relentless pursuit of perfection. Whether you’re a solo homebrewer or part of a global brewing company, the passion is the same: crafting beverages that connect people.

When the world shut down, many brewers pivoted to non alcoholic beer, determined to offer comfort without compromise. It wasn’t just about removing alcohol—it was about preserving the heart and soul of beer, from the earthy notes of malt to the bright dance of yeast. Today’s non alcoholic beer can rival its alcoholic counterparts, thanks to innovative techniques and, importantly, reliable equipment from SKE.

Why Non Alcoholic Beer Matters to Brewers

Inclusivity: Today’s consumers seek mindful alternatives—people in recovery, designated drivers, or health-conscious friends still crave the camaraderie of a cold pint. Non alcoholic beer lets brewers include everyone at the table.

Flavor Preservation: With top-tier malt selection and temperature control, non alcoholic beer can maintain that signature mouthfeel and depth. SKE’s fermenters ensure every grain’s character shines through, even sans alcohol.

Market Growth: The global non alcoholic beer market is projected to hit $25 billion by 2027, making it an essential offering for any forward-thinking brewing company.

Malt: The Soul of Every Brewing Company

No discussion of beer is complete without malt. It’s the backbone—the source of color, sweetness, and body. From caramel-rich crystal malt to robust roasted barley, each variety tells a story:

Pale malt for clean, drinkable bases

Vienna malt adding subtle toastiness

Chocolate malt delivering bittersweet depth

For brewers, sourcing exceptional malt is non-negotiable. A reputable brewing company knows that investing in quality malt pays dividends in taste—and that investment extends to equipment. SKE brewing systems are engineered to handle delicate mash conversions, protecting the nuanced profiles of each malt.

How SKE Empowers Brewers and Brewing Companies

When you partner with SKE, you’re not just buying tanks—you’re gaining reliability:

Precision Mash Tuns: Maintain ideal temperatures for enzyme activity, unlocking the full potential of your malt.

Automated Fermenters: Guard your non alcoholic beer yeast strains with consistent fermentation cycles.

CIP Systems: Keep lines sterile between batches, reducing downtime and preventing cross-flavor contamination.

For modern brewing companies, these advantages translate to smoother production, fewer wasted batches, and the freedom to focus on creativity rather than constant troubleshooting.

Real Stories from Brewers

Anna, head brewer at a small urban brewery, switched to SKE equipment to scale her non alcoholic beer line. “My original batches lacked punch, but after upgrading to SKE’s conical fermenters, our new amber non alcoholic beer has a richness we didn’t think possible,” she shares.

Liam, co-founder of a family-run brewing company, credits their expansion to SKE’s turnkey systems: “We tripled our non alcoholic beer output in three months—our community can’t get enough.”

These testimonials highlight how the right gear and high-quality malt can transform a brewery’s trajectory.

Practical Tips for Brewers

Optimize Your Mash: Use a reflux mash tun from SKE to achieve precise malt conversion—your non alcoholic beer will thank you.

Monitor Fermentation: Equip your tank with digital sensors to track gravity and temperature for every batch.

Rotate Malt Varieties: Experiment with specialty malt in small batches to discover unique flavor profiles.

Embrace NEIPA Trends: Even in non alcoholic beer, hop-forward, hazy styles sell—ensure your equipment handles high-gravity mashes.

Invest in Training: A well-trained team uses SKE systems more effectively, reducing errors and elevating the brewery’s reputation.

Crafting the Future of Brewing

The world of beer is broader than ever. Brewers embracing non alcoholic beer and leveraging quality malt are leading their brewing companies into uncharted territory. By integrating SKE’s advanced equipment, you ensure every brew—from light session beers to robust non-alcoholic stouts—meets the highest standards.