Cabinet Pasteurizer

SKE pasteurizer cabinet is made of stainless steel 304 material, utilizes a built-in steam boiler to supply 98°C steam in the chamber for sterilization of bottled and canned beer, milk and other beverages. Cabinet interior sterilization temperature and time can be adjusted and temp is automatic controlled during pasteurization, has wide range of applications.

Parameter of Single Pallet Cabin

- Total Dimensions (Cabin): 1100*1050*1870mm

- Internal Cart Dimensions: 660*915*1720mm

- Approximate Weight: 600kg

- Temp Range: 60-93℃

- Pressure: 1.0 bar

- Capacity: Customized qty of bottles/cans per batch

- Heating Source: External boiler (Customer provide); Internal electric boiler;Internal gas boiler

Parameter of Double-Pallets Cabin

SKE pasteurizer cabinet is made of stainless steel 304 material, utilizes a built-in steam boiler to supply 98°C steam in the chamber for sterilization of bottled and canned beer, milk and other beverages. Cabinet interior sterilization temperature and time can be adjusted and temp is automatic controlled during pasteurization, has wide range of applications.

- Total Dimensions (Cabin): 2100*1050*1870mm

- Internal Cart Dimensions: 660*915*1720mm for Each Cart

- Approximate Weight: 700kg

- Temp Range: 60-93℃

- Pressure: 1.0 bar

- Capacity: 840 x 330ml bottles/cans per batch;600 x 500ml bottles/cans per batch

- Heating Source: Internal electric boiler

Advantages

- Accurate control of pasteurization temperature and time.

- 360 ° steam surround sterilization, heat uniformity.

- Max working pressure 1.0 bar, no risk of bottles burst.

- Sanitary & compact module works stable operation, low maintenance.

- Water automatic supply protection & anti-dry heating protection.

- Meet QS & CE & UL & CCC & IS9001 certification.

- Dual temperature sensors to detect pasteurization temps.

- Supply cooling water to cool the beverage down after pasteurization.

- Unique designed stainless steel mobile pallet truck, easy to operate.

PU Value

Effectively controlling the PU value is the key to the operation of the system. Too high sterilization temperature or too long sterilization time will produce serious oxidation odor. At the same time, many flavor substances will be damaged, and protein denaturation will also be caused, thus affecting the stability of beer colloid and foam. Insufficient sterilization temperature or too short sterilization time will lead to low PU value, and certain biological stability (i.e. shelf life) cannot be guaranteed.

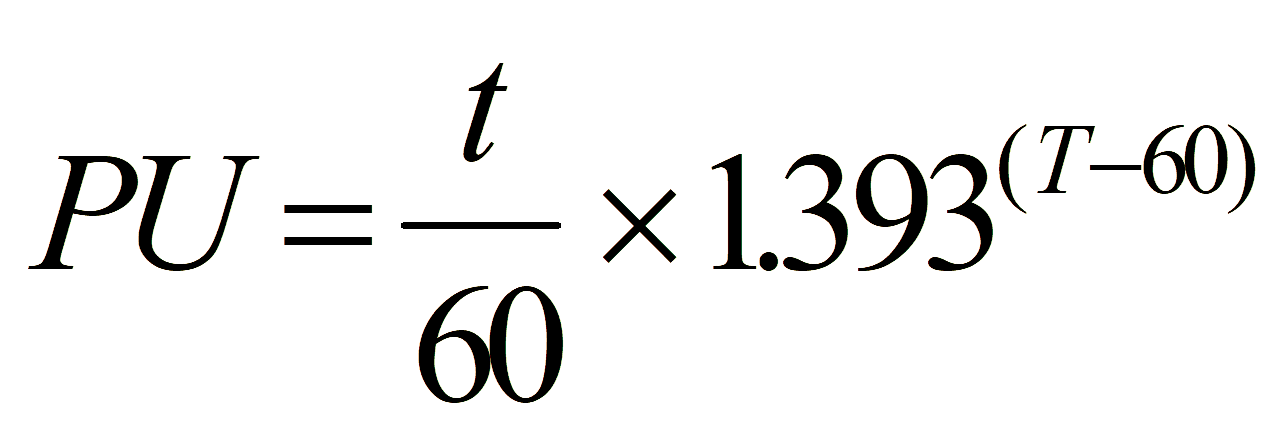

The required heat treatment is achieved through a combination of temperature and holding time. This level of pasteurization is quantified as Pasteurization Units (PU) and calculated as follows:

1.'t' is the holding time in seconds

2.'T' is the pasteurization temp in°C

Total Pasteurization Process Time: Approximate 1 hour/batch

- HeatingPhase: Temperature ramp, Ambient → 70+°C within 30-40minutes

- Holding Phase: Temperature maintenance, At pasteurization temp for 5-10minutes

- Cooling Phase: Temperature reduction: 70+°C → Ambient within 10-20minutes