Welding Technology has evolved into a precision craft, and nowhere is that more evident than in ASME Welding certification. Imagine wielding an argon torch with such mastery that your butt welding and fillet welding joints pass the toughest pressure tests—perhaps even the demanding single-sided welding and double-sided molding exam! Ready to uncover how to tackle these challenges, from mastering complex TIG techniques to coordinating two-person double-sided argon arc welding? Dive into our comprehensive guide:

Contents

Click a section to jump straight to the expert insights—your path to ASME certification mastery starts here!

What Is an ASME Welder Certificate & Where Is It Used?

An ASME welder certificate verifies you can produce welds that meet the American Society of Mechanical Engineers’ Boiler & Pressure Vessel Code (BPVC). Certified welders work on:

Pressure Vessels & Boilers in power generation

Oil & Gas Piping for refineries and pipelines

Chemical Processing Equipment like reactors and distillation columns

Food & Beverage Systems, including stainless-steel fermenters (SKE Equipment featured at Fine Food Australia)

Pharmaceutical Vessels requiring sterile, leak-free joints

This certification demonstrates proficiency in multiple welding processes—opening doors to high-value projects and roles worldwide.

Mastering Single-Sided Welding & Double-Sided Molding

One of the most demanding ASME tests is the single-sided weld that’s back-gouged and filled to form a double-sided mold. The workflow:

Root Pass (Single Side)

Use TIG or SMAW on a 3/8″ plate.

Goal: 100% root penetration without burn-through.

Back-Gouge & Clean

Remove root reinforcement via mechanical or air-carbon arc gouging.

Wire-brush to bare metal.

Double-Sided Fill & Cap

Perform fill passes on both sides, ending with a smooth cap bead.

SKE Equipment’s backing bars ensure uniform support.

| Step | Focus | Common Pitfall |

|---|---|---|

| Root Pass | Full fusion, no burn-through | Inconsistent travel speed |

| Back-Gouge & Clean | Expose fresh metal, remove slag | Damaging base metal |

| Double-Side Fill/Cap | Uniform profile, correct reinforcement | Overheating and warping |

Key Challenge: Controlling heat input to avoid distortion while ensuring full fusion on both faces—tools like SKE’s thermal clamps and interpass temperature monitors make this achievable.

Challenges in Double-Sided Molding

Although the steps are clear, practical hurdles include:

Heat Management: Excessive heat warps thin plates; insufficient heat causes lack of fusion.

Alignment: Misaligned backing bars lead to root defects and rework.

Slag Inclusion: Incomplete slag removal traps impurities.

Solution: Use SKE Equipment’s adjustable fixtures and integrated temperature feedback to maintain optimal conditions throughout the weld.

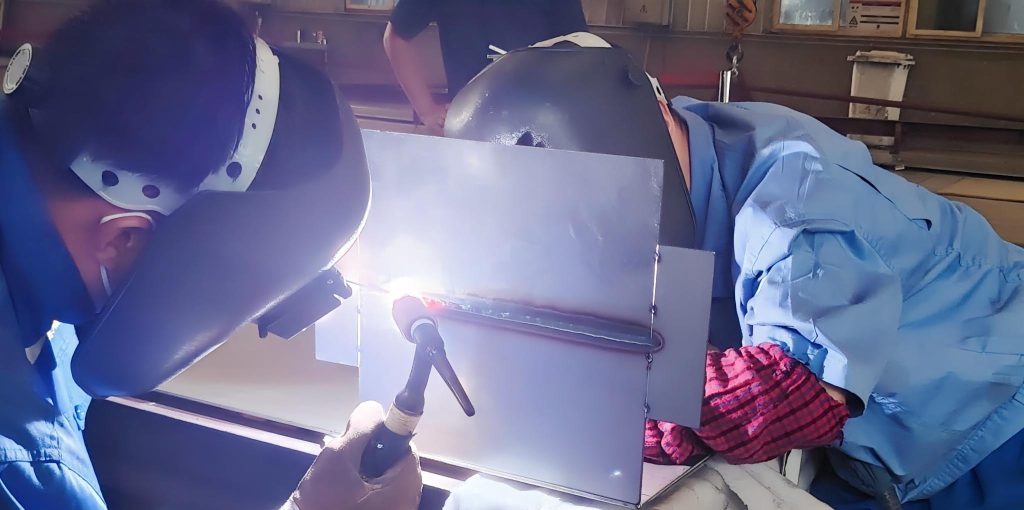

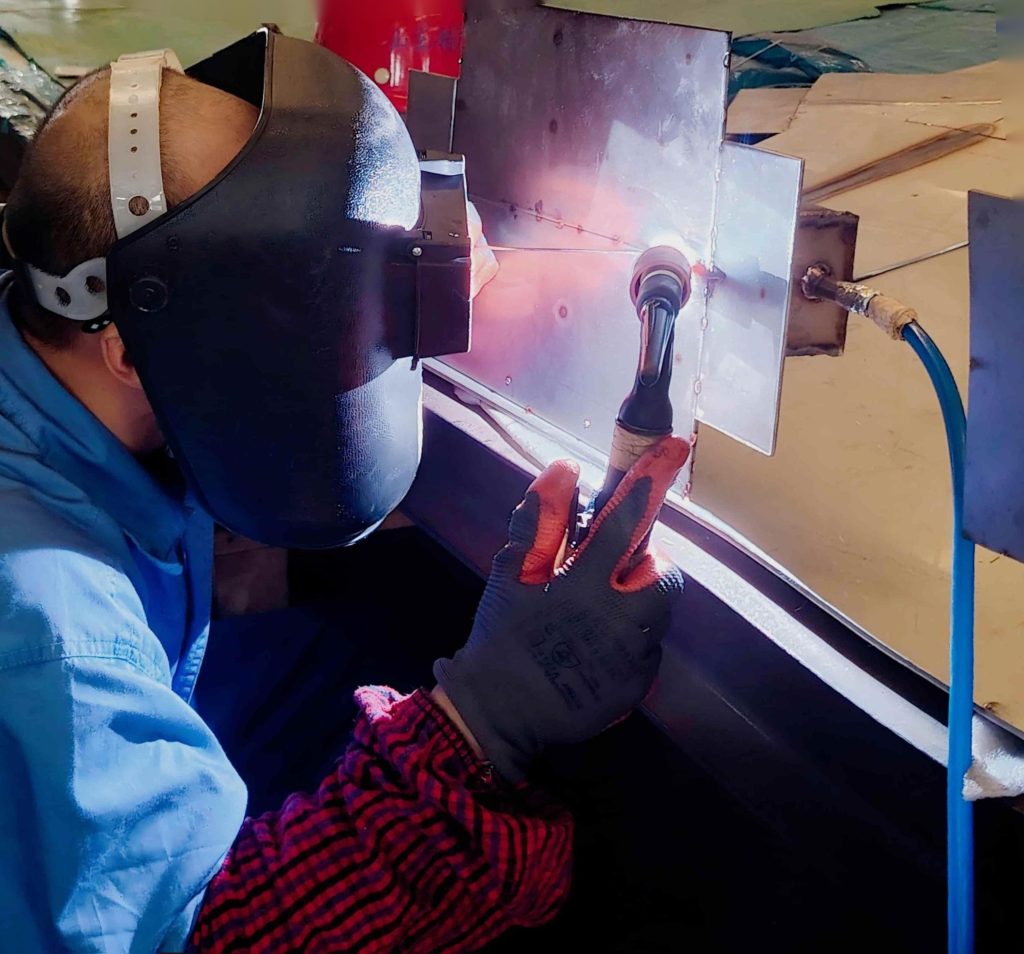

Two-Person Double-Sided Argon Arc Welding

For thick sections (>1″), ASME permits two-person double-sided TIG welding:

| Role | Responsibility | Recommended Tooling |

|---|---|---|

| Welder A | Front-side root and hot-tacking | TIG torch with gas lens |

| Welder B | Backside fill and cap | Synchronized power source |

Process Overview:

Tack Alignment: Precisely position the joint with SKE’s V-block clamps.

Coordinated Root Pass: Welders maintain identical travel speeds via synchronized foot pedals.

Alternate Fills & Caps: Each welder alternates passes, finishing with a merged cap bead.

Common Pitfalls:

Heat imbalance causing warping

Miscommunication leading to fusion gaps

Gas lens misalignment resulting in porosity

SKE Equipment’s dual-torch carts and gas distribution panels ensure both welders operate under identical conditions.

Butt Welding vs. Fillet Welding: Key Differences

Understanding when to use butt welding versus fillet welding is essential for both exams and real applications:

| Feature | Butt Welding | Fillet Welding |

|---|---|---|

| Joint Configuration | Edge-to-edge with bevels | Two plates at approx. 90° |

| Penetration | Full penetration | Partial, defined by throat thickness |

| Applications | Pipe spools, plate splices | Nozzles, structural brackets |

| Inspection Method | Radiographic (RT)/Ultrasonic (UT) | Ultrasonic (UT)/Magnetic particle |

| Fit-Up Tolerance | ±1/32″ root gap | ±1/16″ leg length |

SKE Equipment’s precision V-blocks and edge-prep clamps guarantee the tight tolerances required for both weld types.

Pressure Testing: Best Practices & Pitfalls

After welding, ASME Section IX requires leak-proof verification via:

| Test Type | Advantages | Cautions |

|---|---|---|

| Hydrostatic | Water shows clear leaks | Requires drainage; corrosion risk |

| Pneumatic | No fluid handling; quick setup | Higher safety hazard; less visible leaks |

Best Practices:

Install relief valves set below test pressure

Purge all trapped air to avoid false positives

Compensate for thermal expansion when calculating pressures

SKE Equipment’s calibrated test stands and inline regulators simplify compliant pressure verification.

Conclusion

Ready to elevate your welding craft and conquer your ASME certification with confidence? Partner with SKE Equipment—featuring industry-leading fixtures, thermal clamps, and synchronized TIG carts—to ensure you pass every butt welding, fillet welding, and double-sided argon arc welding challenge with flying colors.

👉 Book Your Free Welding Demo: Contact SKE Equipment

📘 Download Our ASME Welding Toolkit: Get Your Copy

Forge your future with precision—your path to ASME mastery starts today! 🚀