ASME welder certificate examinations set the global standard for professional welders—and few places embody that rigor better than the SKE Equipment certification floor. Curious about what truly happens when skilled welders face off against stainless-steel test plates? From advanced Welding Technology to the finesse of Butt welding, Fillet welding, Single-sided welding and double-sided molding, and the ballet-like coordination of Two-person double-sided argon arc welding, this exam pushes every candidate to their limits. Ready to dive in?

📑 Table of Contents

What Is an ASME Welder Certificate?

A Sneak Peek at the SKE Equipment Exam Floor

Mastering Single-Sided Welding & Double-Sided Molding

Butt vs. Fillet Welding: Key Differences

Two-Person Double-Sided Argon Arc Welding Explained

Pressure Testing: The Ultimate Proof Test

Common Challenges & Pro Tips

Why SKE Equipment Leads the Welding World

With this roadmap in hand, you’ll follow each step of the certification journey—understanding not just what welders do, but why every spark, every bead, and every pressure test matters. Let’s get started!

What Is an ASME Welder Certificate, and Why Does It Matter?

The ASME welder certificate is an industry-recognized credential issued by the American Society of Mechanical Engineers. It verifies a welder’s ability to meet strict standards in both technique and safety. Certified welders are eligible to work on pressure vessels, piping systems, and critical infrastructure projects—sectors where failure is not an option.

Certified welders often find roles in:

Petrochemical refineries

Power generation plants

Shipbuilding yards

Food and beverage processing (including breweries using SKE Equipment tanks)

Pharmaceutical facilities

This credential opens doors to high-stakes projects and better compensation, making the rigorous exam at SKE Equipment a career-defining milestone.

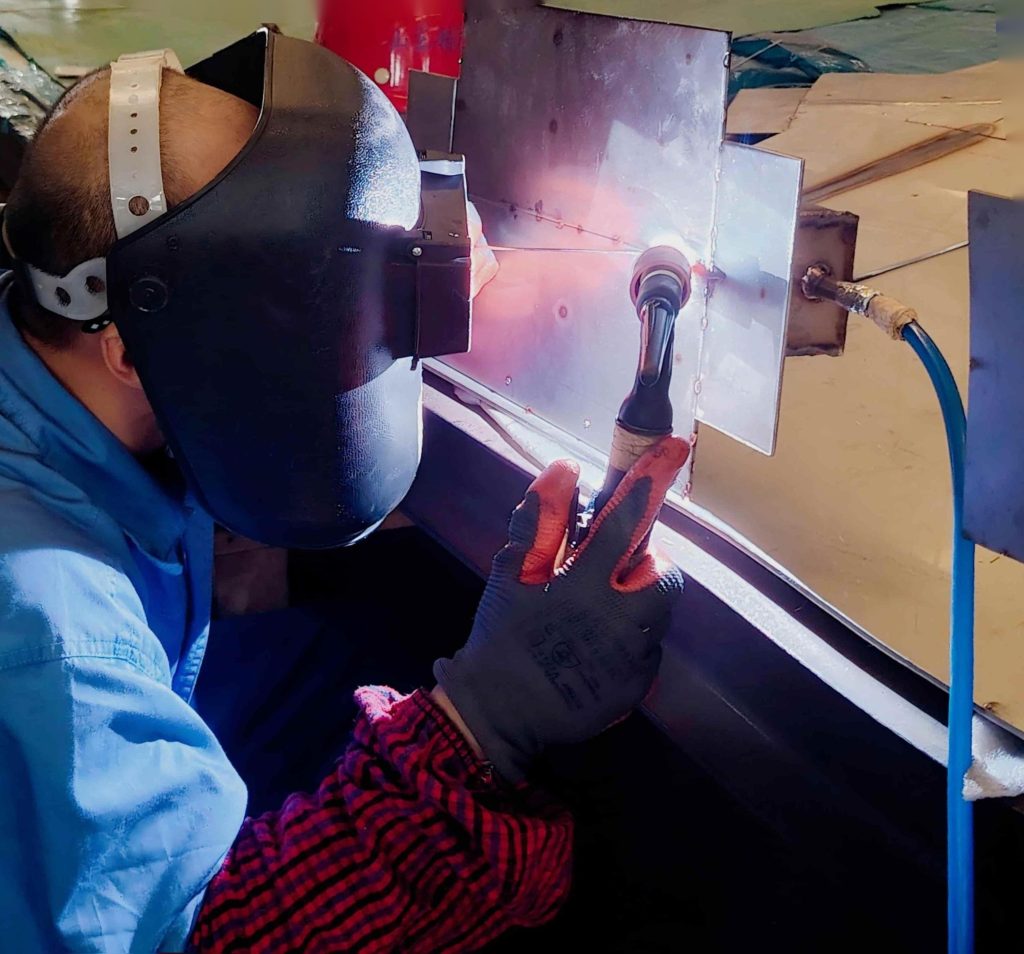

Opening the Door: A Sneak Peek at the SKE Equipment Exam Floor

Imagine stepping onto the shop floor and seeing rows of shiny stainless-steel test plates, each marked with exam IDs. The air hums with welding machines calibrated to the latest Welding Technology standards. Candidates in flame-retardant helmets move with deliberate focus, navigating from one test station to the next.

What makes this environment pulse with excitement? It’s the blend of tradition and innovation:

Laser-aligned fixtures ensure perfect plate positioning.

Digital weld-parameter monitors display amperage and voltage in real time.

A dedicated “quiet zone” for judges to review completed welds under polarized light.

Single-Sided Welding and Double-Sided Molding: Step-by-Step

One of the core tests is Single-sided welding and double-sided molding, a technique that demands flawless penetration and finish on both sides of the joint. Here’s how it unfolds:

| Step | Description | Key Challenge |

|---|---|---|

| 1 | Secure plate in fixture with laser alignment | Zero tolerance for misalignment (±0.1 mm) |

| 2 | Perform first pass (root weld) on one side | Achieving full penetration without burn-through |

| 3 | Flip plate and clean root weld | Removing slag without gouging the root |

| 4 | Apply second pass (molding) to opposite side | Matching bead profile exactly |

| 5 | Inspect both sides under polarized light | Identifying minute porosity or cracks |

Navigating these steps under exam conditions tests not only manual skill but also understanding of metallurgy and heat control.

The Art and Science of Butt Welding vs. Fillet Welding

Understanding the difference between Butt welding and Fillet welding is critical for the exam:

Butt Welding joins two pieces end-to-end in the same plane. It demands precise gap control and root pass quality to withstand axial stresses.

Fillet Welding creates a triangular bead between two surfaces at right angles. It requires balancing throat thickness and leg size to resist shear and bending forces.

“Fillet welds may look simpler, but a slight underfill or overlap can reduce joint strength by up to 30%,” notes SKE Equipment’s head examiner.

Two-Person Double-Sided Argon Arc Welding: A Choreography of Coordination

Perhaps the most dramatic portion of the exam is the Two-person double-sided argon arc welding test. Two welders work in concert: one managing the tungsten electrode, the other feeding the filler rod. Success hinges on:

Synchronized travel speed

Matching electrode-to-plate angles

Consistent argon shielding flow rates

Common pitfalls include “tandem forging,” where wires burn back, and “shield bleed,” causing oxidation on the root side. At SKE Equipment, candidates rehearse such scenarios thousands of times during preparatory courses.

Pressure Testing: Ensuring the Weld Holds Under Fire

After welding, each joint undergoes hydrostatic or pneumatic pressure testing up to 1.5× the design pressure. Critical checkpoints include:

Gradual pressurization to spot slow leaks.

Holding period (typically 30 minutes) while judges monitor gauge stability.

Visual and ultrasonic inspection for micro-fractures.

A single drop of pressure or a hairline crack can cost an entire test—and potentially the candidate’s certification.

Common Challenges and Pro Tips from the SKE Equipment Judges

Alignment Drift: Even slight jig movements can misalign plates.

Pro Tip: Re-zero fixtures between passes.

Heat Input Variability: Too much heat warps thin plates, too little causes lack of fusion.

Pro Tip: Pre-program weld parameters and monitor amperage in real time.

Inter-Pass Cleaning: Residual slag can trap moisture, leading to porosity.

Pro Tip: Always clean with stainless-steel brushes and blow-dry before the next pass.

Bringing It All Together: Why SKE Equipment Leads the Way

By hosting the ASME welder certificate exam on its floor, SKE Equipment demonstrates its commitment to advancing Welding Technology. Candidates benefit from:

State-of-the-art facilities calibrated to ASME standards

Expert instructors who have passed the same tests they administer

Real-world pressure-test rigs mirroring industrial applications

The result is a grueling but fair exam that produces welders capable of tackling the toughest infrastructure projects—whether building pressure vessels, pipelines, or SKE Equipment’s own brewery and distillery systems.

Whether you’re a seasoned welder or an industry observer, the precision, practice, and pressure of SKE Equipment’s ASME welder certificate exam offer invaluable insights into the art and science of welding. From Butt welding to Two-person double-sided argon arc welding, every technique underscores the fusion of human skill with cutting-edge Welding Technology—and sets the gold standard for craftsmen everywhere.