”

Introduction

Brewing your own beer at home through an all grain home brewing system opens up a world of flavors and possibilities. Unlike extract brewing, all grain brewing allows you to craft beer from scratch, utilizing grains, hops, water, and yeast. This method offers more control over the brewing process and the end product, making it the preferred choice for many home brewing enthusiasts.

Benefits of All Grain Brewing

Choosing an all grain home brewing system comes with myriad benefits, such as:

- Flavor Control: You have the power to influence every aspect of the flavor profile by choosing specific grains.

- Cost Effectiveness: Although it requires an initial investment, brewing in bulk lowers the cost per batch significantly.

- Creative Freedom: Experiment with different recipes and techniques freely without restrictions inherent in extract brewing.

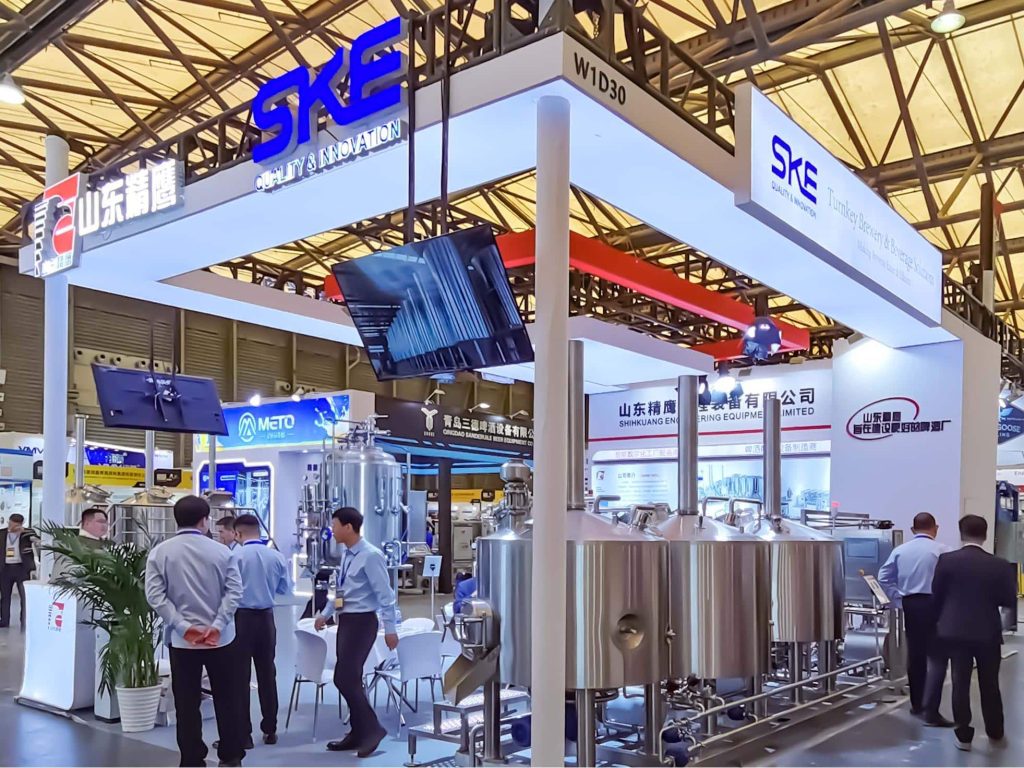

For high-quality brewing equipment, consider exploring SKE’s wide range of home brewing products tailored for enthusiasts who wish to upgrade their brewing experience.

Essential Equipment

To start your all grain brewing journey, you’ll need specific equipment. Here’s what you should have:

- Mash Tun: A vessel where grains are combined with hot water to extract sugars.

- Boil Kettle: Used to boil the wort, adding hops and other ingredients.

- Fermentation Vessel: Where the wort is fermented by yeast to produce alcohol.

- Cooling System: Rapidly cool down your wort post-boiling to prevent unwanted bacteria growth.

- Bottling Equipment: Essential for transferring your beer into bottles without contamination.

SKE provides a variety of home brewing systems and accessories that cater to all your brewing needs. Check our offerings for also specialized components that can enhance your experience.

Brewing Process

The brewing process in an all grain home brewing system can be broken down into several key steps:

Step 1: Mashing

Grains are heated in water to convert starches to sugars. This typically lasts for about an hour.

Step 2: Sparging

After mashing, the liquid known as wort is separated from the grains, often using a sparge method to extract as much sugar as possible.

Step 3: Boiling

The wort is then boiled and hops are added for flavor. This process usually lasts about an hour.

Step 4: Fermentation

Once the wort cools, it’s transferred to the fermentation vessel and yeast is added for fermentation.

Step 5: Bottling

After fermentation, the beer can be bottled or kegged, carbonated, and then stored for maturation.

For more tips on optimizing your brewing process, refer to our brewing tips page for valuable insights and product recommendations.

Common Issues and Solutions

Even the most prepared home brewer can encounter issues. Here are some troubles you might face along with their solutions:

1. Stuck Mash

Occasionally, the mash can become too thick. To remedy this, stirring and adding a bit of hot water can help.

2. Off Flavors

Off flavors can result from poor sanitation practices. Always sanitize all equipment thoroughly.

3. Low Efficiency

If the sugars are not extracting well, consider adjusting your grain crush or closely monitoring your mash temperature.

For detailed support on specific brewing challenges, our common brewing issues page offers expert advice and solutions that can enhance your home brewing experience.

FAQ

What is an all grain home brewing system?

An all grain home brewing system refers to brewing beer directly from malted grains, allowing for greater control over the flavor and brewing process compared to extract brewing.

Is all grain brewing more difficult than extract brewing?

While all grain brewing involves more steps and requires more equipment, many brewers find it rewarding due to the control it provides over the brewing process.

What equipment do I need for all grain brewing?

Essential equipment includes a mash tun, boiling kettle, fermentation vessel, cooling system, and bottling equipment. SKE offers a range of products to meet these needs.

“