”

As a leading provider of equipment tailored for brewing industries, SKE Equipment offers insights and solutions to streamline the brewing process. Understanding the essentials of automated beer brewing not only benefits large commercial breweries but also craft brewers looking to scale their operations.

Benefits of Automated Beer Brewing

Automation in brewing brings significant benefits, making it a game-changer in the industry. Firstly, it enhances consistency—every batch can potentially taste the same, leading to improved customer satisfaction. Furthermore, it increases efficiency; brewers can save time by minimizing manual labor and decreasing human error. Automated systems also offer precise temperature control and ingredient management, which are vital for achieving desired flavor profiles.

Implementing automation in your brewing process not only leads to operational efficiencies but allows for more time to focus on creativity and innovation. As you consider automated beer brewing solutions, check our [case studies](https://skeequipment.com/case-studies) that showcase successful brewery transformations.

Key Components of Automated Systems

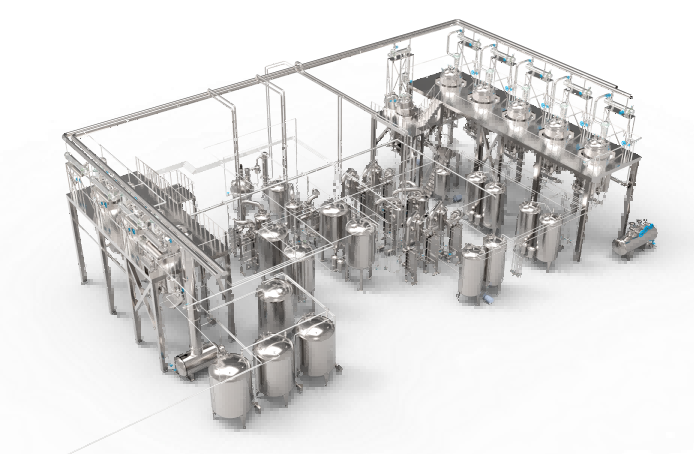

Understanding what makes up an automated beer brewing system is crucial for any brewery looking to invest in this technology. Key components include programmable logic controllers (PLCs), sensors, and monitoring software. PLCs serve as the brain of the system, regulating various brewing processes. Sensors provide real-time data on temperatures and pressure, ensuring optimal conditions for fermentation.

Additionally, integrated software solutions allow brewers to track recipes and adjust parameters remotely, offering unprecedented control over the brewing process. For more information on specific equipment and how they fit into a brewing setup, visit our [product page](https://skeequipment.com/products).

The Beer Brewing Process Automated

The traditional beer brewing process involves several stages, including mashing, boiling, fermenting, conditioning, and packaging. With automated beer brewing, each of these stages can be monitored and controlled using automated systems. For instance, in the mashing stage, the temperature and timing can be precisely managed, contributing to the perfect extraction of sugars from the malt.

During fermentation, monitoring yeast activity and adjusting conditions can be done remotely, ensuring optimal growth. The final stages of conditioning and packaging can also benefit from automation, streamlining workflow and ensuring that the product is efficiently processed for distribution. Explore our content on [brewing techniques](https://skeequipment.com/brewing-techniques) to learn more about how these processes interact.

The Future of Automated Beer Brewing

The future of automated beer brewing holds exciting prospects, with advancements in artificial intelligence and machine learning set to further enhance brewing efficiency. Predictive analytics could revolutionize how brewers optimize their ingredients and brewing conditions, potentially elevating the quality of craft beer to new heights. Customization and personalization of flavors may also become more prevalent, attracting a broader consumer base.

Brewery owners considering these advancements should stay informed about the latest industry trends. SKE Equipment continuously updates our offerings to ensure you’re equipped with the latest technology. Make sure to follow us for more updates and insights on brewing innovations.

Frequently Asked Questions

What is automated beer brewing?

Automated beer brewing refers to the use of technology to control and monitor the brewing process, enhancing efficiency and consistency in beer production.

What are the benefits of automation in brewing?

The key benefits include increased production efficiency, consistency in flavor, reduced labor costs, and enhanced quality control.

Can automated systems be used in home brewing?

Yes, many automated systems are available for home brewers, allowing for easier management of the brewing process while still being able to experiment with different recipes.

Contact Us

If you have more questions about automated beer brewing or would like to discuss solutions for your brewery, feel free to reach out:

- Facebook: Follow us on Facebook

- Email: info@skeequipment.com

- Contact us via the form at the bottom of the page.

“