”

Introduction

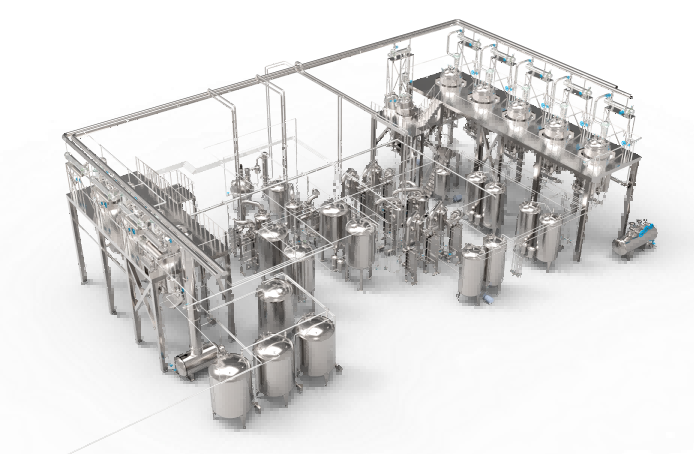

Beer fermentation tanks are essential components in the brewing process, specifically designed to facilitate the fermentation of beer. These tanks are vital for controlling the fermentation environment, ensuring consistent product quality, and optimizing the brewing schedule. At SKE, we specialize in providing high-quality beer fermentation tanks tailored for breweries of all sizes. Understanding the various types, benefits, and maintenance of these tanks is crucial for brewers who aspire to maintain high standards in their craft.

Types of Beer Fermentation Tanks

There are several types of beer fermentation tanks utilized in the brewing industry, each serving distinct needs. The most common types include:

- Open Fermentation Tanks: These tanks allow for natural fermentation processes and are often used for traditional brewing styles. Open tanks are typically stainless steel and allow for easy monitoring.

- Closed Fermentation Tanks: These are designed to limit oxygen exposure, making them ideal for lagers and producing cleaner beers. Closed systems are often equipped with pressure controls.

- Conical Fermentation Tanks: Known for their cone-shaped bottom, these tanks are excellent for yeast collection and are commonly used in both commercial and home brewing settings. SKE’s advanced conical fermentation tanks are engineered for optimal yeast management.

Understanding the differences between these types can help brewers choose the right fermentation tank for their processes. For a deeper dive into the specifics of fermentation technologies, please check our detailed guide.

Benefits of Using Beer Fermentation Tanks

The use of specialized beer fermentation tanks offers several advantages over traditional fermentation methods:

- Controlled Environment: Beer fermentation tanks provide a controlled environment that maintains optimal temperatures and reduces the risk of contamination.

- Efficiency: These tanks allow for quicker fermentation cycles, enabling breweries to produce larger volumes of beer in shorter timeframes.

- Quality Consistency: By using fermentation tanks, brewers can ensure a consistent taste and quality in their products regardless of batch size.

These benefits empower brewers to enhance their production processes. For a closer look at how to elevate your brewing operations, explore our resources on scaling breweries.

Maintenance of Fermentation Tanks

Proper maintenance of beer fermentation tanks is crucial for ensuring longevity and optimal performance:

- Regular Cleaning: Sanitation is key. Regularly cleaning and sanitizing tanks helps prevent off-flavors and contamination.

- Temperature Monitoring: Consistently checking temperature controls can help maintain the right fermentation conditions.

- Inspection for Leaks: Regular inspections for signs of leaks or damage will help maintain the integrity of the tanks and the quality of the beer.

A well-maintained beer fermentation tank contributes significantly to the brewing quality. Our maintenance guides provide valuable insights on preserving the life of your equipment.

Conclusion

Beer fermentation tanks are pivotal in the brewing process, offering efficiencies, consistency, and quality control. By understanding the different types and maintenance requirements of these tanks, breweries can better prepare themselves for growth and excellence. SKE is committed to supporting your brewing journey through top-notch equipment and resources. Explore our selection of fermentation tanks to find the perfect match for your brewing needs.

Frequently Asked Questions

What is a beer fermentation tank?

A beer fermentation tank is a specialized container used in brewing to facilitate the fermentation process of beer, where yeast converts sugars into alcohol and carbon dioxide.

How does a conical fermentation tank work?

A conical fermentation tank allows yeast to settle at the bottom after fermentation, making it easier for brewers to harvest yeast for future batches while simplifying cleaning processes.

What is the ideal temperature range for fermentation?

The ideal temperature range for fermentation varies based on the beer type but typically falls between 65°F to 75°F (18°C to 24°C) for ales and 45°F to 55°F (7°C to 13°C) for lagers.

Get in Touch

If you have any questions about our beer fermentation tanks or need assistance with your brewing equipment, don’t hesitate to reach out!

Follow us on Facebook: SKE Facebook Page

Email us at: info@skeequipment.com

Please fill out the form at the bottom of this page to get started!

“