”

What is Automated Brewery Equipment?

Automated brewery equipment refers to advanced systems and machinery designed to streamline and enhance the brewing process in breweries. These systems reduce the need for manual intervention and improve operational efficiencies. By utilizing the latest technology, automated equipment can help breweries maintain consistent quality while minimizing labor costs. Companies like SKE Equipment offer state-of-the-art solutions that integrate seamlessly into existing setups, allowing breweries of all sizes to optimize their production capabilities.

Benefits of Automation

Implementing automated brewery equipment yields numerous benefits, including:

- Increased Efficiency: Automation streamlines processes, reducing the time and resources necessary for brewing.

- Consistency and Quality Control: Automated systems ensure that each brewing batch meets the same high standards, contributing to superior product quality.

- Cost Savings: By reducing labor requirements and minimizing waste, breweries can substantially decrease operational costs.

For instance, breweries utilizing SKE’s automated solutions have reported significant improvements in both production speed and product consistency, allowing them to focus on crafting unique brews that stand out in the market.

Types of Automated Brewery Equipment

There are various types of automated brewery equipment designed for different stages of the brewing process:

1. Automated Brewhouses

Automated brewhouses offer complete control over the brewing process, including mashing, boiling, and fermentation. Such equipment is essential for any brewery aiming to scale. SKE’s automated brewhouses are designed for reliability and precision.

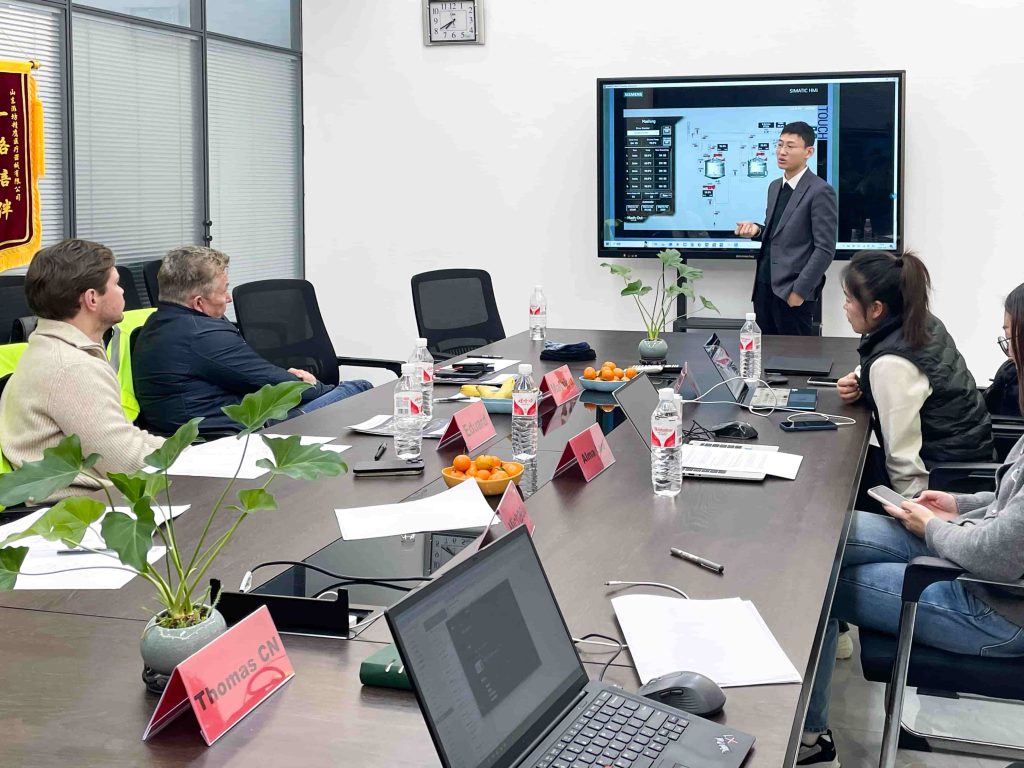

2. Control Systems

These systems help monitor various parameters such as temperature and pressure throughout the brewing process, allowing for real-time adjustments and ensuring optimal conditions. By integrating SKE control systems, brewers can ensure that every factor is precisely measured and controlled.

3. Bottling and Packaging Equipment

Automated bottling lines are crucial for scaling production, as they minimize manual handling and improve efficiency. These systems automate filling, capping, and labeling processes, making them essential for high-volume breweries looking to increase throughput.

Through SKE’s selection of automated bottling equipment, breweries can enhance their packaging efficiencies and focus on crafting their art.

Features to Consider in Automated Brewery Equipment

When looking for automated brewery equipment, it’s essential to consider several features that can impact your brewing operations:

- Scalability: Your system should grow with your brewery. The right equipment from SKE offers modular solutions for expansion.

- User-Friendly Interfaces: An intuitive interface ensures that your team can quickly adapt to automated systems.

- Reliability: Invest in equipment that delivers consistent performance and is backed by strong technical support, like that provided by SKE.

These features can provide long-lasting gains in productivity and quality, making your investment worthwhile.

Conclusion

Automated brewery equipment transforms brewing operations, driving efficiency while enhancing product quality. By choosing equipment designed by SKE, breweries can leverage cutting-edge technology to stay competitive in the evolving market. Moreover, understanding the different types and features of automated solutions is crucial for making informed decisions that align with your business goals.

Frequently Asked Questions

What is automated brewery equipment?

What are the benefits of automation in brewing?

What types of automated brewery equipment are available?

Get in Touch with SKE

Interested in upgrading your brewery with automated equipment? Connect with us!

Email: info@skeequipment.com

Fill out our contact form at the bottom of the page for more information and personalized assistance.

“