ABOUT SKE

SKE (Ningbo ShihKuang Engineering Equipment Limited) is one of the core subsidiary of SKE & EAGLE Group.

SKE was founded in 2000 and is among China’s earliest companies engaged in the production and manufacturing of craft brewery equipment.

Our journey began with the Ningbo Stainless Steel Equipment Facility – a specialized manufacturer of stainless-steel beverage equipment and mixing tanks .Through years of dedicated team efforts, SKE has now grown into a leading manufacturer of high-end brewery and beverage equipment, as well as processing equipment in the fluid-processing industry.

We are passionate about advancing processing technology, driving innovation, and upholding high standards in project management and services.

Our core philosophy centers on Quality, Engineering Innovation, and Superior Service.

Passion, Dedication, and Responsibility define SKE’s team culture.

Integrity, Openness, and Mutual Benefit form SKE’s corporate vision and values.

We are committed to pursuing shared growth and development with our partners.

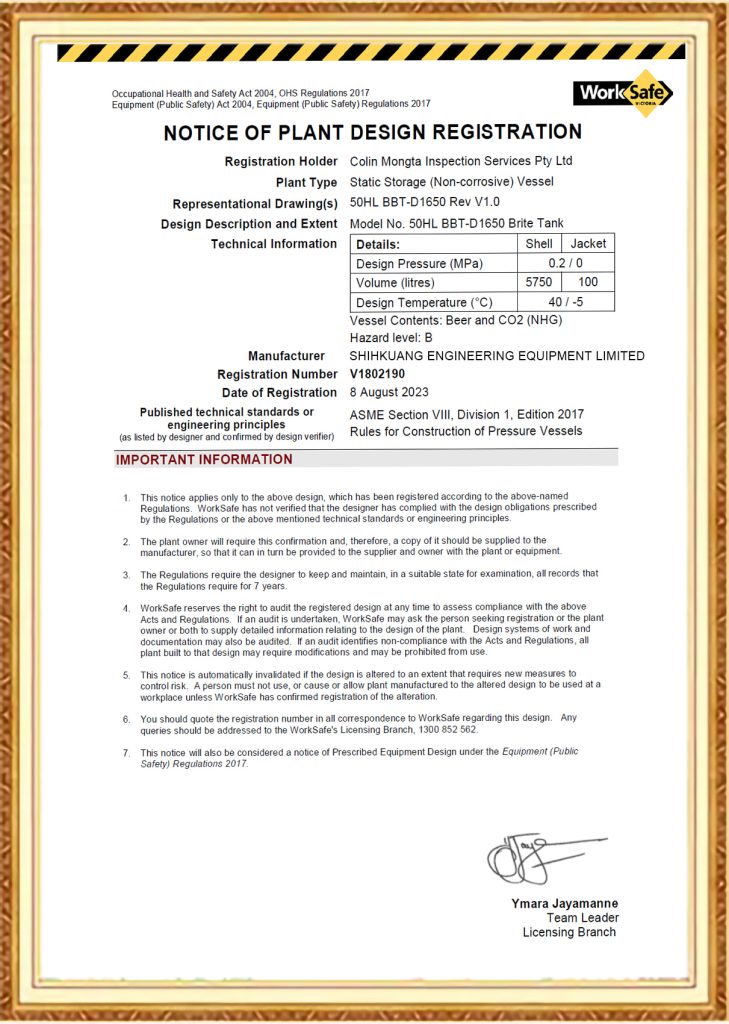

Our Certificates

SKE’s brewery ,beverage and processing facility solutions fully comply with all international standards.

This includes certifications for key components and systems, as follows:

- Pressure vessels (e.g., pressure tanks and cellar tanks)

- Complete products and electronic components (e.g., control systems)

SKE stainless steel vessels are engineered and manufactured in accordance with the ASME standard and can also be certified to meet PED and AS 1210 requirements.

In terms of electrical compliance, we adhere to the wiring standards of individual countries and have a thorough understanding of electronic component requirements to ensure successful inspections. Our products hold certifications such as UL, CUL, CE, and AS, guaranteeing safe operation worldwide

Engineering

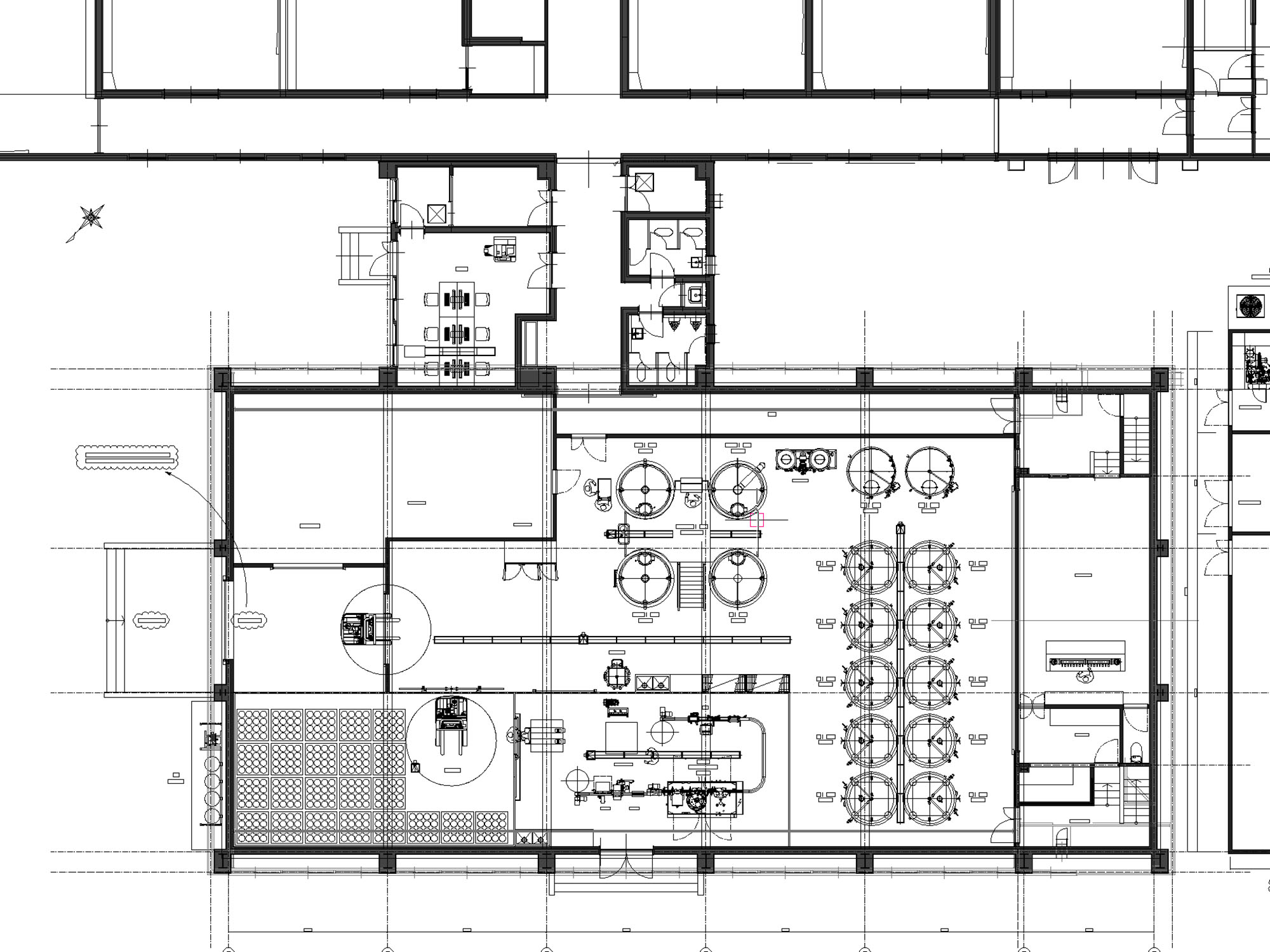

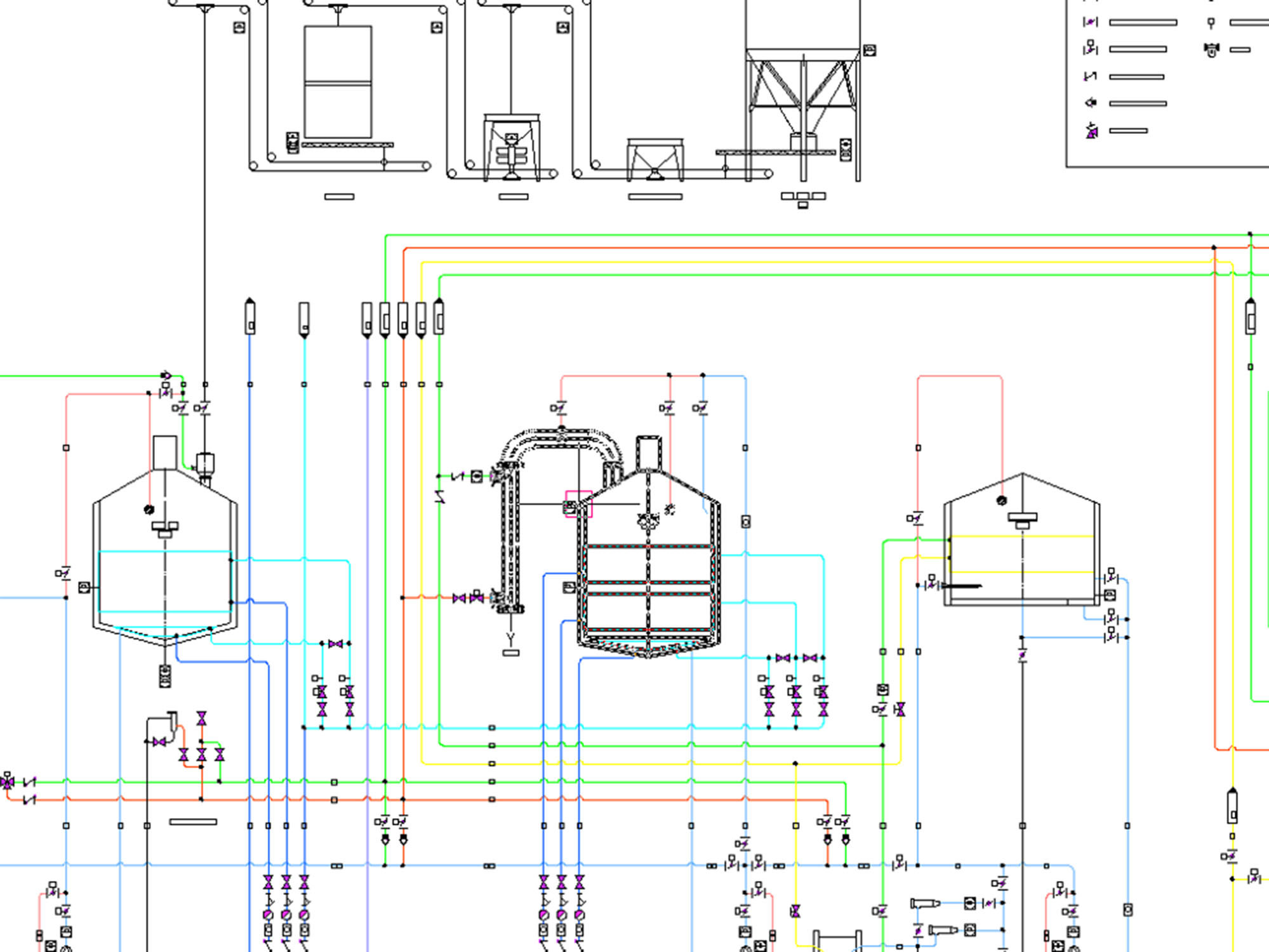

SKE’s engineers are like “magicians” — they turn concepts and plans into practical engineering drawings and programming.

Our engineering team possesses the following core skills and capabilities:

- Rich Experience of Brewing, Fermentation & Distilling Equipment

- Deep Knowledge of Liquid Processing

- Abundant Experience in Tanks & Process System Design

SKE’s engineering team excels at customizing and designing solutions based on system scale, on-site conditions, process requirements, and budget constraints.

At SKE, we believe engineering expertise is a core competitive advantage that sets us apart.

Our engineering team — consisting of mechanical engineers, electrical engineers, programming engineers, and drafters — is professional, passionate, diligent, and committed to continuous improvement.

Every project undergoes meticulous planning and is accompanied by comprehensive engineering documentation. This ensures customers have full visibility into the project timeline, materials used, and processes involved.

- P&ID Drawing

- Layout Drawings

- 2D Drawings

- 3D Render Drawings

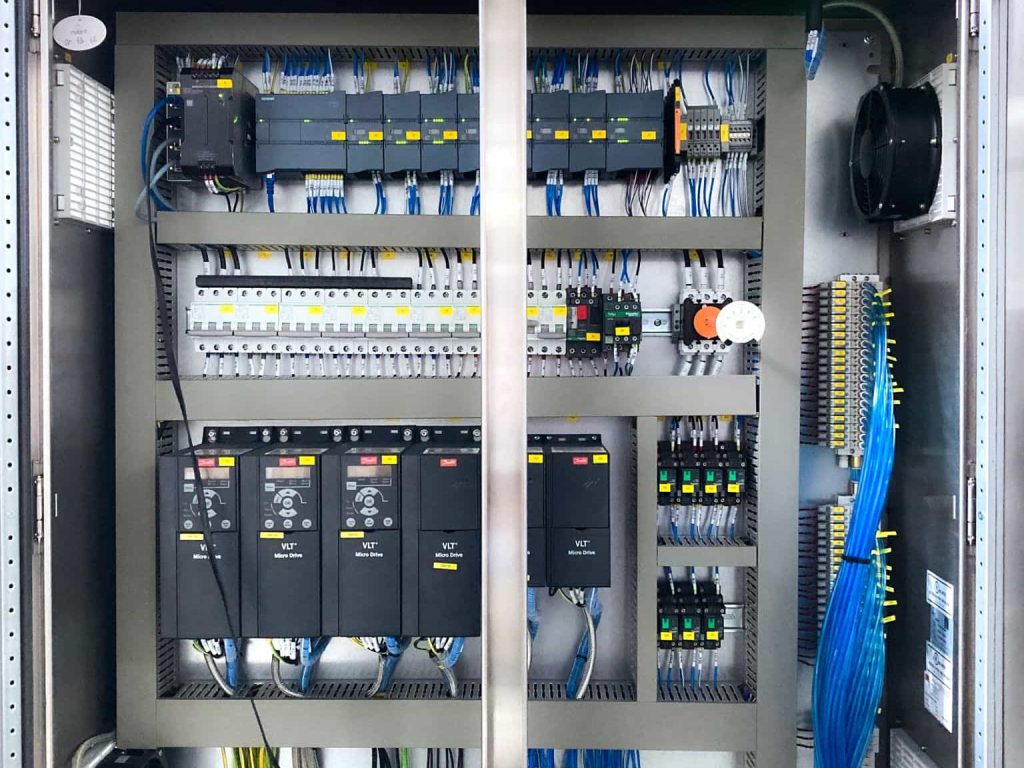

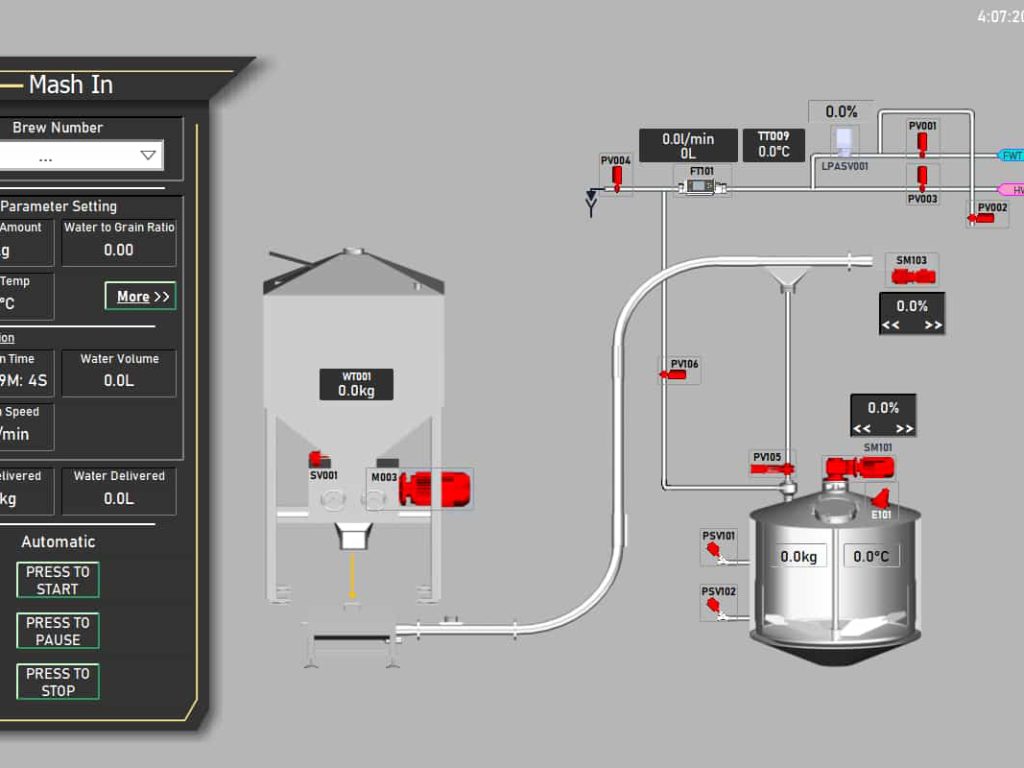

Automation

SKE prioritizes automation to simplify operations and boost efficiency.

We provide manual, semi-automatic, and fully automatic control systems in various specifications, tailored to meet diverse customer requirements.

Backed by years of engineering and technical expertise, our automation solutions cover a wide spectrum — from basic manual controls to fully automated systems with touchscreen HMI interfaces and remote access capabilities. We only adopt industrial-grade components of global quality, and all our enclosed industrial control panels are certified by CE, UL, and CUL.

SKE’s engineering team stays ahead of technological trends, maintaining passion for innovation through collaboration with global partners and top-tier experts. This cooperation equips us with in-depth industry knowledge and insights, enabling us to develop unique automation solutions that streamline every aspect of our customers’ customized processes.

The automation will come with:

- Wiring Schematic

- Programming System

- Instant Remote Programming Upgrading Remote Trouble-Shooting Service Operation Manual

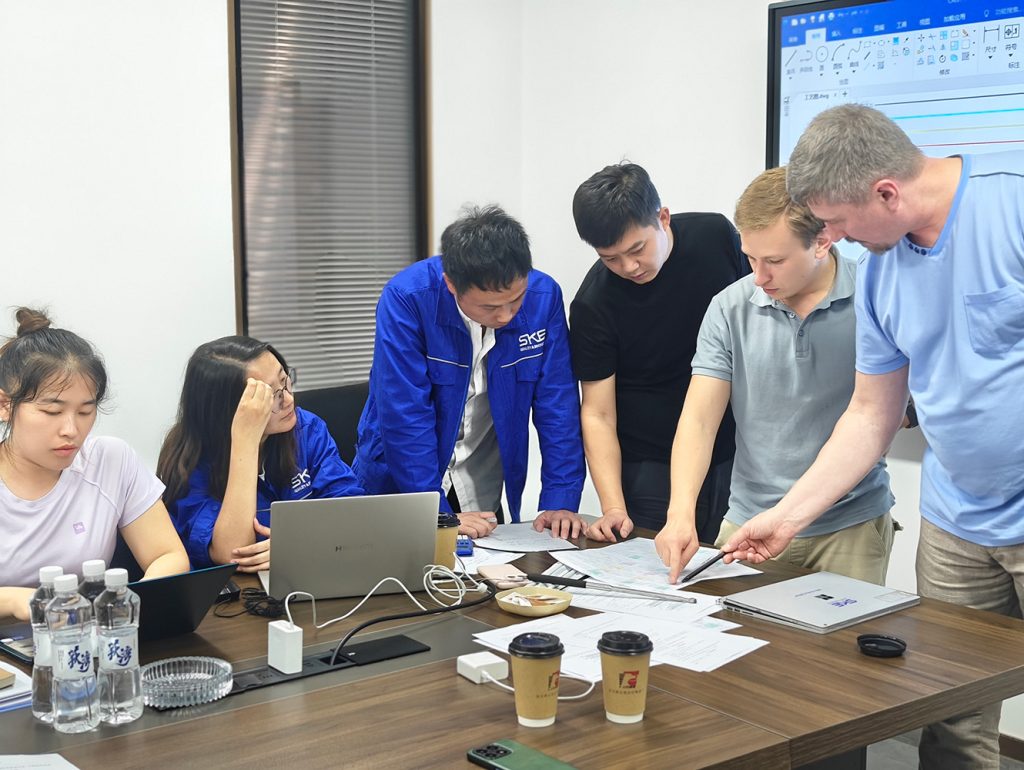

Project Management

SKE upholds a robust project management framework. Every project is assigned to an exclusive team, led by a project manager who takes full responsibility for supervision, coordination, and overall project outcomes.Guided by established project management principles, SKE guarantees the effective execution of each project.

Project managers are pivotal to success.

At SKE, we recognize this importance — our project managers are engaged at every stage, from initial design to final production.Their core capabilities include:

- Profound knowledge of equipment and manufacturing processes

- Fluent written and spoken English

- Strong engineering backgrounds enabling quick resolution of emerging issues

- Extensive project management experience

With hands-on expertise, SKE’s project managers offer full support to bring your ideas to life.

Premium Raw Materials

High-quality raw materials are essential to best-in-class quality control, and SKE prioritizes this at the very start.We select only the finest raw materials from well-established, reliable suppliers, ensuring no compromise on input quality.

All materials go through thorough examination, and we provide customers with a detailed quality report and official inspection certificate for full transparency.

Process QA / QC

Zero-tolerance policy for quality defects is our strongest commitment to clients. To ensure premium quality, we focus on four key areas:

- Safe production practices

- Strict raw material control

- In-process inspections

- Factory Acceptance Tests (FAT)

Process QA/QC is “obligatory “since SKE was established.. Meanwhile, advanced testing equipment is also indispensable.

Process inspection includes:

- Spectral Detection

- Roughness Testing

- Tank Pressure Test

- Pipe Leakage Test

- X-Ray Testing

- Surface Checking

- Overall Inspection

FAT Inspection

Factory Acceptance Test (FAT) is a crucial process to ensure equipment meets performance standards before leaving the factory and to prevent on-site failures, directly determining the progress efficiency and cost control of subsequent projects.

The core value of FAT lies in “identifying and addressing issues before factory shipment”. It resolves equipment defects and functional deviations within the factory, rather than waiting until after on-site installation. Its importance is mainly reflected in three aspects:

- Reducing on-site risks and costs

- Ensuring equipment meets requirements

- Paving the way for on-site commissioning (SAT)

SKE places Factory Acceptance Test (FAT) as a top priority. During the FAT process, the project manager leads the entire project management team to conduct a comprehensive inspection in strict accordance with the equipment factory acceptance criteria. Meanwhile, the team simulates complex on-site operating conditions and performs equipment commissioning in line with the equipment debugging procedures, ensuring the equipment can truly achieve “plug-and-play” once it arrives at the site.

Craftman Team

The reason SKE products have gained global recognition lies primarily in two core pillars: a professional production team and rigorous manufacturing processes.

In terms of processes, SKE adheres strictly to the high-standard production norms of Ningbo City throughout the entire workflow, ensuring precise control over every production step.

In terms of the team, the production team not only possesses profound processing experience but also upholds a professional dedication to pursuing excellence.

We have always firmly believed that frontline workers are not only the cornerstone of SKE’s production operations but also the valuable asset driving the company’s sustainable development.

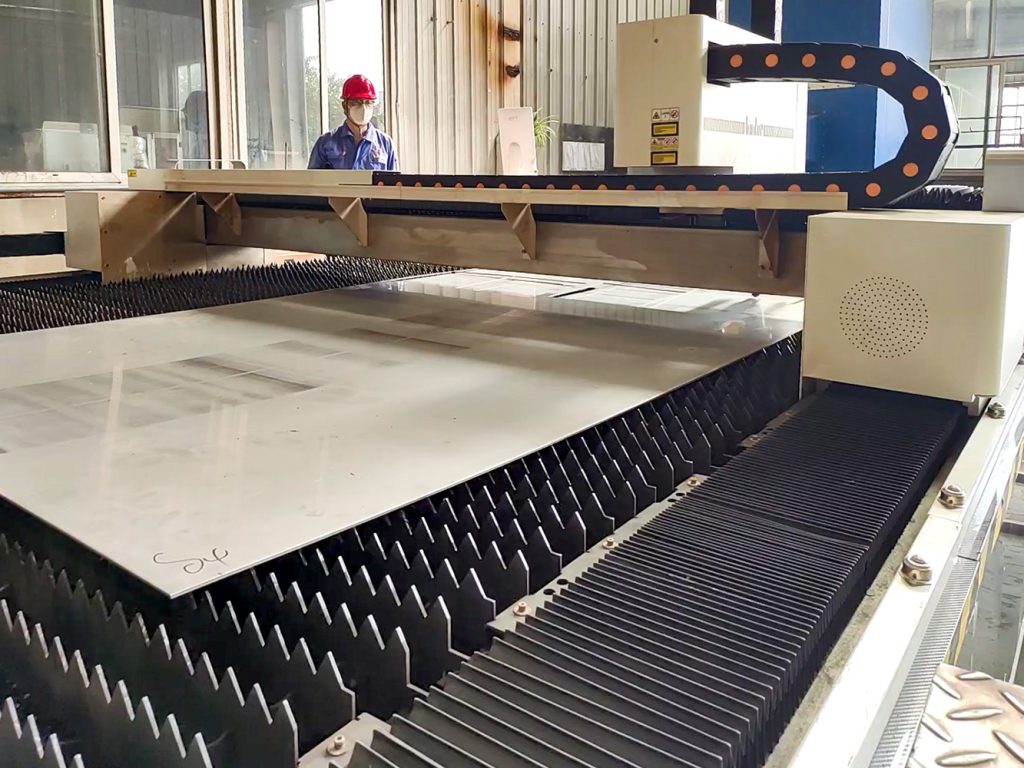

Auto Fabrication Equipment