What is a Pilot Brewing System?

A pilot brewing system is a compact brewing setup designed for small-scale brewing experiments and recipe development. It allows breweries, research facilities, and homebrewers to conduct trials and refine their methods without the investment required for full-scale production systems. The versatility of pilot systems makes them ideal for innovators looking to develop unique beer profiles or test brewing conditions.

Benefits of a Pilot Brewing System

Using a pilot brewing system offers numerous advantages. Firstly, it significantly reduces the cost and risk associated with brewing new recipes. By allowing for small batch sizes, brewers can experiment with different ingredients and techniques without committing extensive resources. Additionally, pilot systems provide a perfect environment for quality control, helping to ensure that each batch meets the desired standards.

With SKE’s pilot brewing systems, brewers enjoy enhanced precision and control, which is crucial for optimizing the brewing process. This enhances the quality of the final product and promotes innovation within the craft of brewing.

Key Components of a Pilot Brewing System

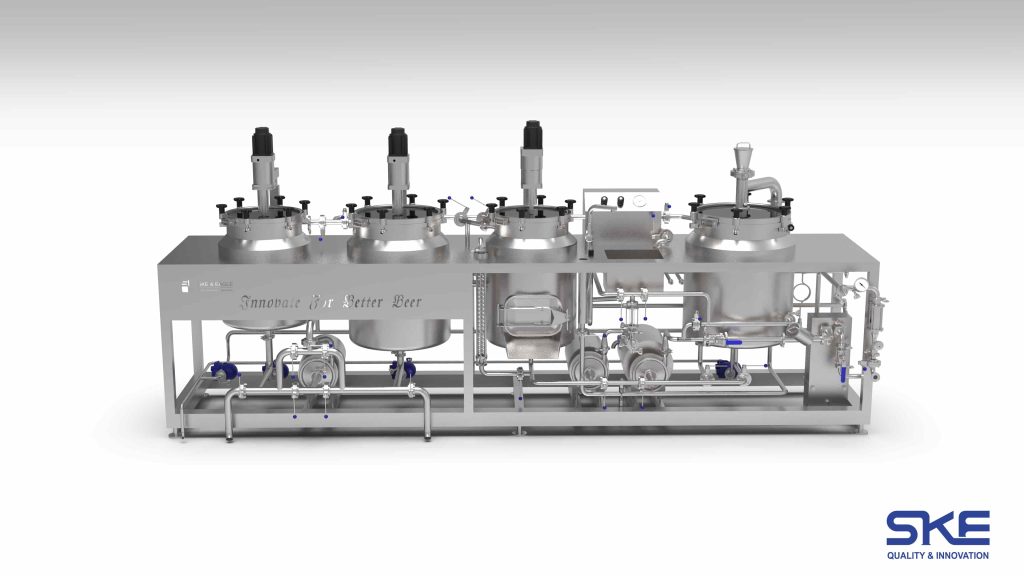

A typical pilot brewing system consists of essential components such as a mash tun, boil kettle, fermentation tanks, and cooling systems. Each component plays a critical role in the brewing process. The mash tun is where the grains are steeped in water to convert starches to sugars. The boil kettle is utilized for boiling the wort and adding hops, while fermentation tanks are where yeast is introduced to produce alcohol.

SKE provides various models tailored to different brewing styles and capacities, ensuring that brewers can find the perfect fit for their needs.

Choosing the Right Pilot Brewing System

When selecting a pilot brewing system, consider factors such as operational capacity, ease of use, and scalability. It’s crucial to choose a system that aligns with your brewing objectives and production goals. SKE’s offerings include various configurations, making it easier to find a solution that suits specific requirements. For detailed specifications and comparisons, check out our product catalog.

Why Choose SKE for Your Pilot Brewing Needs

At SKE, we understand the nuances of the brewing industry, and our pilot brewing systems are designed with the highest standards of quality and efficiency in mind. Our systems incorporate the latest technology, ensuring that brewers can achieve consistent results with every batch. Moreover, our customer support team is knowledgeable and ready to assist, providing guidance throughout your brewing journey.

For breweries looking to refine recipes and expand their product offerings, SKE’s pilot brewing systems are the ideal solution. Explore more about our systems by visiting our Pilot Brewing System page.

FAQ

What is the typical size of a pilot brewing system?

Pilot brewing systems usually have a capacity ranging from 1 to 10 barrels, allowing brewers to create small batches for testing new recipes.

Can I use a pilot brewing system for commercial brewing?

Yes, many commercial brewers use pilot brewing systems for experimenting with new recipes and techniques before scaling up production to full-size systems.

How does SKE support customers with their pilot brewing systems?

SKE offers comprehensive customer support, including setup assistance, technical guidance, and maintenance tips to ensure optimal performance of your pilot brewing system.

Interested in Our Pilot Brewing Systems?

Connect with us to learn more about our products and how they can enhance your brewing experience:

- Facebook: SKE on Facebook

- Email: info@skeequipment.com

Feel free to fill out the contact form at the bottom of this page for more information!