SKE High Quality Distilling System

Distillery Equipment-Pot Still

SKE distillation equipment fittingly enough inside the pot. The pot is the large tub-like base that the rest of the components of the still attach themselves to. This is where the liquid to be distilled starts its transformative journey. The pot may be heated through a variety of means. This includes a steam jacket lining the outside walls of the pot or even a steam coil inside the pot itself, the heating method (steam heating or electric heating) can be customized.

The pot sill usually comes with inner copper materials with stainless steel cladding. Equip with Explosion-proof motor & gear box, agitator, glass manway, spray balls, temperature gauges, safety valve and pressure gauge, pressure relief valve, steam/oil/inlet and outlet, manual valves, etc.

Distillery stills

SKE distillation equipment is an essential item used in the distillation of liquid mixtures to separate the mixture into its component parts, or fractions, based on the differences in volatilities. The purpose of a distillation column is to separate a compound containing two or more mutually soluble solutions by their variation of individual boiling points.

The vapor comes into contact with the bubble caps inside the column; causing vapor to condense back into a liquid. The liquid drips back down through the column and is eventually forced back up through the caps and plates, each plate with red copper bubble caps and one sight glass, a CIP ball, a discharge valve, etc. The number of the plates in the column will directly determine the alcohol content of the target spirit got finally.

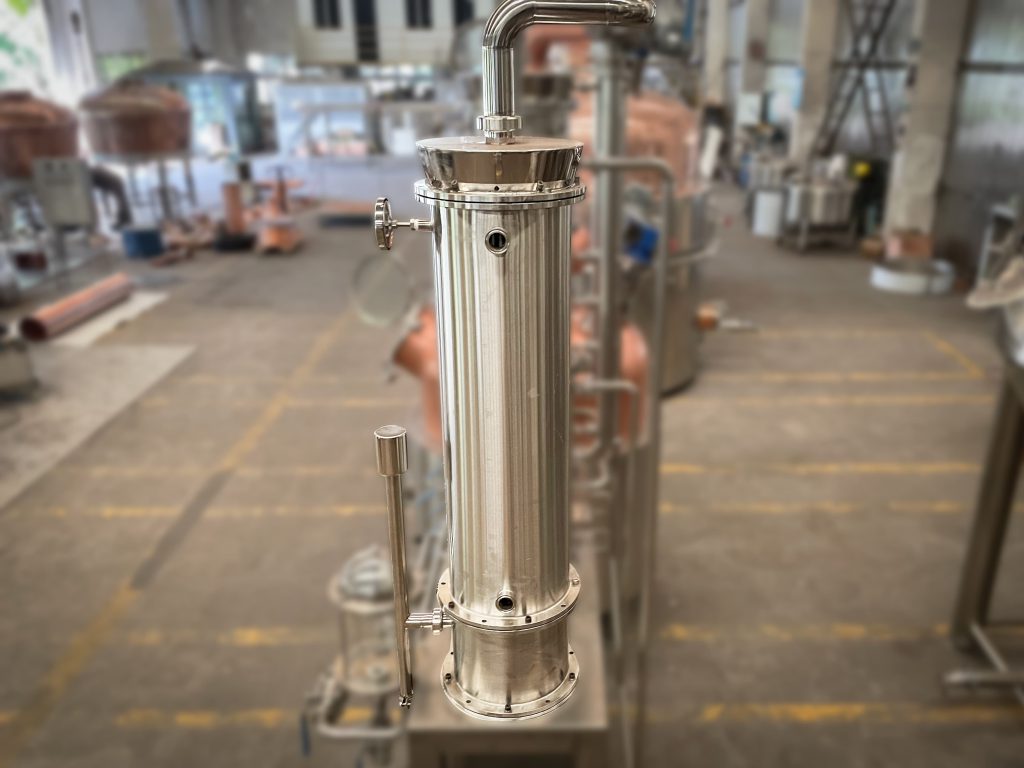

Distillery Equipment Dephlegmator

Distillation equipment dephlegmator is a device arranged for the partial condensation of a multicomponent vapor stream. The vapor stream flows vertically upwards and the condensate (condensed vapor) runs back down under the influence of gravity.

Tube type heat exchanger dephlegmator at top of the distillation column that sends distillate back toward the pot still, with a cooling water inlet and outlet, top with a thermowell or temp sensor for the temp probe. The cooling water inlet usually comes with a pneumatic or manual PID modulating valve to achieve the function of the temp automatic or manual controlled of the dephlegmator.

Gin Basket

Distillation Equipment the hot vapor enters the downpipe from above, exits from the bottom of the downpipe, rises upward, passing through the tray of botanicals, and exits through a horizontal tube at the top.

The gin basket allows for botanicals to be used in the vapor path added for a very clean and high-tier end product.

Condenser

This is a device or unit used to condense vapor into liquid, with a cooling water inlet and outlet, top with a thermowell or temp sensor for the temp probe. The cooling water inlet usually comes with a pneumatic or manual angle seat valve to achieve the function of the temp automatic or manual controlled of the condenser.

Spirit Parrot

SKE spirit parrot is connected between the condenser and spirit storage tanks, allowing the distillate to flow through on its way to the spirit storage tanks. It’s handy because the parrot will hold your alcoholmeter, so you can take real-time readings of the alcohol percentage during the distillation process.

Support Frame and Storage Tank

It usually comes with column support, no other functions. If you want to support more functions, the tanks type support can be customized, which will be put at the bottom of the column and condenser as the spirit storage tanks, there will be usually three storage tanks for the head spirit, heart spirit, and tail spirit.

Distillation System

- Running agitator on/off

- Tank light on/off

- Still temp display and auto control

- Dephlegmator temp display temperature auto control

- Condenser temp display temperature auto control

- Column temp display

- Emergency Stop Button