Flash Pasteurizer

SKE flash pasteurizer is specifically engineered for craft breweries and the beverage industry, catering to beer, soda, seltzer, RTDs (ready-to-drink beverages) and other carbonated drinks.

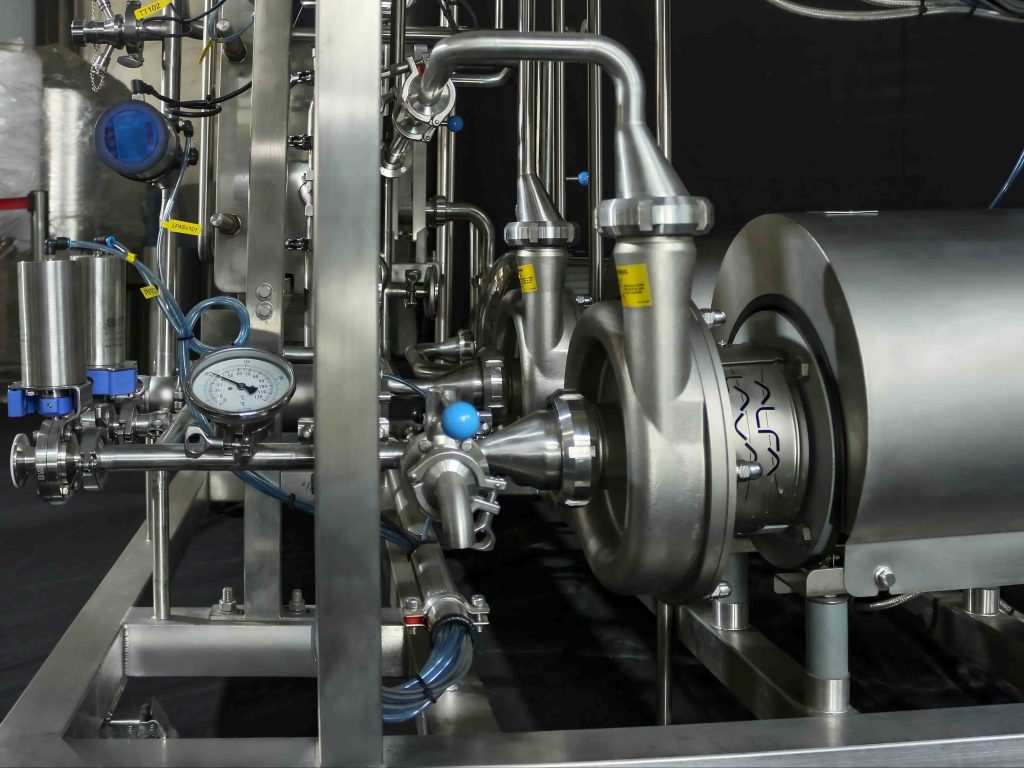

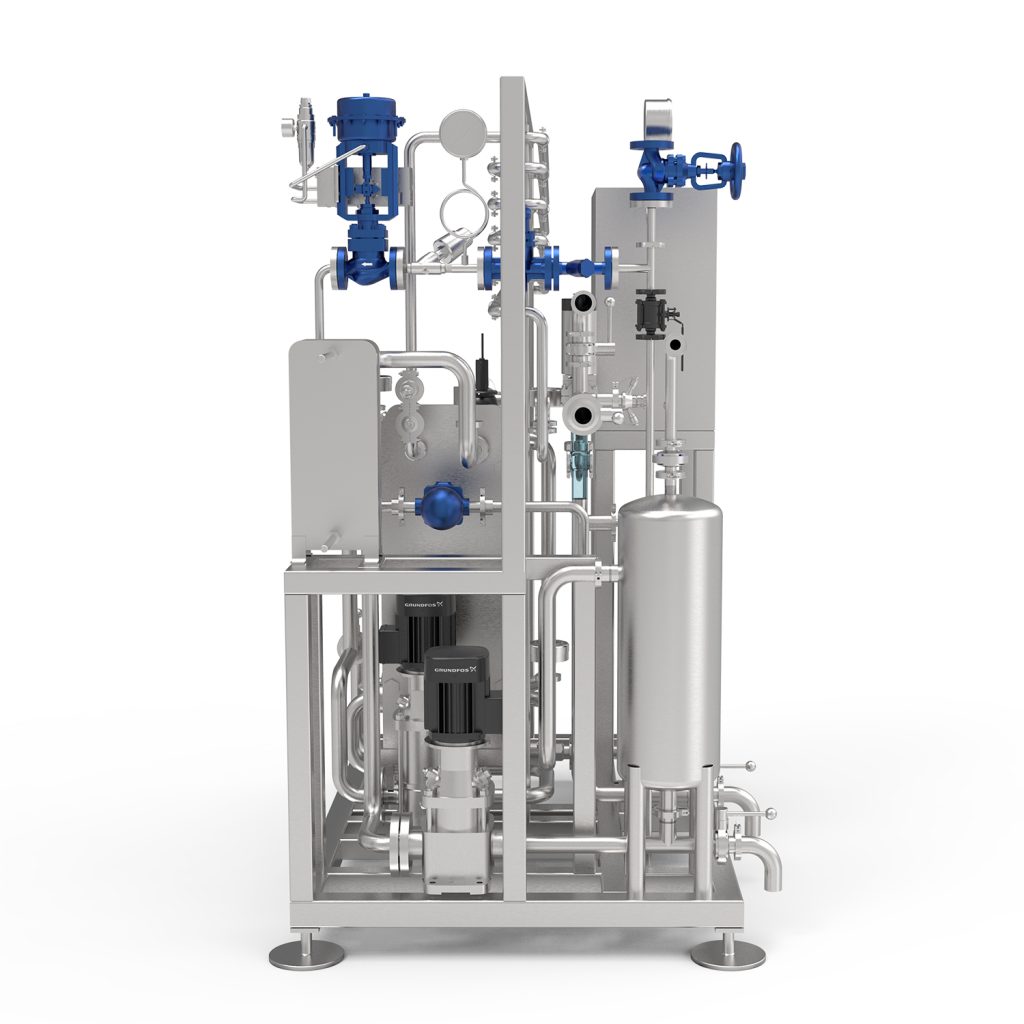

Its upgraded design features hard piping configurations for enhanced hygiene, along with a more compact skid structure. By adopting a cascade control loop, it improves temperature control accuracy and minimizes deviations caused by material agitation. The highly flexible programming enables curve recording, data output and batch settings, facilitating seamless production data tracking.

Features

- Free Precise pasteurization unit (PU) setting and auto control, compatible with variable flow rates and temperature adjustment.

- PHX & loop design helps saving the energy up to 85-90% above, Relief the load of heating /cooling both sides.

- Excellent CIP compatibility and hygienic design; the sanitary, compact module ensures low maintenance requirements.

- High degree of automation and stable operational performance.

- Hygienic pipeline design to reduce the dead leg maximum, Capable to self-drain off.

- Automated Cascade control loop guarantees the smooth & gentle process and manage the deviation in max level.

- Friendly User interface for accessing the process control with flexible pasteurization range.

- Compact Skid design with small footprint. Plug & Play Installation.

Process

- Cold beer is boosting pump and enters the second zone (preheating section) of PHX, where it undergoes convective heat exchange with the 72+℃beer that was sterilized and heated, thus being preheated to 62℃+.

- The 62+℃ preheated beer flows out of 2nd zone and boosting up again before entering third zone (heating zone), where it is heated to the sterilization of 72℃ required by automated regulating the medium temp. Then comes in holding pipe and maintain it at this temperature for 30 seconds to sterilize the bacteria.

- After sterilization, the 72+℃ beer returns to 2nd zone of the PHX, heat conducts to the 4℃ cold beer, which is cooled to 17 ℃. It then enters 1st zone of PHX and is cooled to 4℃ by the -1℃ glycol water, Process entire under supervision and sterilization temp / pressure defeat will trigger the alarm and come into circulation loop.