”

What is an All In One Brewing System?

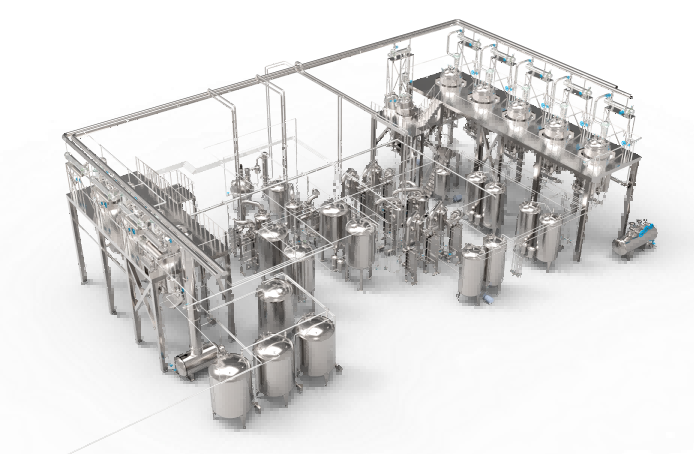

An all in one all grain brewing system is designed to streamline the brewing process, providing homebrewers with the efficiency and convenience needed to create high-quality beer. These systems often combine the functionalities of several traditional brewing pieces of equipment, making them compact and user-friendly. For enthusiasts looking to replicate the brewery experience at home, SKE’s all in one brewing systems provide excellent options that cater to various needs and skill levels.

The integration of technology in SKE products ensures that brewing becomes an enjoyable and less cumbersome task. From temperature control to automated processes, these systems allow for precise brewing, resulting in consistent quality from batch to batch. You can explore our brewing technologies to see how our products can make your brewing journey seamless.

Benefits of an All Grain Brewing System

One of the key advantages of using an all grain brewing system is the control it grants over the brewing process. Homebrewers can experiment with various ingredients and brewing techniques, yielding unique flavors and styles. SKE equips everyone from novices to seasoned brewers with high-quality systems that encourage creativity and exploration in brewing.

In contrast to extract brewing, an all grain system preserves the essential enzymes required for converting starches into fermentable sugars, leading to superior flavor profiles. The use of our advanced grain systems can further enhance your brewing experience, empowering you to create craft beers that rival those of local brewpubs.

How Does an All Grain Brewing System Work?

The functioning of an all in one all grain brewing system revolves around several core processes: mashing, boiling, and fermenting. Typically, the system allows brewers to mash directly in one vessel, eliminating the need for multiple equipment. This not only saves time but also minimizes cleanup, making brewing more accessible. SKE’s all in one brewing systems integrate these steps into a cohesive experience, ensuring that every brewer can achieve great results with less hassle.

After mashing, the wort is boiled and hops are added for flavor. The precision temperature control features in SKE systems ensure optimal extraction of flavors during this critical phase. Once boiled, the wort is cooled rapidly and transferred to a fermentation vessel, where yeast converts sugars into alcohol.

Choosing the Right System

When selecting the right all in one all grain brewing system, consider factors such as batch size, functionality, and ease of use. SKE offers a variety of systems tailored to different brewing capacities and user preferences. Whether you’re brewing small experimental batches or larger quantities for events, you’ll find a suitable option within our product range.

For comprehensive guidance on choosing the right brewing equipment, we recommend checking out our detailed comparisons of all grain systems that highlight the features, pros, and cons of various models, helping you make an informed decision.

Maintaining Your Brewing System

Proper maintenance of an all in one all grain brewing system is essential for consistent brewing quality. Regular cleaning and sanitizing help avoid contamination, which can spoil batches. SKE provides comprehensive maintenance guidelines to ensure your brewing equipment remains in perfect working order.

Beyond cleaning, inspecting components such as heating elements and pumps helps maintain efficiency. Engage with our equipment care resources for tips on caring for your brewing system so you can brew great beer for years to come.

FAQ

What is the difference between an all grain brewing system and a partial mash?

An all grain brewing system allows you to use malted grains directly, whereas partial mash involves a combination of extracts and grains. All grain brewing provides more control over the brewing process and ultimately better flavor.

Is it difficult to use an all in one brewing system?

Not at all! SKE designs all in one brewing systems with user-friendliness in mind. With clear instructions and integrated technology, beginners can brew excellent beer easily.

How long does it take to brew with an all in one system?

The brewing process usually takes between 4 to 6 hours, depending on the recipe and the system. SKE’s all in one systems speed up some stages, including heating and mashing, making the process more efficient.

Stay Connected with SKE

Join our community and stay updated on the latest brewing tips, products, and promotions. Follow us on Facebook and drop us a message anytime!

Email: info@skeequipment.com

Please fill out the contact form at the bottom of the page for any inquiries!

“