”

Introduction

In the fast-paced world of beverage manufacturing, the automated bottling line has emerged as a game-changer. In a competitive market, efficiency and quality are paramount. An automated bottling line replaces manual processes, ensuring that beverages are filled, capped, and labeled with minimal human intervention, resulting in higher productivity and consistency.

At SKE Equipment, we understand the needs of modern manufacturing processes. Our focus is not just on selling equipment; we aim to provide solutions that enhance operational efficiency, ultimately contributing to your brand’s success.

Benefits of Automated Bottling Lines

The integration of an automated bottling line offers numerous advantages. First and foremost, it significantly increases the production speed. Traditional bottling methods can be painstakingly slow, oftentimes leading to operational bottlenecks. Automation streamlines the entire process, ensuring beverages are processed swiftly while maintaining tight quality standards.

Additionally, automated systems reduce labor costs. The initial investment in automated equipment might be higher, but the long-term savings due to reduced labor requirements can justify the cost. This allows your company to reallocate resources to other critical areas, such as marketing or product development.

Moreover, automated lines can reduce the risk of contamination, a vital aspect in beverage production. SKE Equipment’s automated solutions incorporate advanced technology, ensuring that each bottle is filled under hygienic conditions, thereby preserving product integrity.

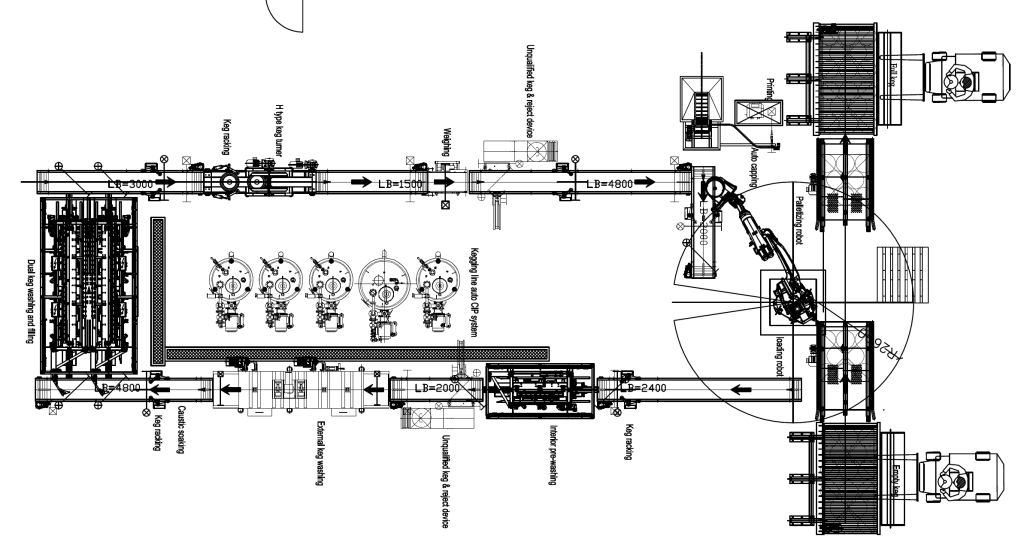

Key Components of an Automated Bottling Line

Understanding the components of an automated bottling line is essential for any manufacturer looking to enhance their production efficiencies. Core components include filling machines, capping machines, labeling machines, and conveyor systems. Each element plays an integral role in the bottling process.

For instance, SKE Equipment provides state-of-the-art filling machines that utilize precise measurement technology to ensure accurate fills. This is critical in maintaining not just compliance with regulations but also ensuring customer satisfaction with consistent product quantities.

An efficient conveyor system is equally important. It minimizes the time products spend idle, moving them smoothly from one process to another. By integrating an automated conveyor system from SKE, manufacturers can dramatically enhance throughput and operational efficiency.

Implementing an Automated Bottling Line

Successfully implementing an automated bottling line involves careful planning and execution. Understanding your production requirements is the first step. Manufacturers need to assess their production capacity, types of beverages, and any specific needs that tailor to their production line.

Furthermore, partnering with an experienced supplier like SKE Equipment can make a significant difference. Our team can guide you through the selection process, helping identify the best automated solutions that suit your specific needs, from design to maintenance.

Maintenance Tips for Your Automated Bottling Line

Maintenance is crucial to ensure the longevity of your automated bottling line. Regular checks on all machinery, including the filling and labeling systems, can prevent unexpected breakdowns that could disrupt production.

Additionally, SKE Equipment offers comprehensive maintenance packages designed not only to keep your equipment in top working condition but also to train your staff on best practices. Regular maintenance enhances efficiency and safety in the workplace.

Frequently Asked Questions

What is an automated bottling line?

An automated bottling line is a production setup where the processes of filling, capping, and labeling bottles are performed by machines with minimal human intervention, enhancing efficiency and quality control.

What are the benefits of using automation in bottling?

Benefits include increased production speed, reduced labor costs, improved product consistency, and enhanced safety and hygiene throughout the bottling process.

How do I choose the right automated bottling line?

You should assess your production needs, including capacity and product types, and consult with an experienced supplier like SKE Equipment to find solutions tailored to your specific requirements.

Contact Us

If you’re interested in learning more about our automated bottling line solutions, feel free to reach out to us!

- Facebook: Visit our page

- Email: info@skeequipment.com

- Fill out our contact form at the bottom for more information.

“