”

Introduction

Automated pallet conveyor systems are becoming essential in modern warehouses and manufacturing facilities. They streamline the movement of goods, improve flow efficiency, and significantly reduce the need for manual handling. By integrating these systems, businesses can enhance their operational workflows, minimize delays, and ultimately boost productivity. With the rise of e-commerce and high demand for quick turnarounds, investing in an automated pallet conveyor system is no longer optional but a necessity.

Benefits of Automated Pallet Conveyor Systems

Utilizing automated pallet conveyor systems offers numerous benefits crucial for maintaining a competitive edge in today’s market. Some of the key advantages include:

- Increased Efficiency: Automated systems handle the transportation of pallets seamlessly without the need for human labor, allowing for faster processing times.

- Reduced Labor Costs: With automation, businesses can significantly reduce labor costs by cutting down on manual tasks associated with pallet movement.

- Improved Safety: Reducing manual lifting and carrying minimizes workplace injuries, promoting a safer environment for employees.

- Enhanced Accuracy: Automated systems typically feature advanced technology that reduces human error in inventory management and order fulfillment.

For those ready to transform their warehouse operations, SKE’s automated pallet conveyor solutions offer a variety of options tailored to meet unique operational requirements.

SKE’s Automated Solutions

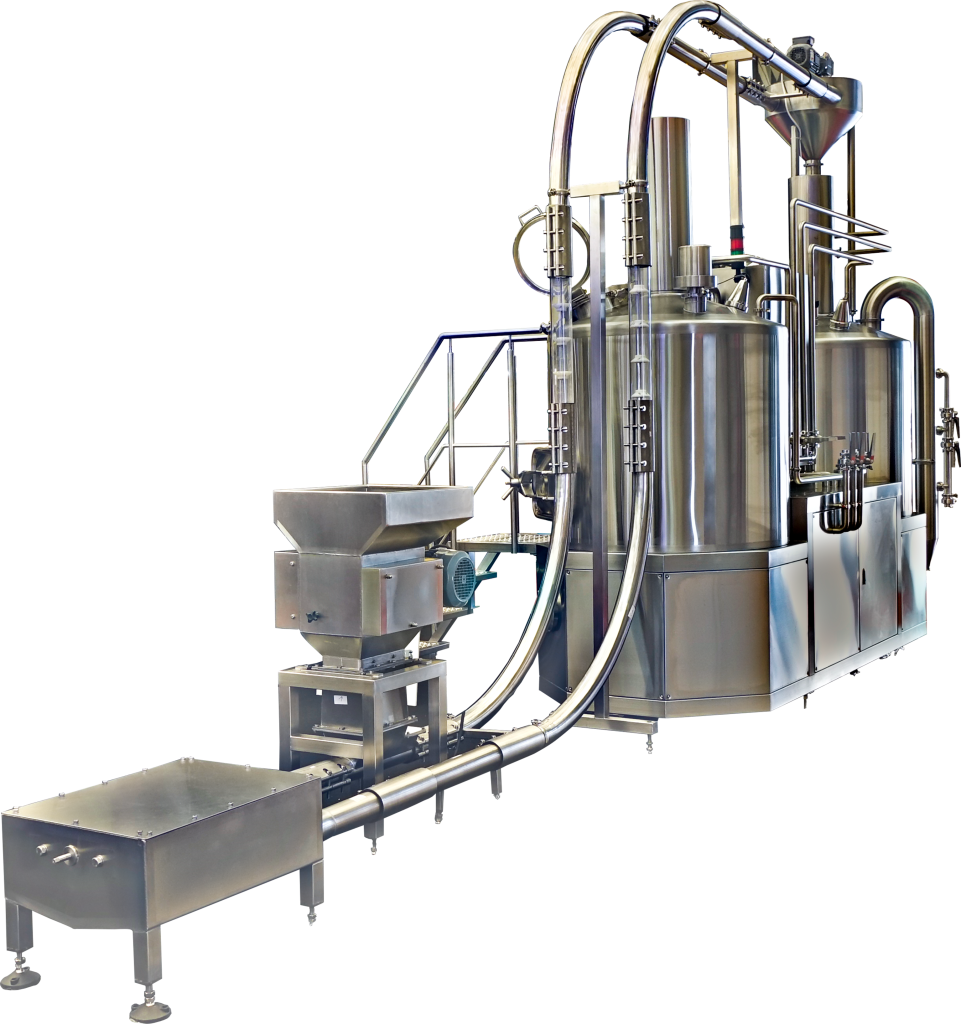

SKE specializes in providing top-notch automated pallet conveyor systems designed for diverse applications. Our systems are engineered with the latest technology to ensure unmatched reliability and durability. The range includes:

- Modular Pallet Conveyors: These systems are customizable to meet specific industry needs, allowing for flexibility in warehouse layouts.

- Heavy-Duty Pallet Systems: Ideal for industries dealing with heavy loads, providing robust performance and load-bearing capacity.

- Smart Conveyor Systems: Equipped with IoT capabilities, enabling real-time monitoring and seamless integration with existing warehouse management software.

For more information on our systems, visit our product page.

Applications of Automated Conveyor Systems

Automated pallet conveyor systems are versatile and can be employed across various industries including:

- Food and Beverage: Efficiently transport goods with minimal handling, adhering to strict hygiene standards.

- Pharmaceuticals: Ensure a controlled environment during transportation, which is critical for sensitive products.

- Retail: Streamline logistics in warehouses, especially for e-commerce and order fulfillment operations.

Leveraging SKE’s solutions can significantly enhance operational effectiveness, leading to improved workspace utilization and increased throughput.

FAQs

What are automated pallet conveyor systems?

Automated pallet conveyor systems are mechanized solutions designed to transport pallets throughout a facility without manual intervention, enhancing efficiency and safety.

What are the benefits of using automated conveyor systems?

Key benefits include increased efficiency, reduced labor costs, improved safety, and enhanced accuracy in operations.

How can SKE’s solutions improve my warehouse operations?

SKE’s automated solutions are designed with cutting-edge technology to enhance reliability, reduce operational costs, and effectively manage inventory, providing an overall boost to productivity.

Get in Touch

Interested in transforming your warehouse operations with automated pallet conveyor systems? Connect with us for personalized solutions tailored to your needs. Follow us on Facebook or reach out via email at info@skeequipment.com. You can also fill out the contact form at the bottom of this page to get started!

“