”

Introduction

The welding industry is undergoing a significant transformation with the advent of automated welding machines. These sophisticated machines are designed to enhance productivity and ensure high-quality welds, all while minimizing human error. As a leading provider of welding technologies, SKE is committed to delivering automated solutions that meet the evolving needs of manufacturers.

How Automated Welding Machines Work

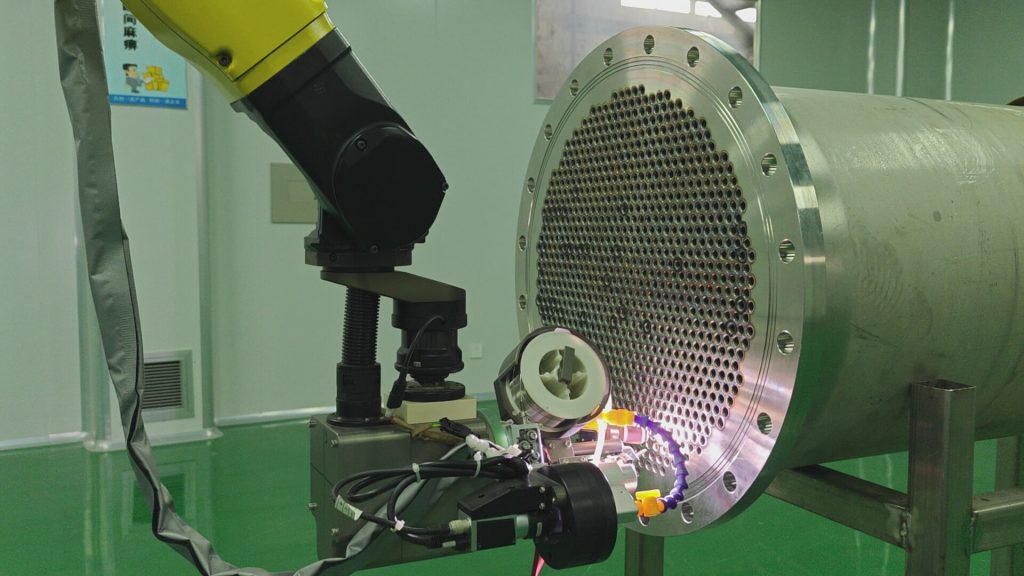

Automated welding machines function through a series of advanced technologies, including robotics and computer programming. The core of these machines is their ability to perform precise welding tasks with minimal human intervention. Equipped with sensors and advanced control systems, automated welding machines can adjust their parameters in real time based on the feedback received, ensuring optimal results every time.

Benefits of Automated Welding Machines

Utilizing an automated welding machine provides numerous advantages, such as increased efficiency, improved safety, and enhanced quality control. With automation, production rates can significantly increase while reducing the chances of defects. Moreover, machines such as those offered by SKE significantly lower the physical strain on human workers, leading to a safer working environment.

Additionally, these machines are equipped to handle complex welding tasks, making them ideal for industries that require high levels of precision. With SKE’s automated solutions, businesses can expect not only operational efficiency but also long-term cost savings.

Applications of Automated Welding Machines

Automated welding machines are employed across a variety of industries, including construction, automotive, aerospace, and manufacturing. In each of these sectors, they help achieve consistent results and meet rigorous industry standards. For example, in automotive manufacturing, automated welding is critical for assembling vehicle components swiftly and accurately.

SKE’s range of automated welding solutions has successfully catered to diverse applications, demonstrating versatility and reliability in production lines.

How to Choose the Right Automated Welding Machine

When selecting an automated welding machine, consider factors like the material type, the thickness of the material, and the complexity of the welds needed. SKE offers consultation services to help clients choose the machine that best suits their specific needs. Remember to evaluate the machine’s features, such as welding speed, precision, and ease of use, as these will greatly impact your productivity.

FAQ

What are the advantages of using an automated welding machine?

Automated welding machines offer increased productivity, better quality control, and reduced labor costs. They enhance safety by minimizing human involvement in hazardous welding tasks.

How much do automated welding machines cost?

The cost of automated welding machines varies based on their features, capabilities, and brand. SKE offers a range of options to fit different budgets without compromising on quality.

Can automated welding machines be used for different materials?

Yes, automated welding machines are versatile and can be used on various materials, including steel, aluminum, and composites, depending on the machine type.

Are there maintenance requirements for automated welding machines?

Yes, regular maintenance is essential to ensure optimal performance. This includes checking the calibration, cleaning and replacing parts as needed, and routine inspections.

“