Bag In Tank

SKE bag-in-tank are internationally recognized for superior quality. All SKE bag-in-tank are designed to ASME standards and come with PED and AS1210 certifications.

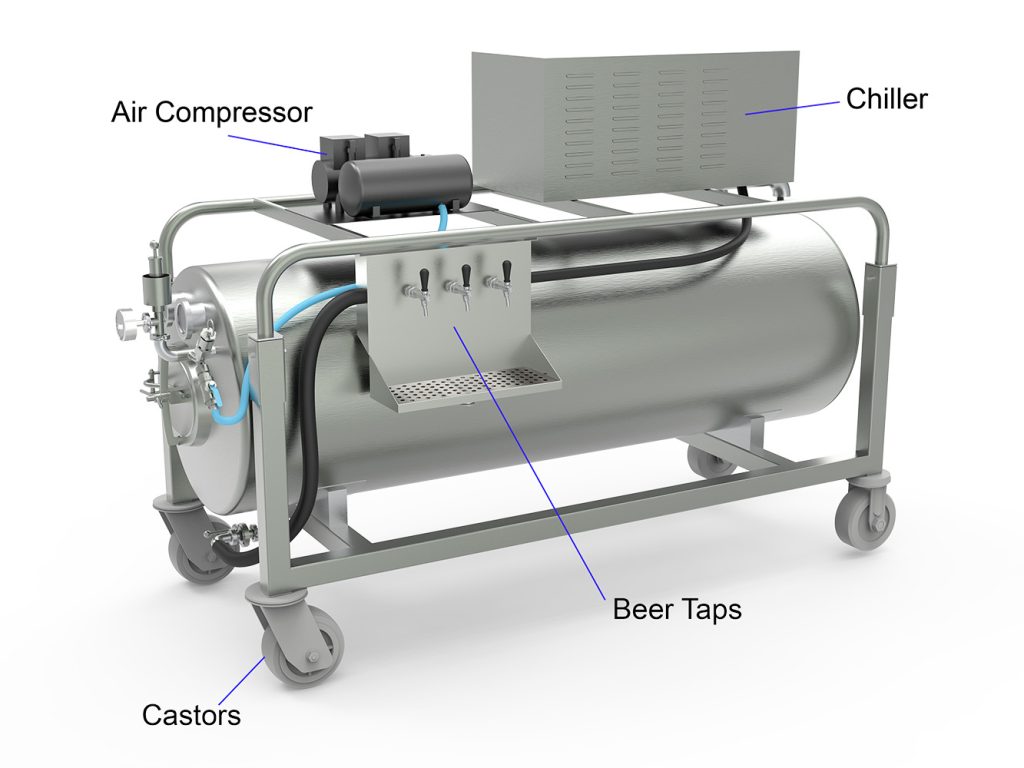

Steps for Changing To Event Tanks

- Lift down the tank which you want for event

- Install castors on flanges

- Install beer dispensing assembly

- Move to event

- Connect power supply

- Enjoy beer

Key Advantages

- Dispense beer with compressed air

- Save the cost on CO2

- No Tank CIP, just monthly water rinse

- Fast refilling, just replace the bag

- No need to keg beer, serve direct from tank

- Available in stainless steel or copper, are stackable and look amazing

- Can double as standard BBT/Serving Tank

- Automatic welding of dimple jackets for better cooling efficiency

- Castors are available as an option for easy moving

- Beer dispensing assembly as option for event

Specifications

- Bag-in-tank system with plastic bag liner

- Food grade SS304 construction

- Front manway

- 2 x sight glasses

- Pressure gauge

- Bung valve and PVRV Valves

- Cooling jacket around the cylinder

- CO2/compressed air connection

- Cooling water/glycol connection

- Independent temperature control

- Bottom beer outlet

- Four legs with adjustable feet

- PU foam insulation

- Internal shell: 2B, Ra≤0.6um; External Shell #4 finish

- Available pressure tank certificates of CE, PED for 2014/68/EU, AS1210 (Australia Standard)

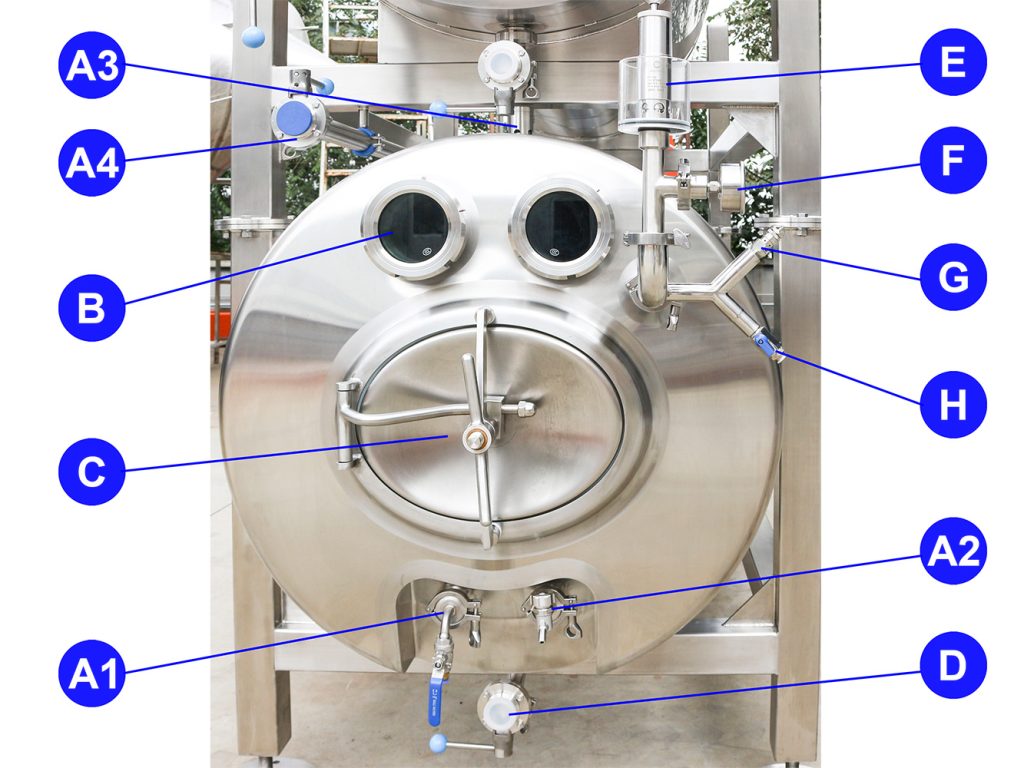

A——If act as a general bright tank or serving tank

A1——Carbon Stone

A2——Sample Valve

A3——PVRV

A4——CIP

B——Sight glass

C——Side manway

D——Beer outlet

E——Bunging valve

F——Pressure gauge

G——Exhaust valve

H——CO2/compressed air inlet