”

Introduction

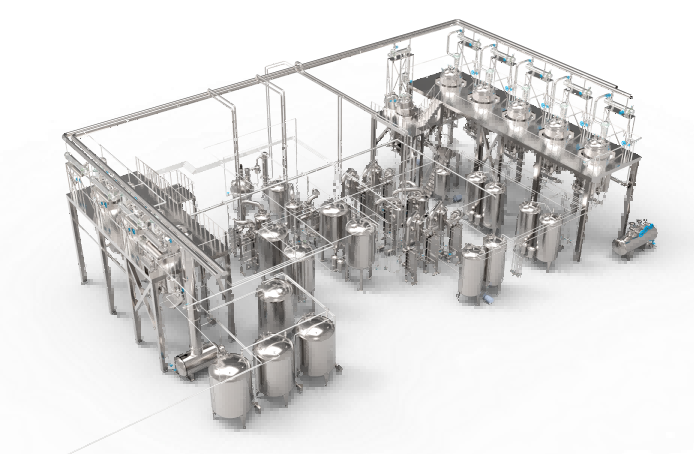

Understanding the essential pieces of beer distillery equipment is vital for any brewing operation. Whether you’re a budding craft brewer or an established distillery owner, investing in the right equipment can significantly affect the quality of your beer and the efficiency of your process. Not only does premium distillery equipment improve production consistency, but it also enhances the flavors and aromas of the final product.

SKE Equipment specializes in high-performance brewing and distillery solutions tailored to meet the needs of modern breweries. Our products are designed to facilitate not only better brewing outcomes but also improved operational efficiency.

Types of Beer Distillery Equipment

Beer distillery equipment encompasses a wide range of tools and machines that assist in the brewing process. Some of the most common types include:

- Brewing Vessels: These are where the magic happens—brewing tanks that allow for fermentation and conditioning.

- Heat Exchangers: Essential for managing temperature during the brewing process, aiding in pasteurization and cooling.

- Bottling and Packaging Machinery: Equipment that ensures your beer reaches customers in flawless condition.

At SKE, we provide an extensive range of high-quality beer distillery equipment designed to enhance your production capabilities.

Essential Features to Consider

When selecting beer distillery equipment, it’s essential to consider several key features that will impact your brewing process:

- Material Quality: Stainless steel is preferred for its durability and sanitary properties.

- Capacity: Determine the scale of your operation to choose the appropriately sized equipment.

- Automation: Modern breweries often benefit from automated equipment that simplifies the brewing process.

Implementing the right features can make a significant difference in efficiency. SKE offers equipment that is designed with these factors in mind, ensuring you receive high-performing tools for your brewery.

Maintaining Your Equipment

Proper maintenance of your beer distillery equipment is crucial for long-term success. Regular cleaning and inspections help to ensure that your equipment continues to produce high-quality beer:

- Regular Cleaning: Schedule routine cleanings to prevent contamination and residues.

- Inspections: Conduct inspections to identify wear and tear before they become major issues.

- Repairs: Address any mechanical issues promptly to maintain efficiency.

At SKE, we provide not only equipment but also guidance on maintaining your distillery tools to ensure optimal operation throughout their lifespan.

Choosing the Right Supplier

When investing in beer distillery equipment, choosing the right supplier is crucial. Look for a provider that offers a range of equipment, strong customer support, and a proven track record:

- Reputation: Research customer reviews and case studies to gauge reliability.

- Support: Ensure the supplier offers comprehensive support, including troubleshooting and repairs.

- Customization: Some breweries may benefit from custom solutions tailored to their specific needs.

SKE has established itself as a trusted supplier in the beer distillery market, offering quality products along with excellent customer support. You can visit our About Us page for further information on our services.

FAQ

What is essential beer distillery equipment?

Essential equipment includes brewing vessels, heat exchangers, and bottling machinery, which collectively facilitate the entire brewing process.

How do I maintain my brewing equipment?

Proper maintenance includes regular cleaning, periodic inspections, and immediate repairs of any observed issues to ensure optimal performance.

How can I choose the right supplier for brewing equipment?

Look for a supplier with a strong reputation, customer reviews, reliable support services, and custom options to meet your specific needs.

“