SKE Brewhaus Pro

SKE Brewhouse Pro is designed for brewpub, nanobrewery and micro brewery.

Design philosophy

- Big Head Space

- Customized Deisgn

- Skid Design ,Plug and Play System

- Easy to Brew

- Higher Brewing Efficiency

- No Dead Leg

- Self-Cleaning/Caustic Brew Function

- High Safety Standard to Secure Brewer’s Safety

Parameter

- Material, stainless steel 304

- Size, from 2hl to 15hl

- Finish, 2B inside, Ra≤06,#4 external

- Varies Brewhouse Vessel Combination.

- Heating method: steam, electrical or direct-fire

- Manual or Semi-Auto Control

- Certification, CE or UL/CUL or AS Standard

- Kettle Souring and Whirlpool Hopping Function

- Top International Brands for All Sensors ,Motors and Electrical Components

- Top Domestic Brands for All Mechanical Parts

SKE Mash Lauter Tun (MLT)

SKE Mash Lauter Tun (MLT) is equipped with top/bottom mounted ABB/WEG motor.The raking knife speed can be adjusted via a variable frequency motor (VFD). A low speed is used in the initial filtration stage to prevent disturbance of the material bed, while medium to high speeds are adopted in the middle and later stages of filtration to break up caking.

SKE places great emphasis on the design of the raking knife’s cutting angle to avoid two issues: an overly sharp angle that tends to chop materials, and an overly blunt angle that fails to effectively break up the material bed. The number of raking knives is designed following the principle of “uniform coverage with no dead zones”. The installation height of the raking knives is 5-10 cm above the false bottom, which prevents scratches on the false bottom (and subsequent damage to filter holes) while ensuring the knives can penetrate the material bed to achieve full loosening of the mash.

Water-Mixing Station is integrated into mash-in system which can precisely regulate brewing water to the required volume and temperature.

The tank is fitted with a stainless steel milled false bottom at the bottom, boasting a net open ratio of over 18% to ensure optimal filtering efficiency. Multiple backflush devices are mounted at the tank bottom to thoroughly clean the false bottom and prevent clogging.

Two sight glasses are installed on the side of the SKE mash lauter tun for monitoring the differential pressure (DP) value in the grain bed, facilitating real-time tracking of the filtration status.

An emergency stop button is positioned near the side manway to provide double safety protection for brewers.

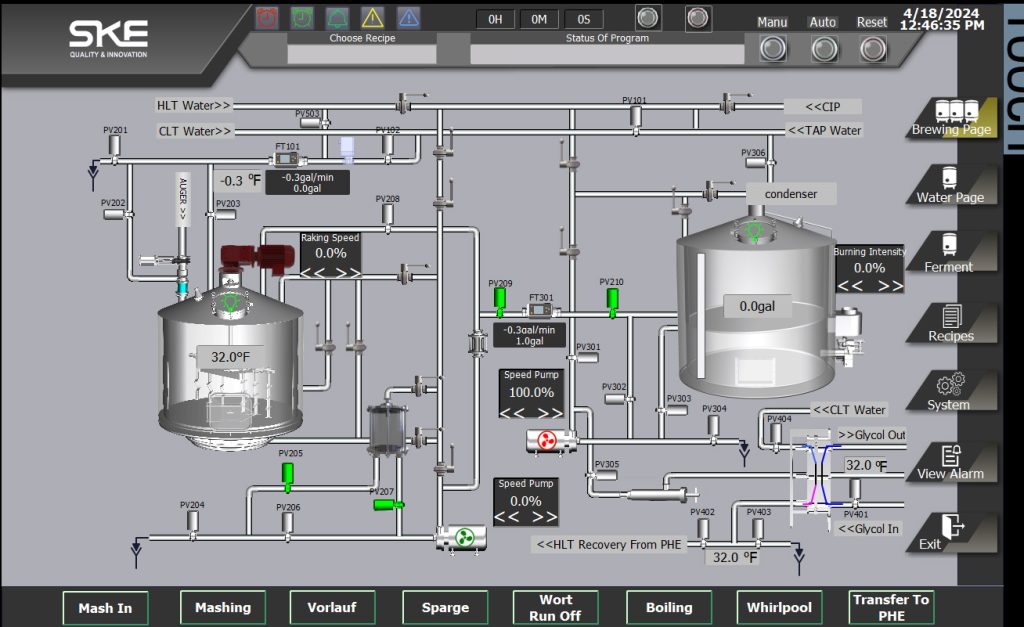

SKE Ketle&Whirlpool Tank (KWT)

SKE ketle&whirlpool tank (KWT) has large head space (≥70%), which greatly reduces the possibility of wort overflow during intense boiling and also provides space for customers to carry out wort dilution and outflow from the boiling tank.

The design of SKE’s boiling kettle and whirlpool tank not only fully considers the boiling area to ensure sufficient space for accommodating hot trub, but also takes into account the whirlpool sedimentation effect to facilitate solid-liquid separation.

The inner wall is processed to be smooth and clean, with flat edges and no sharp corners. It is polished to a precision of 0.2μm and undergoes acid pickling and passivation. This reduces the impact of tank wall friction on the whirlpool sedimentation effect and avoids causing local turbulence or eddy currents.

Considering of safety, All SKE kettle and whirlpool tank is equipped with an IFM sensor on tank top to avoid over-boiling and overflow during boiling.

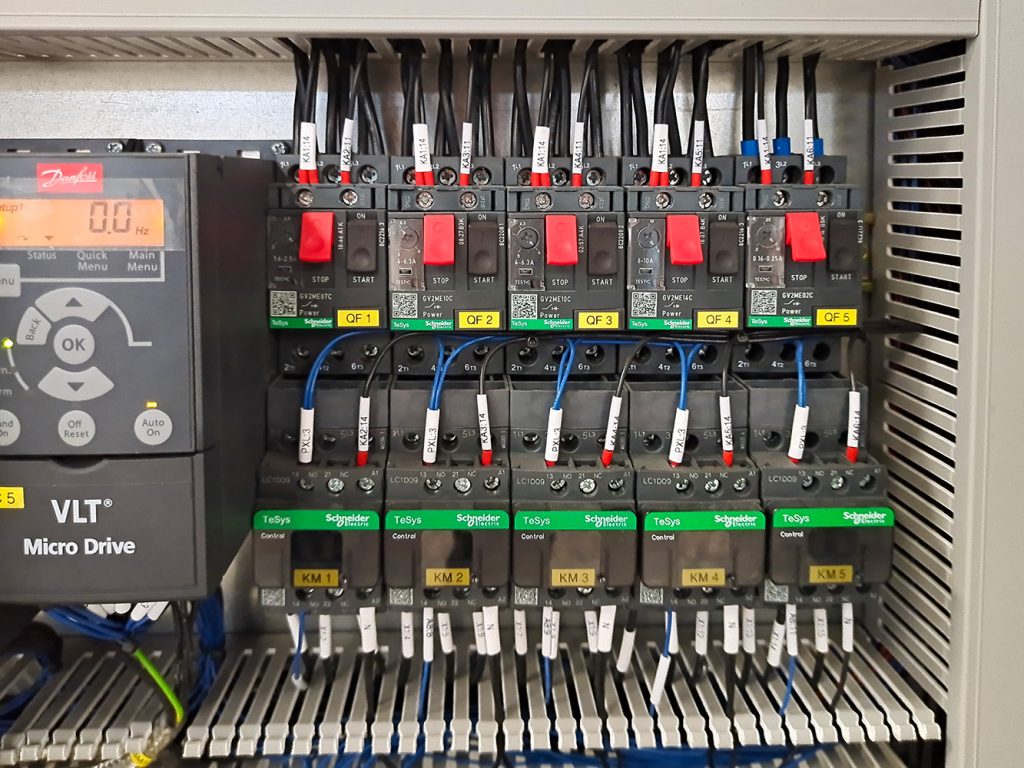

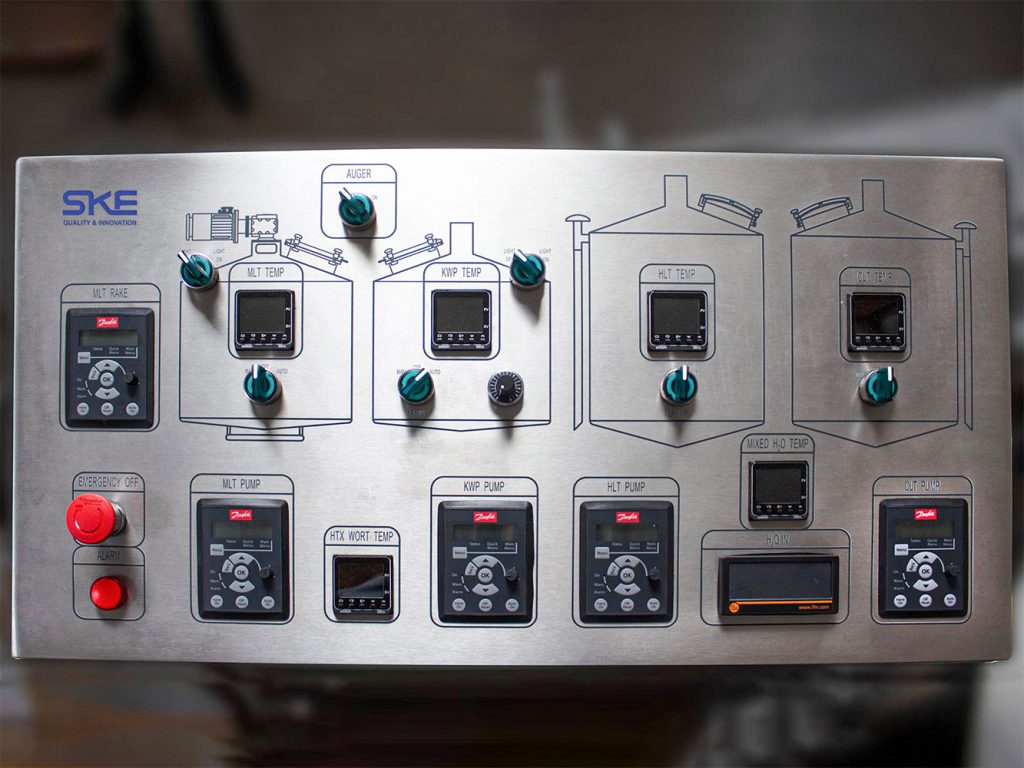

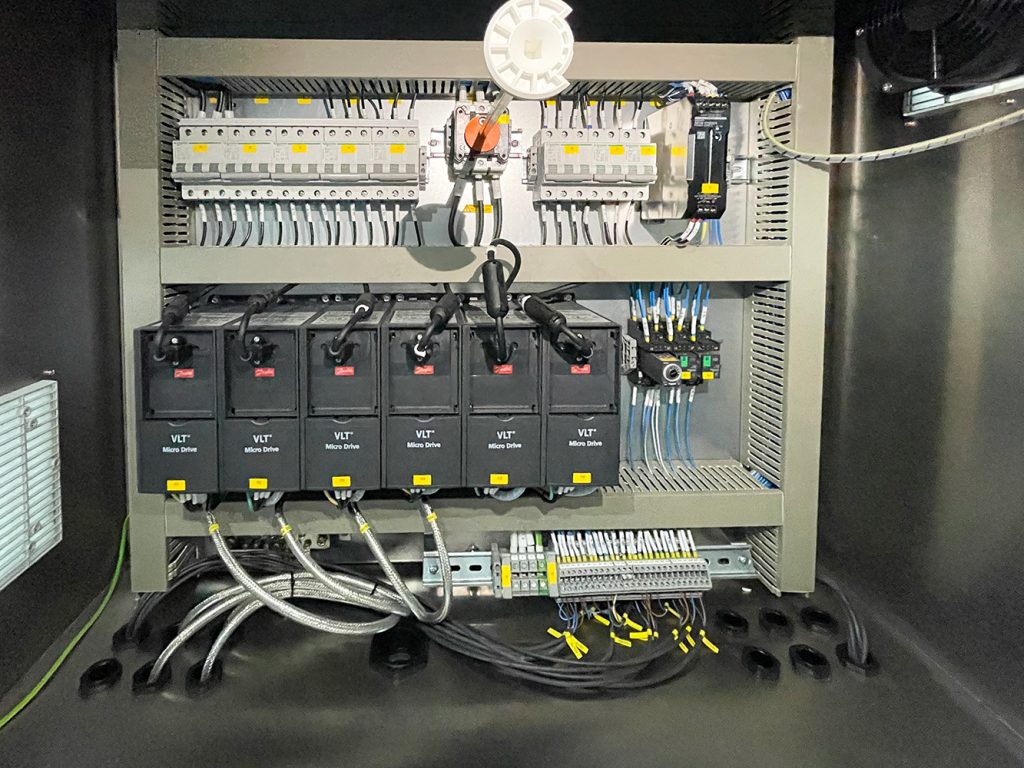

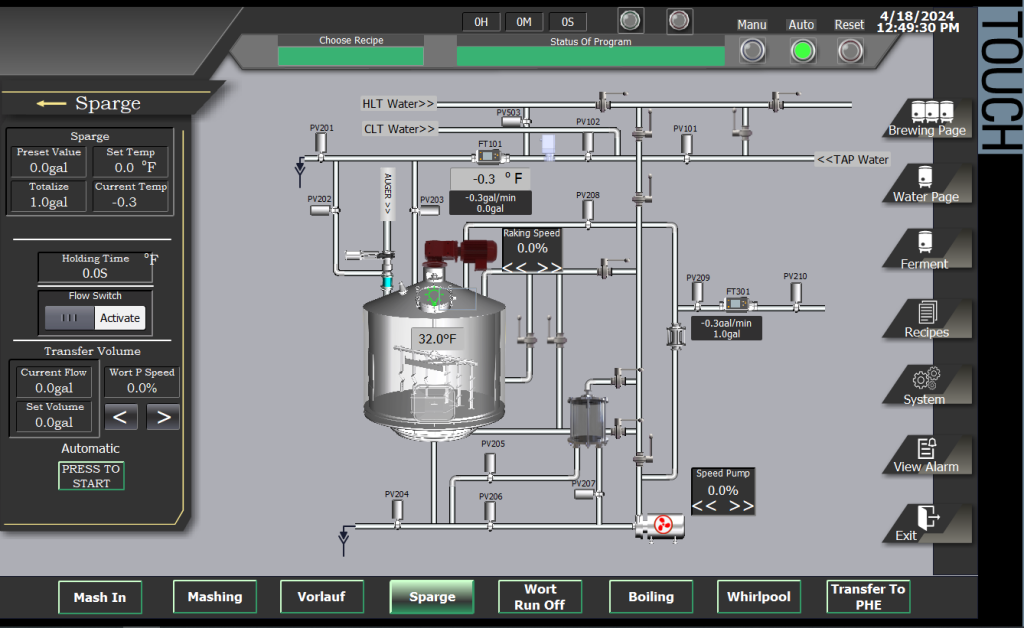

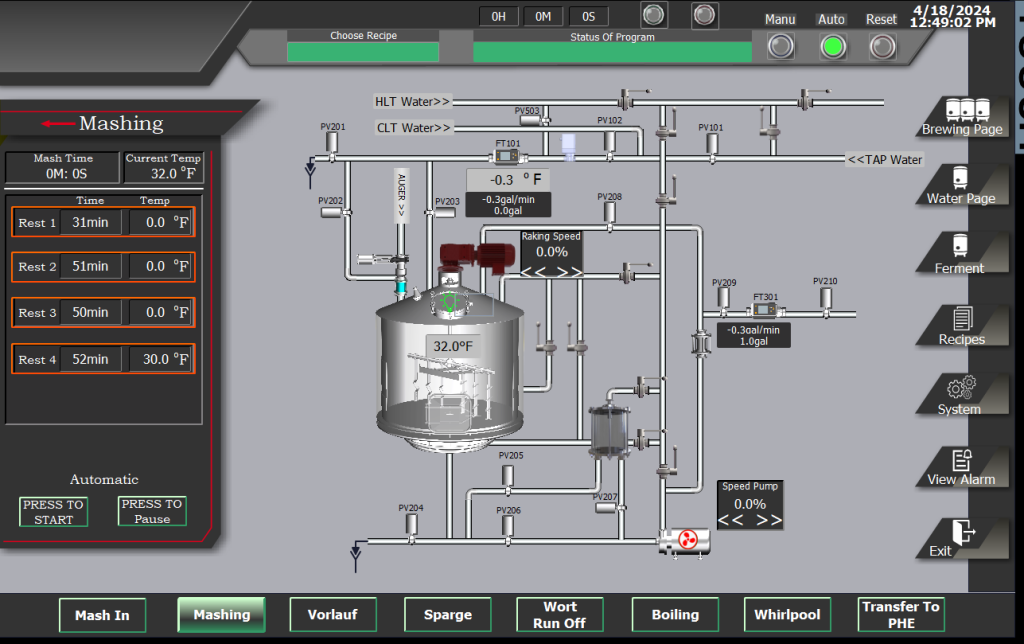

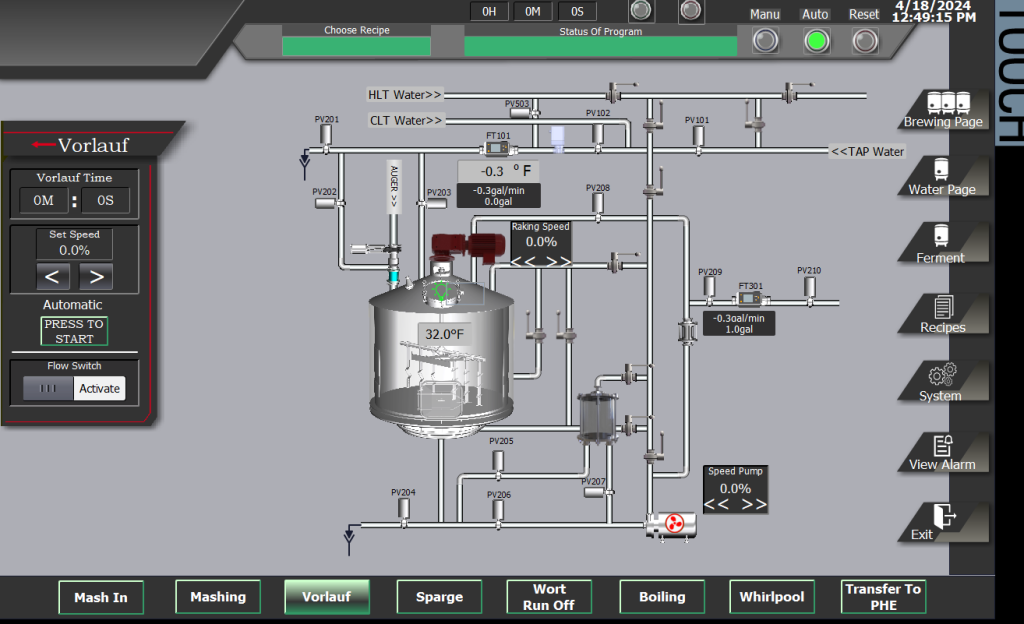

Control System

SKE control cabinet is semi-automatic which is specially designed for small size brewery. The cabinet is welded on brew deck and mounted all international famous brand of elements and instruments, including Omron temperature controllers, Danfoss VFDs, IFM flowmeters, temperature sensors, Schneder DC power, breaker, switches, relay, etc

Manual Control

SKE manual control system is specially designed for brewhouse pro.

The cabinet is welded on brew deck and mounted all international famous brand of elements and instruments, including Omron temperature controllers, Danfoss VFDs, IFM flowmeters, temperature sensors, Schneder DC power, breaker, switches, relay, etc .The brewhouse function including :

- Adjust speed of rake system, lauter pump and whirlpool pump

- Tank Light control on Panel

- Temperature of MLT displayed and Auto control

- Temperature of KWP displayed and Auto control

- Temperature of HLT displayed and Auto control

- Wort Temp <Post wort cooler> Display

- Temperature of mixing station display

- Brewing water and sparging water volume measure

- Kettle Tun Anti-Over boiling protection

- Two emergency stop buttons on brewhouse, one on brewhouse cabinet and another one nearby spent grain door

- Alarm Buzzer

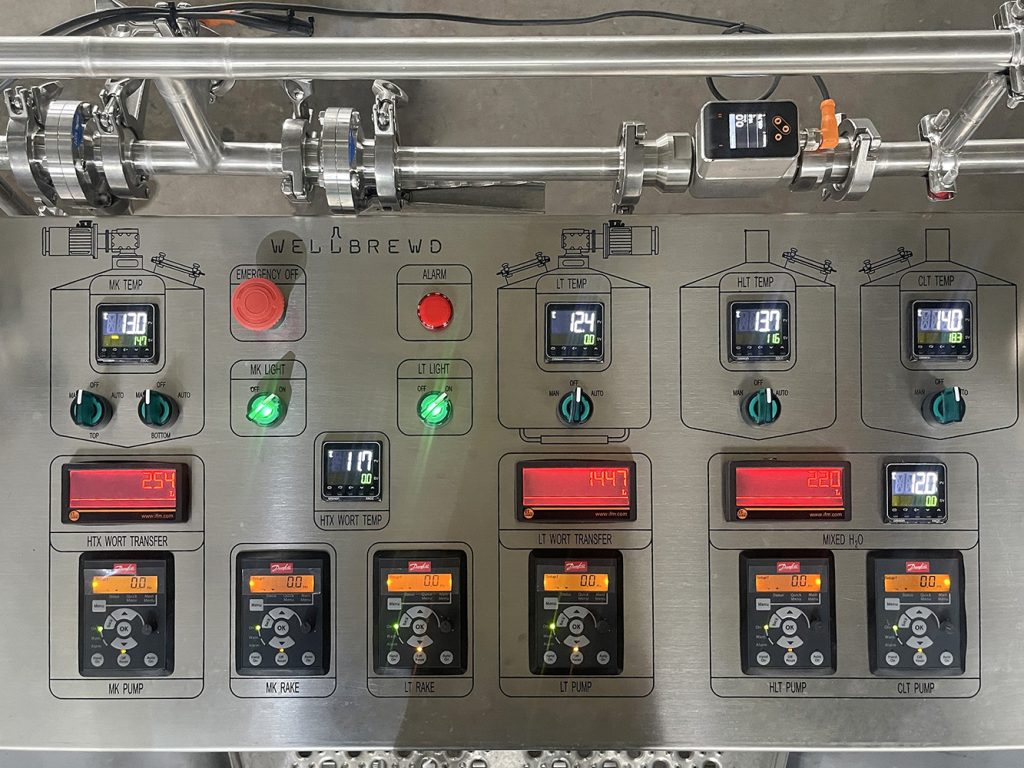

Semi-Auto Control

SKE’s semi-automatic electrical control system is suitable for BREWHOUSE PRO and BREWHOUSE SENIOR.

The semi-automatic design includes two operating modes: manual and automatic, allowing brewers to switch freely according to actual needs. This design not only simplifies the operation process but also provides possibilities for different customers to explore more automated processes.The brewhouse function including:

Material Auto Flow Control

- Mash Flow Auto Control

- Wort Flow Auto Control

- Water Flow Auto Control

- Draining Auto Control

Temperature Auto- Control & Display

- MLT,KWT HLT, CLT Temperature Auto Control

- Water Mixing Station Temperature Auto Control

Volume Recording And Auto Control

- Water Mixing Station with IFM Flow Meter for measuring/auto-control filling volume for MLT water filling & sparge water filling

- IFM flowmeter between MLT and KWT to measure and record wort flow between MLT and KWT during volarf and run-off.

Motor Speed Control

- Lauter pump speed (Lauter&Varlarting Speed) Auto Control

- All Pump On/Off and speed control with VFD by programming setting

- Mill& Chain Conveyor Motor On/Off Auto-Control and Speed Control by VFD by programming setting

- Raking Machine On/Off Auto-Control and Speed control by VFD during mashing/lautering by programming setting

Alarm& Lighting Control

- Emergency Stop on brewhouse cabin and MMT

- Tank lights ON/OFF

- Over-Boiling Protection on KT

- Compressor-Air for Brewhouse Low-Pressure Protection/Alarm

- Alarm buzzer function

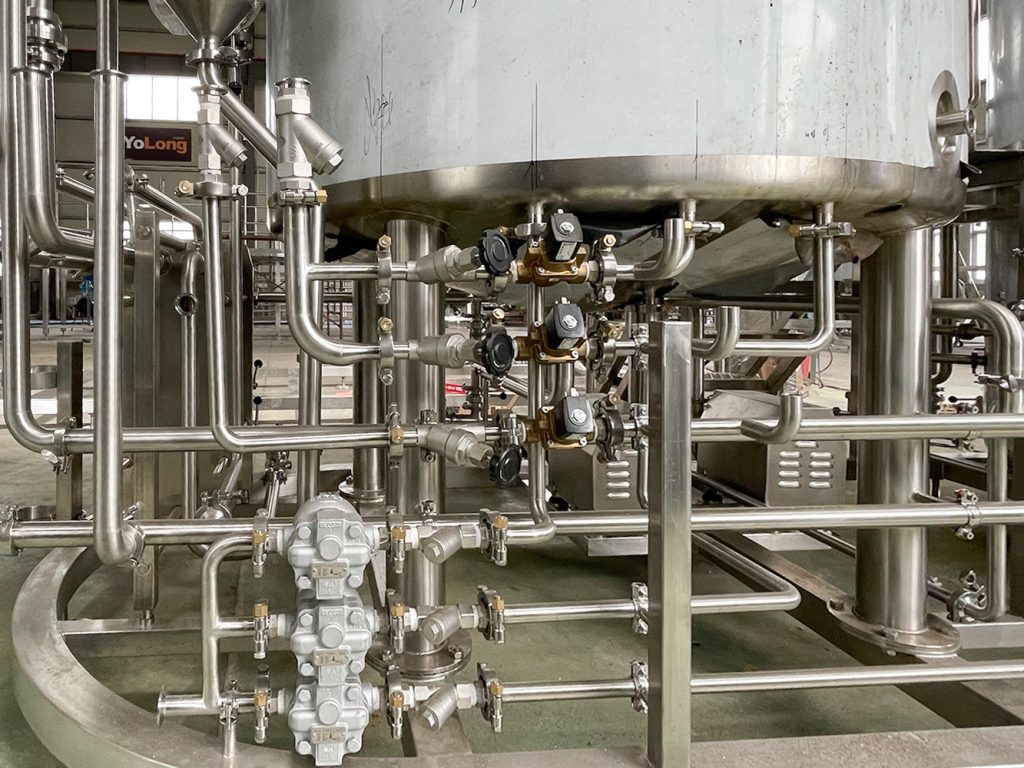

Brew Skid&Piping System

SKE brewing system adopts integrated skid-mounted design, integrating all components: brewing tanks, pipelines, pumps, plate heat exchangers, and various sensors onto a skid platform. This design significantly simplifies the on-site installation process for brewer while reducing the risk of equipment damage during transportation.

- Platform Design: Focus on Practicality and Safety. The platform uses non-slip materials and is pre-equipped with a drainage structure.The platform is made of high-quality SS304, ensuring strong structural stability.The angle of the supporting ladder is ergonomically optimized, making it easier and safer for operators to climb up and down the platform.

- Pipeline System: Highly Integrated Layout with Fluidity and Hygiene Standards.

- Pipe diameters are precisely calculated to ensure stable material transfer flow rates, eliminating hygiene dead spots at the source.The brewing water pipeline is fully matched to the flow demand and temperature control accuracy of brewing water. For wort pipelines, the transfer flow rate is strictly controlled — it prevents excessive flow from causing turbulence (which affects quality) and avoids slow flow from leading to material stagnation and deterioration. Especially for lautering and run-off pipelines, the design fully meets the differentiated flow rate requirements of filtration and transfer stages.

- Valve positions are set according to brewers’ daily operation and maintenance habits, within easy reach, greatly improving operational efficiency.

- In addition, the system achieves automatic cleaning function for the entire mashing process (SKE) by optimizing valve configuration. No manual disassembly is required, making cleaning operations simpler and faster while ensuring uniform and thorough cleaning results.

Advantages

- Skid Design With Plug and Play System.

- Reasonable Design with Higher Brewing Efficiency.

- No Dead Leg For Pipelines and Tank.

- Self-Cleaning Function Including Hot Water Rinse and Caustic/Sanitizer CIP.

- Cutting-edge International Brand Instruments for Higher Reliability and Spare Parts are Accessible Worldwide.

- High End Piping, Valves, Pumps,PHX etc for Long-Lasting Performance.

- High Safety Standard to Secure Safety of Brewer, Stability of Beer and Long Life of Equipment.