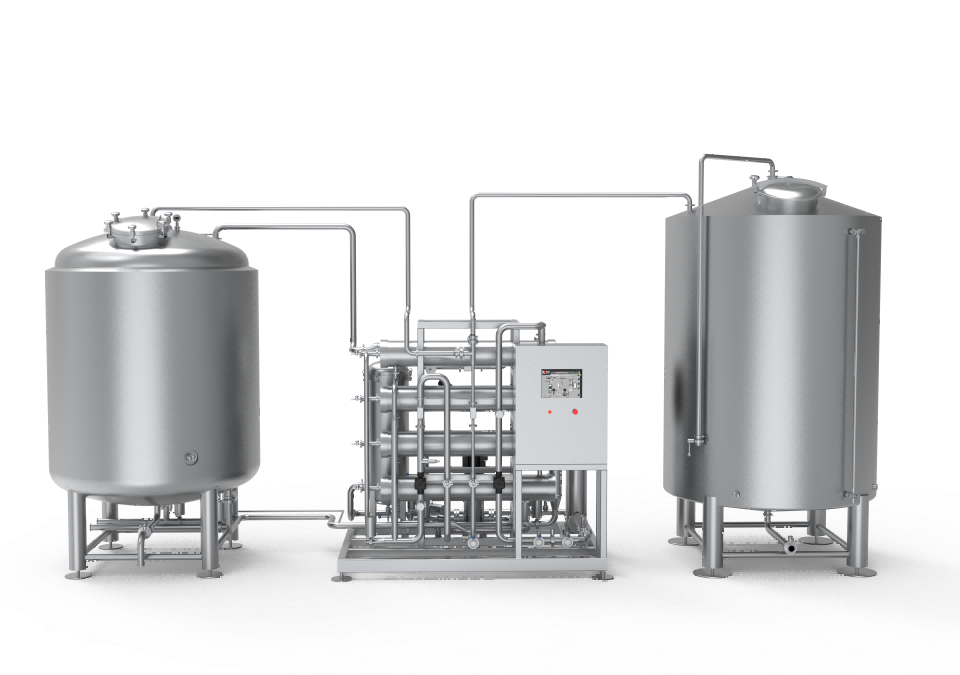

Dealcoholization Equipment Introduction

Dealcoholization equipment is essential for producing high-quality non-alcoholic beverages, from beers to wines. This equipment gently removes alcohol while preserving flavor, making it a cornerstone for health-conscious consumers and beverage brands. Whether you’re a home enthusiast or a commercial producer, understanding how dealcoholization works can help you create delicious alcohol-free drinks that meet growing market demand.

Types of Dealcoholization Equipment

Different methods require specialized tools. The most common types include:

Vacuum Distillation Units: Removes alcohol at lower temperatures to protect delicate flavors.

Reverse Osmosis Systems: Filters alcohol molecules through semi-permeable membranes.

Spinning Cone Columns: Uses vapor and condensation for precise alcohol separation.

Each type suits specific needs—vacuum systems excel in flavor retention, while reverse osmosis is ideal for large-scale production.

How Dealcoholization Works

The core principle relies on separating alcohol from the base liquid without compromising taste:

Heat Control: Lower boiling points under vacuum prevent flavor loss.

Selective Filtration: Membranes or cones target alcohol molecules.

Rebalancing: Reintroduces water or natural extracts to restore mouthfeel.

Understanding these steps ensures you choose equipment that aligns with your product goals.

Choosing the Right Dealcoholization Equipment

Consider these factors:

Scale: Home kits (1-5L) vs. industrial systems (100L+).

Budget: Entry-level models start at 500;commercialunitsexceed500;commercialunitsexceed10,000.

Beverage Type: Delicate wines need vacuum systems, while beers may use reverse osmosis.

At SKE, we offer FDA-certified systems for both small batches and factories, ensuring versatility and compliance.

Non-Alcoholic Beverage Production Equipment Safety & Quality Tips

Always use food-grade materials to avoid contamination.

Monitor temperature closely to prevent overheating.

Follow local regulations for non-alcoholic beverage labeling.

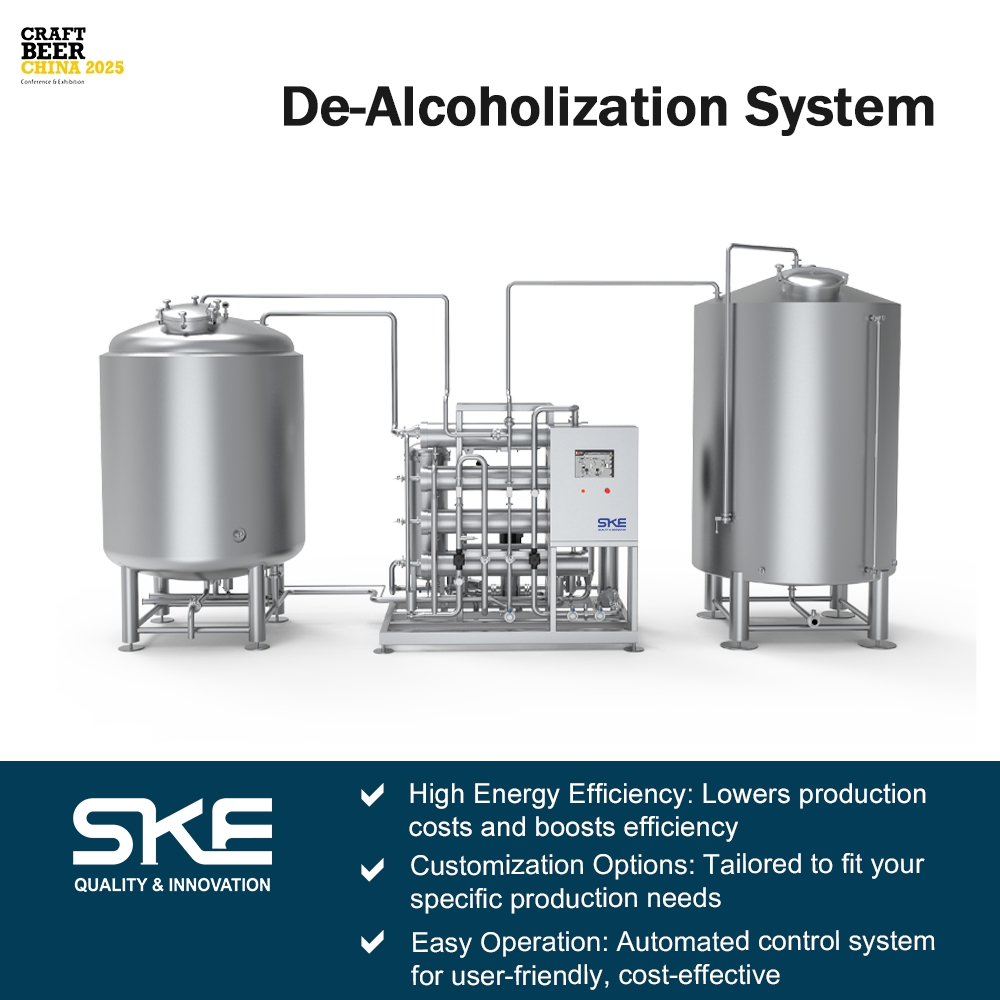

Why Choose SKE’s Dealcoholization Equipment?

SKE’s equipment combines cutting-edge technology with user-friendly design:

Flavor Preservation: Patented vacuum tech retains 95%+ original taste.

Energy Efficiency: 30% lower energy use than standard systems.

Explore our Dealcoholization Systems for tailored solutions.

FAQs

Q: What is dealcoholization equipment used for?

A: It removes alcohol from beverages like beer and wine, creating non-alcoholic versions without sacrificing flavor.

Q: Can I use homebrew equipment for dealcoholization?

A: Yes! SKE’s compact kits (e.g., HomeDealc Pro) are perfect for small batches.

Q: Is dealcoholized beer truly alcohol-free?

A: Most systems reduce alcohol to <0.5% ABV, meeting global “alcohol-free” standards.

Ready to Start? Contact SKE Today!

Email: info@skeequipment.com

Facebook: SKE Non-Alcoholic Solutions

Product Catalog: Download Here