”

What is a Beer Canning System?

A beer canning system is a specialized piece of equipment designed for filling, sealing, and packaging beer in aluminum cans. These systems play a crucial role in breweries of all sizes, providing efficient operations that adhere to industry standards. With the rise in popularity of canned craft beers, investing in a quality canning system is essential for breweries looking to maintain product freshness and shelf stability.

At SKE, we provide advanced beer canning systems that cater to various production scales, ensuring that every brewery can find a solution that aligns with its operational needs.

Benefits of Using a Beer Canning System

There are numerous advantages to utilizing beer canning systems. Firstly, cans are lighter and easier to transport compared to bottles, reducing shipping costs. Additionally, cans offer superior protection against light and oxygen, which can negatively affect the beer’s flavor. The ease of refrigeration and stacking makes cans an appealing choice for both retailers and consumers.

Moreover, breweries that opt for canning can tap into a broader market. With the convenience of cans, they can enhance their brand visibility and appeal to outdoor enthusiasts who prefer portable drink options.

Discover the innovative features of SKE’s beer canning systems that streamline the canning process while ensuring quality and safety.

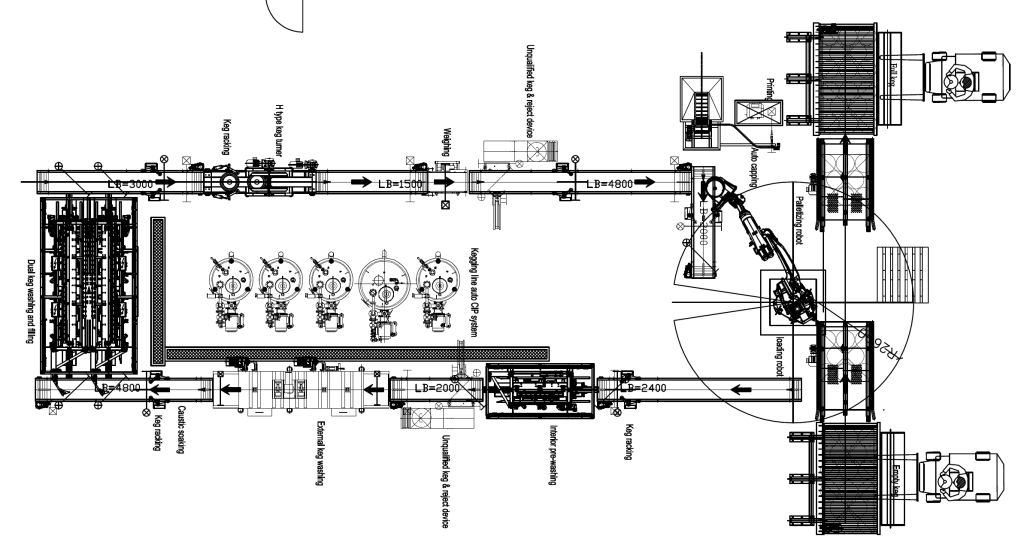

How a Beer Canning System Works

Beer canning systems operate through a series of steps, including cleaning, filling, sealing, and labeling. Initially, cans are washed and sanitized to remove any contaminants. Then, the system precisely fills each can with beer while maintaining the right level of carbonation.

Subsequently, the cans are sealed using lids, ensuring no air is trapped inside which could spoil the beer. Finally, the cans can be labeled and prepared for distribution. The efficiency of this process ensures that breweries can maximize their output while minimizing waste.

For more information on the technical principles behind efficient canning operations, take a look at our detailed article on canning process optimization.

Choosing the Right Beer Canning System

Selecting the best beer canning system involves considering various factors including production volume, budget, and automation levels. Smaller breweries may opt for manual or semi-automatic systems to stay within budget, while larger enterprises might need fully automated canning lines to meet higher demands.

Understanding your brewery’s needs is crucial. SKE offers a range of options tailored to meet diverse specifications, ensuring that breweries can operate efficiently and effectively.

Explore our range of products and see how each system can enhance your brewing operations. You’ll find essential details on our product page linked here.

Frequently Asked Questions

What is the average cost of a beer canning system?

The average cost varies depending on features and capacity, often ranging from several thousand to hundreds of thousands of dollars.

How do I maintain a beer canning system?

Regular cleaning, lubrication, and inspections are vital to maintaining canning equipment and ensuring it functions effectively.

Are automated systems better than manual ones?

Automated systems are generally more efficient and can handle larger volumes, but manual systems can provide cost-effective flexibility for smaller operations.

Contact Us

If you’re interested in learning more about our beer canning systems or need personalized assistance, we’re here to help! Reach out to us:

- Facebook: Visit our Facebook page

- Email: info@skeequipment.com

- Fill out our contact form below for more assistance!

“