Flash Pasteurizer innovations are changing how beverages and dairy maintain safety and flavor. Curious how a modern Flash Pasteurizer can pasteurize thousands of liters per hour while preserving taste? Read on — this guide explains what this unit does, how SKE builds next-gen systems, and what you’ll see at Drinktec 2025.

Table of Contents

What is the unit?

How the system works

Key components & SKE enhancements

Performance snapshot

Applications & Drinktec 2025 highlights

FAQs — what customers ask most

1. What is a Flash Pasteurizer?

A Flash Pasteurizer (also called HTST) heats liquid to a target temperature for a very short time to inactivate pathogens while keeping flavor and nutrients. Unlike batch pasteurizers, this continuous unit is ideal for high-throughput beverage and dairy lines and is commonly chosen when product quality and throughput must both be maximized.

2. How the system works

A modern HTST setup has three stages: regenerative pre-heating, precise holding, and rapid cooling. First, a regenerative heat exchanger pre-heats incoming product using the outgoing pasteurized stream. Then the product flows through a calibrated holding tube that maintains the exact time/temperature profile required for microbial inactivation. Finally, a cooling exchanger drops the product to refrigeration temperature quickly so volatile aroma compounds and nutrients remain intact.

3. Key Components

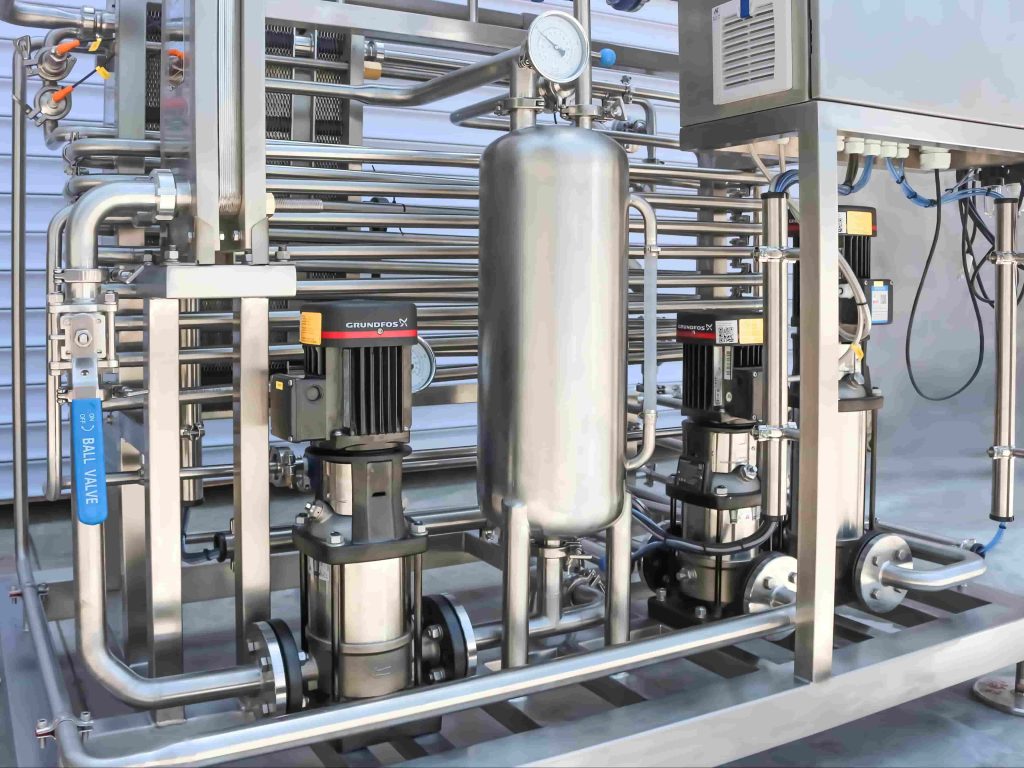

SKE designs Flash Pasteurizer skids with food-grade materials and industrial controls so OEM performance is matched with practical serviceability. Core components include regenerative exchangers, holding tubes, flow-diversion valves, CIP integration, and PLC/HMI recipe control.

| Component | Role | SKE Advantage |

|---|---|---|

| Regenerative Exchanger | Pre-heats incoming product using exit heat | Triple-plate design for improved thermal recovery |

| Holding Tube | Ensures required dwell time at target temp | Precision PID control |

| Flow Diversion Valve | Rejects under-processed product back to reheat | Automated zero-waste feedback loop |

| CIP Integration | Cleans the skid without disassembly | 30–45 minute validated clean cycles with low chemical use |

4. Applications & Drinktec 2025 Highlights

A Flash Pasteurizer suits milk, juices, RTD teas, plant-based milks and many clear beverages. At Drinktec 2025, SKE will demonstrate live processing, showing how the unit preserves volatile aromatics while delivering validated microbiological safety.Ask SKE engineers about retrofit options for legacy lines—seeing the technology on the show floor makes selection decisions far easier.

5. FAQs — what customers ask most

Q: What products are best for a Flash Pasteurizer?

A: Clear dairy, juices, teas, and RTD drinks benefit most because HTST balances safety with flavor preservation and throughput.

Q: How often should the pasteurizer be cleaned?

A: Daily CIP is recommended; SKE systems complete validated clean cycles in 30–45 minutes depending on loop size and soil load.

Q: What maintenance keeps the unit running optimally?

A: Quarterly plate inspections, monthly sensor calibration, and annual validation checks are typical. SKE offers service packages for ongoing calibration and spare parts to minimize unplanned downtime.

Ready to see a Flash Pasteurizer in action? The Flash Pasteurizer demos at SKE’s booth will show ROI and performance. Visit SKE at Drinktec 2025 to watch live demos and get a custom ROI estimate. Drop your product type or throughput in the comments and we’ll outline a SKE-based pasteurization plan tailored to your line.

Learn more about SKE’s Flash Pasteurizer skid design, capacity options, and service plans tailored to your production needs. Contact our engineers to schedule a demo or request performance data for your product.