Flash pasteurizer innovations are set to steal the show at Drinktec 2025 in Munich, and SKE’s booth will demonstrate why these systems are the gold standard for dairy, juice, and beverage producers. Picture raw milk entering a compact skid and emerging moments later as ultra-safe, nutrient-rich goodness—all without sacrificing flavor. Intrigued? Here’s your guide.

Table of Contents

1. What Is a Flash Pasteurizer?

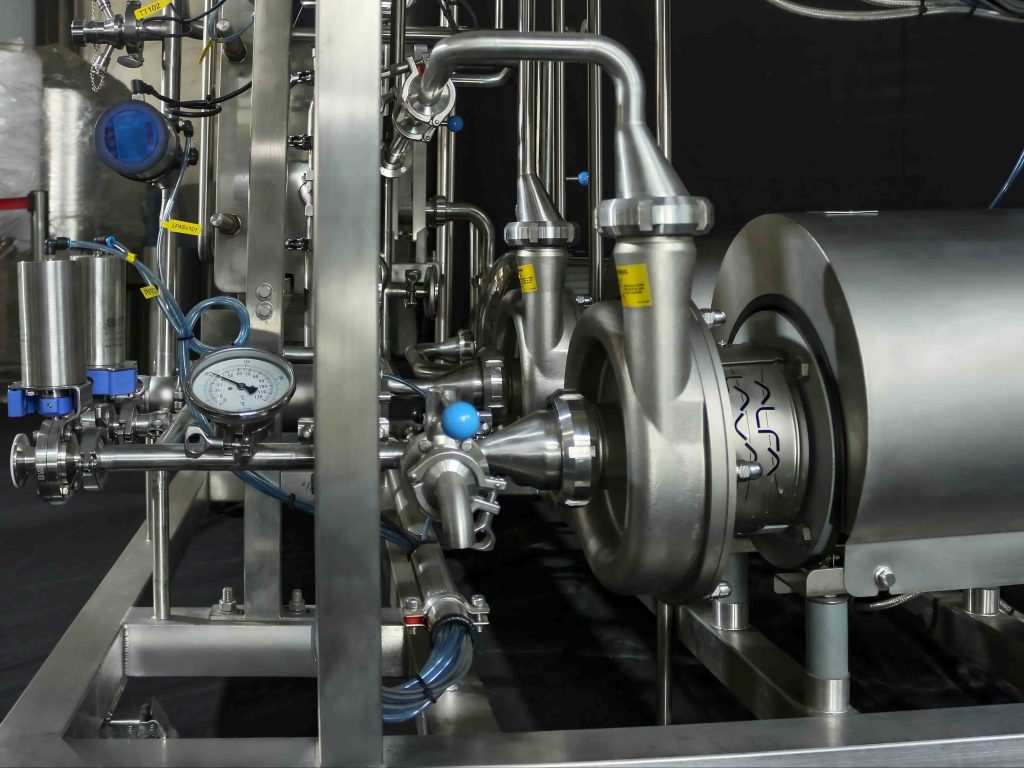

A flash pasteurizer is a continuous thermal treatment unit that heats liquid products—like milk or juice—to around 72 °C (161 °F) for just 15 seconds before rapid cooling. This process, often called HTST (High-Temperature Short-Time), inactivates harmful microbes while preserving taste and nutrients far better than traditional long-hold methods.

2. How a Flash Pasteurizer Works

The flash pasteurizer cycle follows three main steps:

Pre-heating: Incoming liquid is warmed by regenerative heat exchangers using outgoing pasteurized fluid.

Hold Section: Precise holding tube ensures the product remains at target temperature for the required 15 s.

Rapid Cooling: A second heat exchanger brings the product down to refrigeration temperature, locking in freshness.

SKE’s flash pasteurizer designs optimize flow rates and temperature control, guaranteeing every drop meets safety standards without cooked flavors.

3. Key Components & SKE’s Enhancements

| Component | Standard Role | SKE Innovation |

|---|---|---|

| Regenerative Exchanger | Pre-heats raw product with pasteurized exit | Triple-plate design for 18 % more energy recovery |

| Holding Tube | Provides 15 s residence at target temperature | Precision PID controls maintain ±0.1 °C accuracy |

| Cooling Exchanger | Rapidly cools to 4 °C | High-efficiency plates reduce footprint by 20 % |

| Flow Diversion Valve | Redirects under-temp product to reprocess | Automated feedback loop for zero-waste operation |

| Control Panel & Logger | Monitors and records cycle parameters | Cloud-connected HMI for remote monitoring and alerts |

By integrating these enhancements, SKE’s flash pasteurizer skid delivers up to 18 % lower utility costs and full GMP traceability.

4. Performance Comparison

| Metric | Conventional HTST | SKE Flash Pasteurizer |

|---|---|---|

| Energy Recovery | 60 % | 78 % |

| Footprint (m²) | 6.0 | 4.8 |

| Throughput (L/h) | 5,000 | 6,000 |

| CIP Cycle Time (min) | 60 | 45 |

| Nutrient Retention (Vitamins B & C) | 85 % | 93 % |

This table illustrates why SKE’s flash pasteurizer is ideal for producers seeking efficiency, quality, and space savings.

5. Applications & Drinktec 2025 Highlights

From dairy farms to cold-pressed juice lines, a flash pasteurizer ensures safety without compromise. At Drinktec 2025 in Munich, SKE will showcase live demos of its skid handling raw milk and almond milk, plus sessions on integrating automated CIP loops that cut cleaning time by 25 %. Don’t miss talks on nutrient-preserving heat exchange and real-time digital-twin simulations for process validation.

6. FAQs: Your Top Questions Answered

Q1. What products work best with a flash pasteurizer?

A1. Milk, fruit juices, teas, plant-based milks, and many other beverages benefit from the gentle, rapid HTST process.

Q2. How does a flash pasteurizer compare to UHT systems?

A2. UHT (Ultra-High Temperature) uses higher heat for shorter times, extending shelf life but altering taste. A flash pasteurizer balances taste preservation with moderate shelf extension.

Q3. What maintenance does a flash pasteurizer require?

A3. Regular CIP cycles, quarterly plate inspection, and annual sensor calibration keep performance optimal—SKE provides turnkey service plans for maximum uptime.

Ready to boost your product quality and operational efficiency with a top-tier flash pasteurizer? Share your toughest pasteurization challenges in the comments or visit SKE’s booth at Drinktec 2025 in Munich for an interactive demo. Let’s heat things up—together!