Imagine slashing contamination risks by 90% and cutting downtime in half—just by swapping out a single component. That’s the power of the right sanitary valve. In today’s ultra-competitive fermentation landscape, one tiny leak or hidden dead leg can spell disaster for your entire batch. But what if you could install 7 breakthrough SKE sanitary valve solutions that not only eliminate those hidden risks, but also turbocharge your yield and halve your cleaning time? Read on, because these game-changing secrets will transform your fermenters into productivity powerhouses—starting today

Why Piping and Valves Matter More Than You Think

Process Integrity: Even the smallest leak or backflow through an inferior valve can spoil thousands of liters of culture. A precision-engineered sanitary valve delivers bubble-tight sealing to eliminate contamination risks and protect your entire batch.

Operational Efficiency: Fast-acting sanitary valves streamline changeovers, deliver pinpoint flow control, and eradicate dead-leg areas—slashing downtime, speeding up CIP cycles, and boosting your overall yield.

Regulatory Compliance: Deploying sanitary valve designs that meet 3-A sanitary standards and use FDA-approved materials, along with fully traceable cleaning records, ensures you sail through audits and keep both regulators and customers satisfied.

Mapping Your Fermentation Piping Network

Industrial fermentation piping is typically organized into seven dedicated loops, each requiring precise valve choices—especially when you need a reliable sanitary valve solution to maintain sterility and streamline maintenance:

Sterilization & Cleaning (CIP/SIP)

Media: Steam, caustic, acid, sanitizers

Valves: Hard-sealed globe (stop) valves for steam service, paired with steam-rated diaphragm valves for Clean-in-Place to eliminate dead legs.Compressed Air & Aeration

Media: Filtered, sterile air; oxygen

Valves: Soft-seal stainless-steel globe valves for fine flow control, plus check valves to guard against backflow.Temperature Control

Media: Chilled glycol or water

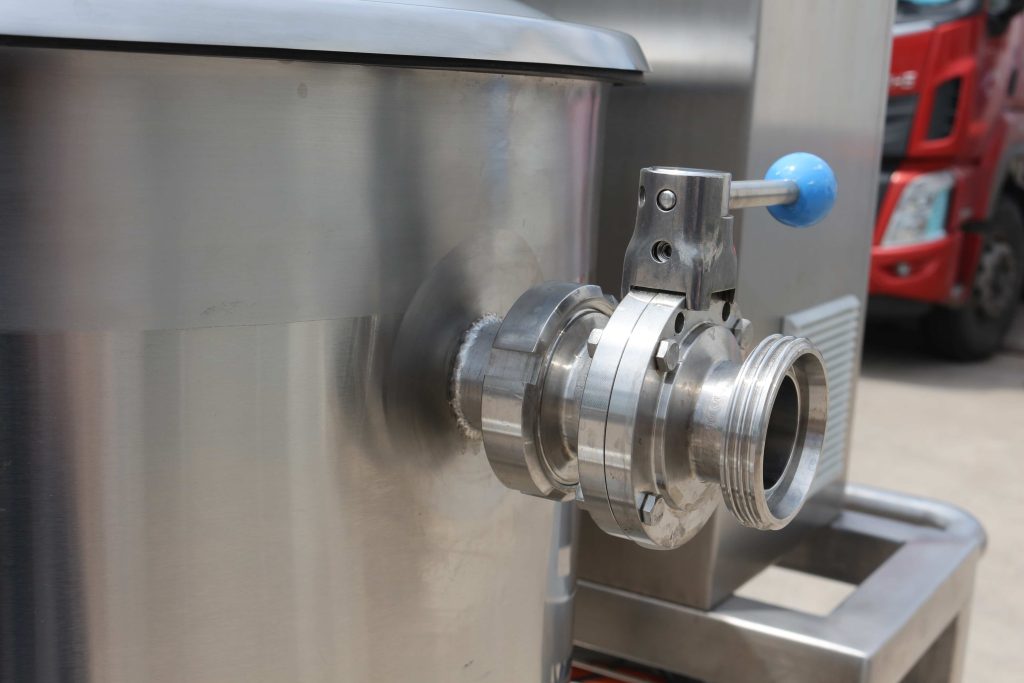

Valves: Durable ball valves for reliable on/off service and three-way diverting valves for precise hot/cold mixing loops.Feed & Harvest

Media: Culture broth, acids, bases, cleaning fluids

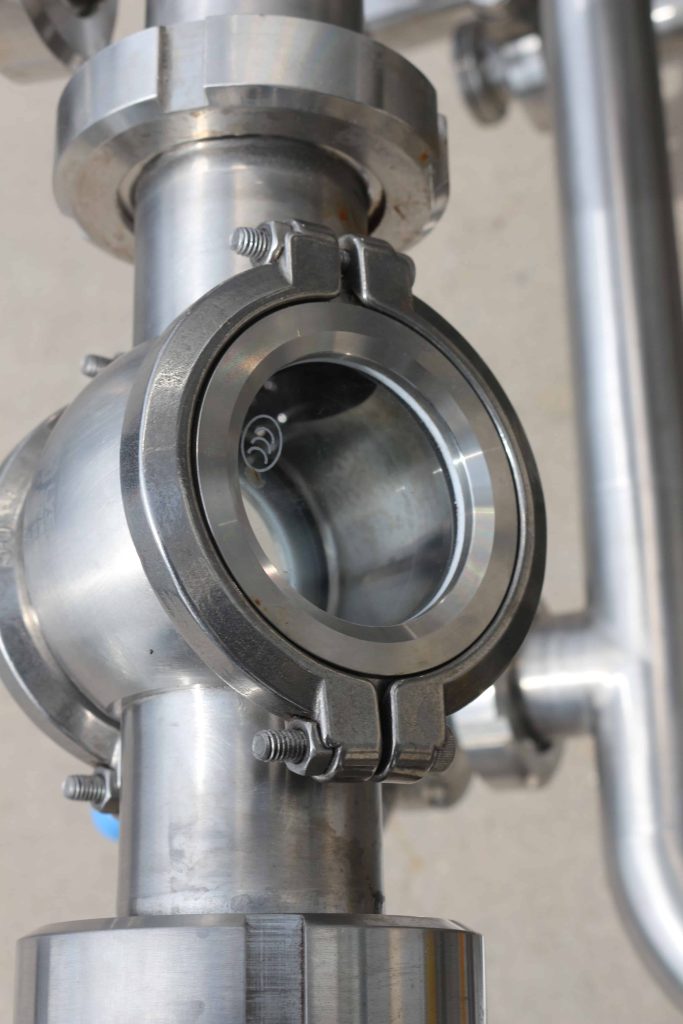

Valves: High-performance sanitary diaphragm valves—manual or pneumatic—to ensure full drainage and eliminate microbial harborage points.Inoculation (Seed Transfer)

Media: Sterile seed culture

Valves: Single- or double-membrane, high-purity diaphragm valves that uphold aseptic transfer protocols and minimize contamination risk.Exhaust & Venting

Media: CO₂, vapors

Valves: Pressure-relief valves and sterile vent filters mounted on isolated headers to prevent cross-contamination between tanks.Waste & Drain

Media: Spent broth, rinse water

Valves: Corrosion-resistant butterfly or large-bore ball valves designed for rapid evacuation of residues and easy cleaning.

By integrating the right sanitary valve in each loop—whether diaphragm, globe, or ball—you’ll boost system integrity, simplify CIP routines, and maximize your fermentation uptime.

Choosing the Right Valve: Beyond On/Off

| Sanitary Valve Type | Ideal Application | Key Benefits |

|---|---|---|

| Globe (Stop) Valve | Steam & compressed air throttling | Precise flow control; robust steam handling |

| Diaphragm Valve | Particulate-laden media, CIP/SIP | No dead legs; self-draining; minimal upkeep |

| Ball Valve | On/off service, aggressive media | Fast actuation; bubble-tight shut-off; low torque |

| Butterfly Valve | High-volume drain lines | Lightweight; cost-effective for large bore piping |

| Check (Non-Return) | Backflow prevention | Automatic operation; protects pumps & maintains sterility |

| Safety & Relief Valve | Overpressure protection | Critical safety function; required in steam loops |

Automation & Material Science: The Future Is Now

Smart Valves & Sensors: Upgrade to IO-Link or Ethernet/IP-enabled actuators—complete with integrated sanitary valve monitoring—to enable real-time data access, predictive maintenance alerts, and recipe-driven process control from anywhere.

Advanced Polymers & Coatings: Specify PTFE-lined or electropolished stainless-steel sanitary valves to minimize fouling, boost corrosion resistance, and dramatically extend service life under rigorous cleaning regimes.

Modular Skid Design: Choose pre-piped, skid-mounted manifolds outfitted with sanitary valves to slash on-site installation time, streamline factory acceptance testing, and simplify regulatory validation.

The Hidden Game-Changer: Configuration Strategy

Most engineers overlook the critical principle of piping independence, but it’s essential for contamination control:

Dedicated Vent & Drain Lines: Install individual headers for exhaust and waste—and equip each with a sanitary valve—so one tainted line can’t compromise multiple tanks.

Positive-Pressure Designs: Use strategically placed sanitary check valves to hold a slight positive pressure in your headers, effectively blocking ingress of airborne contaminants.

Oversized Headers: When sharing lines is unavoidable, increase header diameter by 25–50% and pair with high-performance sanitary valves to reduce pressure drops and guarantee full sterilization.

Ready for a Fermentation Revolution?

Picture this: a perfectly balanced, ultra-efficient fermentation tank suite where precision sanitary valves guarantee leak-proof sterility, and cutting-edge CIP equipment reduces cleaning cycles to minutes—not hours. Contamination becomes a distant memory, throughput skyrockets, and profit margins climb with every batch. That’s the impact of expertly engineered piping, top-quality sanitary valves, and state-of-the-art CIP equipment working in harmony.

👉 Surprise Offer: For the next 48 hours, I’m offering free 30-minute consultations to audit your fermentation tank system, recommend targeted sanitary valve upgrades and CIP equipment optimizations, and help you slash downtime by up to 20%. Spots are limited—reserve yours now and turn your process into a competitive edge!