With the final optimization of the mashing pipeline design completed, the 3D design of the four-vessel PILOT BREW, developed by SKE, has been officially finalized. This milestone achievement not only reaffirms SKE’s top-tier design capabilities in the beer brewing equipment sector but also vividly embodies its core business philosophy of “customer-first service” through overcoming challenges.

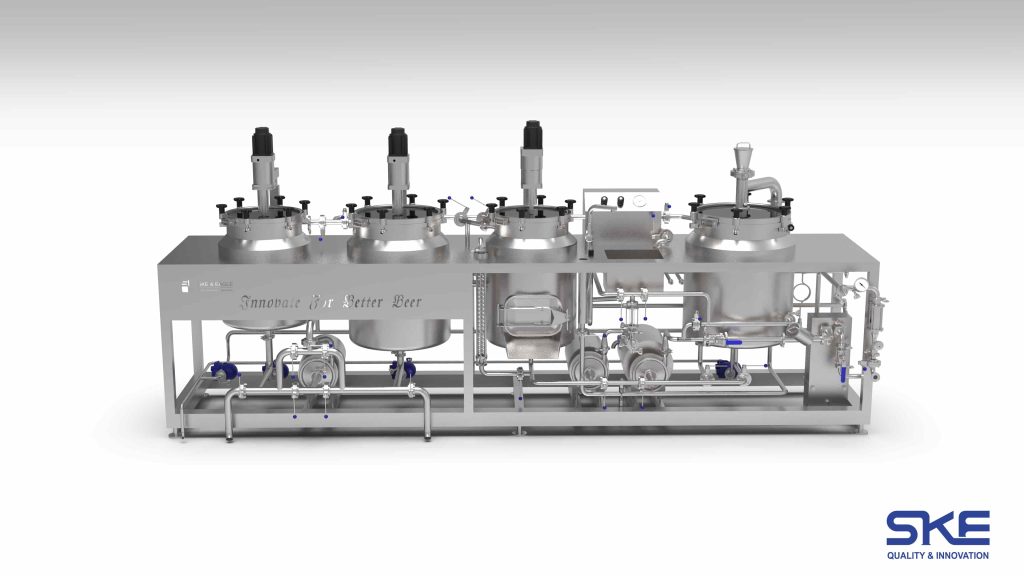

The 50L skid-mounted steam-heated four-vessel PILOT BREW equipment has set a national record as the smallest top-agitated mashing equipment. Featuring a highly integrated design, it cleverly incorporates four core units—25L mash cooker,50L mash tun, 50L lauter tun, 50L kettle& whirlpool tank—along with a sample spindle, plate heat exchanger, pumps, and a full set of pipeline systems onto a single skid. Its compact structure ensures operational convenience, achieves a perfect balance between aesthetics and practicality, and is equipped with advanced functions such as: decoction mashing, hot water rinse, and self-CIP to meet the diversified needs of customers.

This equipment is a custom-built laboratory-level solution by SKE for Jiangsu State Farms, a well-known malt producer in China, and will undertake three core missions:

- First, serving as a key experimental platform for special malt research and development.

- Second, providing pre-process verification for its upcoming 10-ton large-scale production line.

- Third, fulfilling the functions of teaching demonstrations and customer visit displays, acting as a visual window to showcase the enterprise’s technical strength.

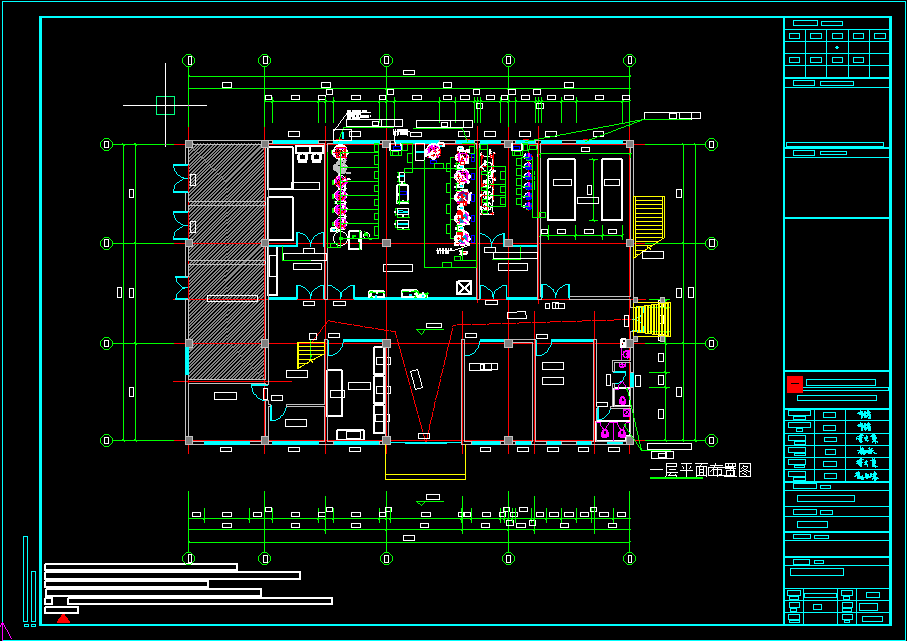

Looking back at the project process, its design difficulty can be described as an industry challenge. At the initial stage of project approval, Jiangsu State Farms faced difficulties due to conflicts between equipment size constraints and functional requirements, and began communication with SKE on a tentative basis. During the preliminary exchanges, SKE’s team, relying on its in-depth understanding of brewing processes and engineering innovation capabilities, resolutely took on this challenging project. Faced with tight deadlines and heavy tasks, SKE’s engineering team quickly conducted multiple rounds of in-depth communication with the customer, fully sorted out usage needs, design standards, and site constraints, and then launched intensive design work.

The customer’s core demands constituted the main difficulties in the design: within the limited space of a 50L tank with a diameter of only 40cm, it was necessary to integrate both the top-agitation function and reserve a glass manhole for easy observation. The combination of these two requirements imposed strict demands on equipment layout and component selection.

The first breakthrough was in solving the motor selection problem. Conventional three-phase asynchronous motors are too large; adopting a top-agitation design with such motors would severely damage the equipment’s aesthetics. After multiple rounds of plan demonstration, SKE innovatively selected servo motors. These motors not only offer high transmission accuracy but also perfectly fit into the compact space due to their small size, while significantly reducing subsequent maintenance difficulties, thus solving the dual demands of aesthetics and practicality in one go.

After confirming the motor selection, a new challenge emerged: how to design the motor installation structure to ensure the normal opening of the glass manhole? SKE’s design team developed an innovative movable motor device: the servo motor is mounted on a rocker support frame and connected to the agitation system through a coupling for flexible connection. During the feeding stage, the coupling only needs to be disconnected, and the motor can be moved to one side of the tank along with the rocker, allowing easy opening of the manhole. During the agitation operation, the rocker is reset and connected to the transmission system to resume operation. Meanwhile, to address potential vibrations during agitation, engineers specifically added a bottom support structure to the agitation system. Two support points hold the agitation shaft, enhancing structural stability, suppressing vibrations, reducing deformation, ensuring transmission accuracy, and guaranteeing smooth operation and service life.

When this innovative solution was submitted to Jiangsu State Farms, it received high recognition from the customer. The project leader shook hands with SKE’s chief engineer and praised: “Within such a short period, being able to come up with such a perfect solution that balances details and innovation, SKE’s professional strength is truly admirable!”

“Pursuing first-class design and adhering to high-quality service” is not just a slogan for SKE, but an operational principle integrated into every project. The successful conclusion of the 50L PILOT BREW design is another vivid practice of this concept. We look forward to this equipment playing its maximum value in Jiangsu State Farms’ laboratory, injecting strong impetus into the research and development of special malt, and helping the customer create considerable economic benefits. We also look forward to collaborating with more industry partners in the future to solve process challenges through innovative design and jointly elevate the brewing industry to new heights.