- How does SKE Rebirth a Used Brewing Equipment

Many people believe old equipment means outdated and inefficient, but in our view, used equipment carries history and stories and should be revitalized.

Recently, we undertook a refurbishment project for a copper-clad beer brewing equipment and let it continue to work well in new brewery.

Past Life

In 2019, SKE team had the great opportunity to manufacture brewing system for Mercedes Me in China.

That was a amazing and big challange to design, fabricate and install project to match luxuary feeling with Mercedes to customers. With much energy and work involved, our team partner with a famous brewing conculting company in Au and a well-known restaurant decorating company in Dubai delivered a well performed work together.

After years running, the customer closed the bar because of strategic adjustment and SKE purchased the equipment back.

New Life

In June 2025, a new customer in America found this equipment and decided to get it, so the new life of the used equipment start.

Let the used equipment work in another country is not a simple project, we will consider working condition, good looking and installation issues together.

This was a machine that had been in use for few years, with severe oxidation on the copper surface, obvious immersion marks inside the tank, corroded gaskets, reduced sensor accuracy, malfunctioning solenoid valves, and damaged components. The customer chose the old equipment due to budget constraints but still hoped it could maintain stable operation for the next few years.

When taking on this project, our approach was:

Even though the customer purchased used equipment, we treated it as a brand-new project. The refurbishment process is:

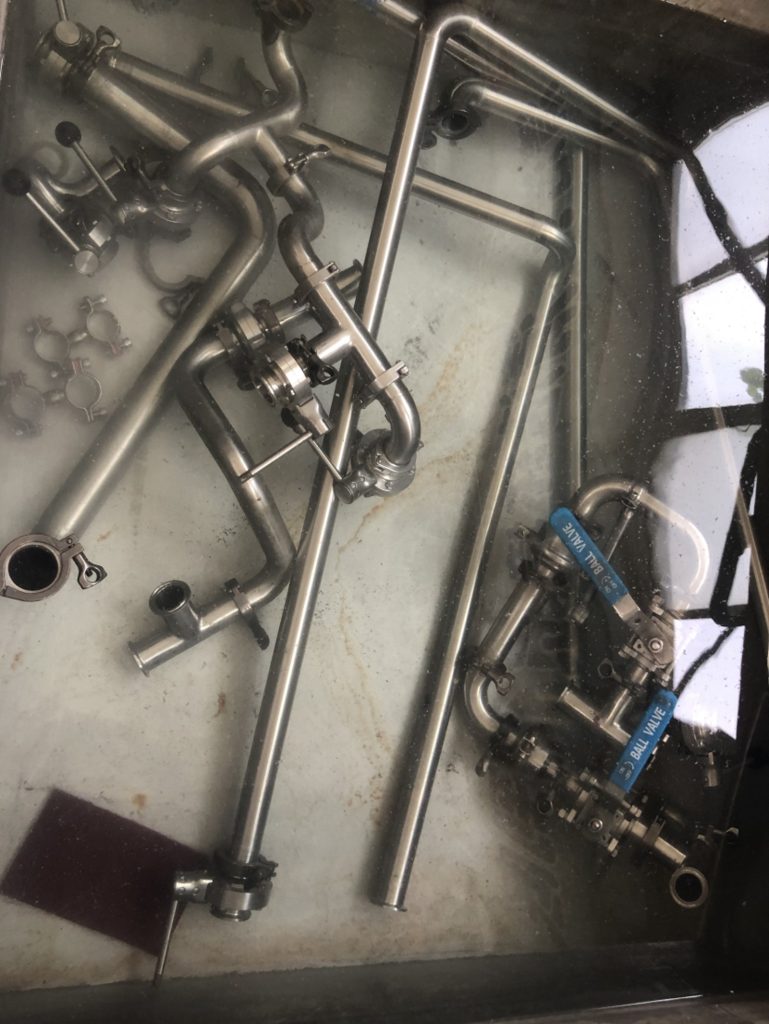

Step 1. Comprehensive inspection

Before disassembly, we conducted a comprehensive inspection of the overall condition of each piece of equipment in the mashing system, documented the findings, analyzed and discussed them, and determined the repair plan.

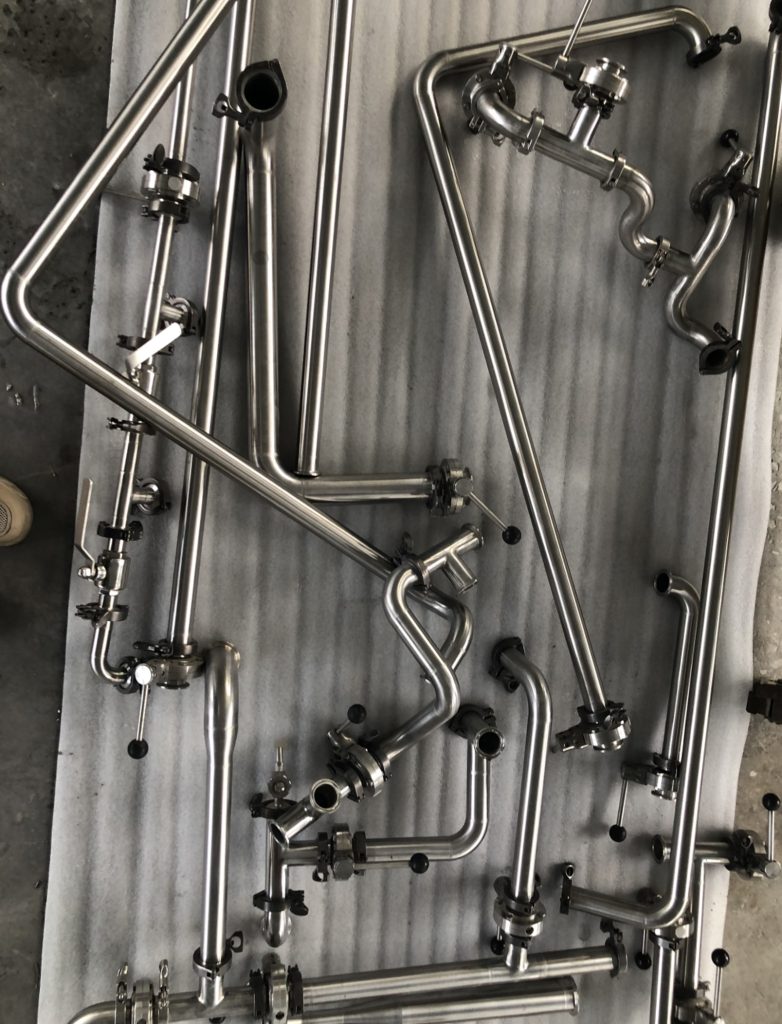

Step 2. Strict refurbishment

For issues such as oxidation on the outer surfaces, corrosion on the inner surfaces, and electrical equipment abnormalities, we employed methods such as polishing, acid washing and passivation, and replacement of critical components for refurbishment. Each step was strictly executed according to the manufacturing processes for new equipment.

Step 3. Performance Optimization

Refurbishment is not merely about restoring equipment to its original condition; it is also about enhancing its performance. Through re-calibration, we ensure that the equipment achieves stability, efficiency, and safety levels that are comparable to or even exceed its original state.

Step 4. Final Results

The refurbished copper-clad beer brewing equipment features a refreshed appearance and operates smoothly and reliably. Customers have reported significantly improved user experience, far exceeding their expectations for “used equipment.”

Step 5. Package & Delivery

Copper is sensitive for wet condition, the brewing equipment will be on the sea for one month, so we let all parties be fully dry and pack with cling film to insulate against the damp sea breeze to avoid rusting.

We believe that whether equipment can create value depends on our attitude toward the project. With dedication, even old equipment can be reborn.