”

Introduction to Beer Can Filling Machines

Beer can filling machines are vital for breweries looking to streamline their packaging process. These machines efficiently fill, seal, and sometimes label beer cans, ensuring product integrity and maximizing shelf life. A well-designed beer can filling machine will significantly reduce the risk of contamination and product spoilage. Learn more about how beer filling machines work at SKE.

How Beer Can Filling Machines Work

The operation of a beer can filling machine generally involves several steps: cleaning, filling, and sealing. Initially, cans are cleaned to remove dust and contaminants. Following this step, the machine fills the can with beer at precise volumes, ensuring minimal waste. Finally, the cans are sealed with lids to prevent oxygen from entering and affecting the beer’s quality. Understanding these processes is essential for breweries aiming to maintain product standards and operational efficiency.

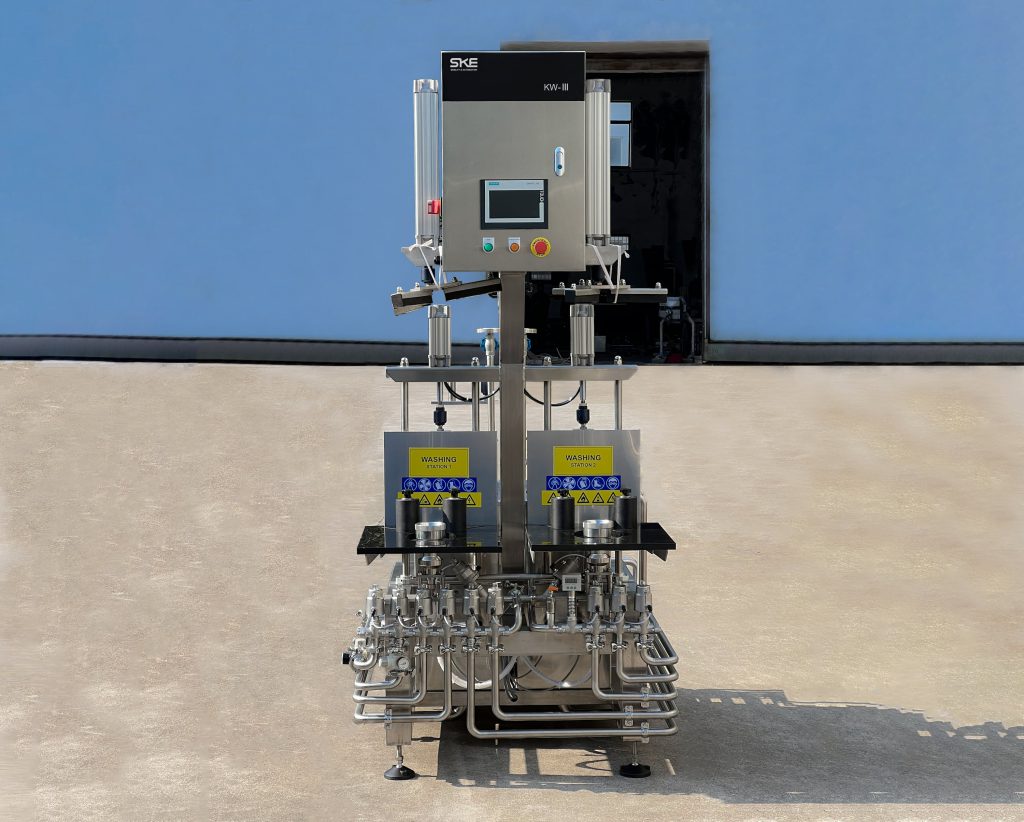

Key Features of SKE Beer Can Filling Machines

SKE offers top-of-the-line beer can filling machines that feature advanced technology, including automated filling systems, adjustable fill levels, and smart monitoring capabilities. Our machines are designed with user-friendly interfaces that facilitate setup and operation. Additionally, SKE’s filling machines are robustly built, ensuring longevity and reliability under various production conditions. Investing in SKE equipment not only enhances productivity but also elevates the quality of the final product.

Benefits of Using Beer Can Filling Machines

Utilizing a beer can filling machine brings numerous advantages. Firstly, these machines improve efficiency by reducing the time spent on the filling process. They also minimize human error and product wastage, subsequently lowering operational costs. Moreover, with features like precise volume control, they ensure consistency across batches of beer. For breweries focused on scaling their production, upgrading to a reliable beer can filling machine is a wise decision. For more tips on optimizing production, check out our article on optimizing brewery operations.

Applications in Modern Breweries

The applications of beer can filling machines in modern breweries extend beyond mere canning processes. They play a crucial role in craft breweries, large scale production facilities, and even microbreweries. A well-integrated filling machine from SKE enhances product throughput and quality while allowing breweries to experiment with can size and types, aligning with current market trends. Advanced methods, including vacuum sealing or nitrogen flushing, can also be employed to enhance freshness. Explore more about applicable technologies in the beverage industry in our latest insights on beverage industry technologies.

FAQs

What is the primary function of a beer can filling machine?

The primary function is to efficiently fill beer into cans, ensuring proper sealing and sanitation to maintain product quality.

How can I choose the right beer can filling machine for my brewery?

Choosing the right machine involves evaluating production capacity, fill precision, and additional features such as automation and ease of use. SKE provides expert consultation to find the ideal match.

Are SKE beer can filling machines suitable for craft breweries?

Yes, SKE beer can filling machines are designed to cater to breweries of all sizes, including craft breweries, providing flexibility and efficiency.

Get in Touch

Interested in enhancing your brewery’s production capabilities? Reach out to us to learn more about our beer can filling machines and other equipment. Connect with us on our social media, or contact us directly:

- Facebook: SKE Equipment

- Email: info@skeequipment.com

If you have any questions, feel free to fill out the contact form below, and our team will be happy to assist you.

“