”

Understanding Beer Tank Direct Systems for Modern Breweries

What is a Beer Tank Direct System?

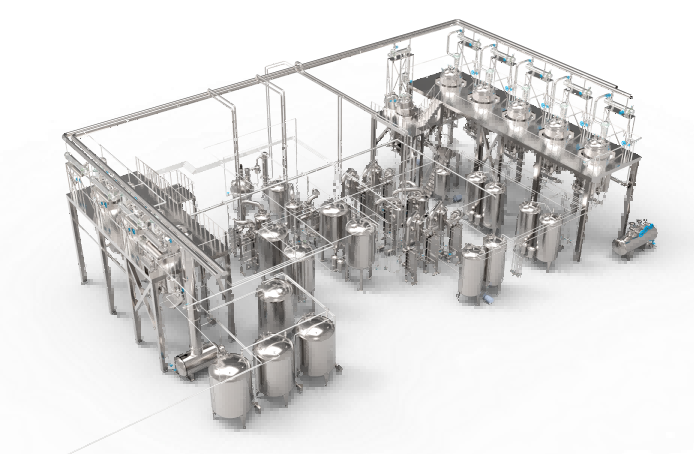

A beer tank direct system refers to a specialized brewing setup where beer is stored and served directly from the fermentation tank. This design optimizes workflow, reduces the need for additional transfer equipment, and minimizes oxidation, enhancing the overall quality of the beer.

At SKE Equipment, we specialize in high-quality brewery equipment, including efficient beer tank solutions designed to meet various production needs. Understanding the efficiency and utility of beer tank direct systems can enhance your brewing process significantly.

Benefits of Beer Tank Direct Systems

Beer tank direct systems offer numerous benefits to breweries looking to improve their production capabilities. Some of the primary advantages include:

- Reduced Oxidation: By minimizing the transfer process, the risk of oxidation is significantly lower, resulting in fresher flavors.

- Cost Efficiency: Fewer transfer pumps and hoses mean lower equipment costs and reduced maintenance expenses.

- Space Optimization: This system saves space within the brewery, allowing for more efficient use of valuable real estate.

For those considering optimizing their brewing operations, exploring the numerous advanced brewing techniques that incorporate direct systems could yield substantial advantages.

Key Features of Beer Tank Direct Systems

When evaluating different beer tank direct systems, it is important to consider the key features that contribute to efficient brewing:

- Temperature Control: Advanced systems include integrated heating and cooling capabilities to manage temperature during fermentation.

- Quality Materials: Stainless steel construction is common, offering durability and ease of sanitation.

- Automated Systems: Modern beer tanks often come equipped with automation controls for monitoring key brewing parameters.

Our beer tank systems incorporate these features to deliver maximum performance and reliability in your brewing operations.

Applications in Craft Brewing

The adoption of beer tank direct systems is becoming increasingly popular in craft breweries for several reasons:

First, the reduced complexity of brewing operations allows smaller breweries to compete with larger entities without compromising on quality. Secondly, these systems can be adapted for various batch sizes, making them versatile for different styles of beer.

For instance, SKE Equipment provides scalable solutions for craft brewing solutions that utilize efficient brewing methods to enhance production quality while providing flexibility for creative brewing practices.

Maintenance Tips for Beer Tanks

To ensure the longevity and performance of beer tank direct systems, regular maintenance is essential. Here are some key tips for maintaining your tanks:

- Routine Cleaning: Regularly clean and sanitize the tanks to prevent contamination.

- Inspection: Periodically inspect for leaks and other mechanical issues to address potential problems before they escalate.

- Calibration: Ensure that all automated processes are calibrated according to specifications to maintain efficiency.

For detailed information on proper tank maintenance, visit our article on tank maintenance.

Frequently Asked Questions about Beer Tank Direct Systems

What are the advantages of using a beer tank direct system?

Beer tank direct systems minimize oxidation, reduce costs, and optimize space, enhancing the overall brewing process.

How do I maintain a beer tank?

Routine cleaning, regular inspections, and calibration of system components are essential for maintaining optimal performance.

Can I use beer tank direct systems for different beer styles?

Yes, beer tank direct systems are versatile and can be adapted for various beer styles ranging from ales to lagers.

Contact Us

If you’re interested in learning more about our beer tank direct systems or have any questions, feel free to reach out:

- Facebook: SKE Equipment Facebook Page

- Email: info@skeequipment.com

We’d love to assist you further. Please fill out the contact form at the bottom of the page to get in touch with our team!

“