”

Introduction to Micro Brewery Pumps

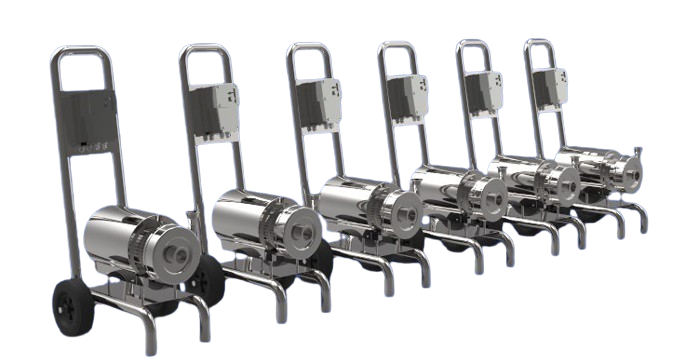

Micro brewery pumps are essential for the effective movement and transfer of various ingredients during the brewing process. These specialized pumps play a crucial role in ensuring that ingredients such as water, wort, and even carbon dioxide are efficiently circulated. At SKE, we understand the importance of having reliable equipment in your brewing process, which is why we supply high-quality micro brewery pumps tailored for the brewing industry.

Types of Micro Brewery Pumps

There are various types of micro brewery pumps on the market, each designed to serve different purposes. The most common types include centrifugal pumps, diaphragm pumps, and peristaltic pumps. Centrifugal pumps, for example, are favored for their efficiency in moving large volumes of liquid quickly.

At SKE, we offer a range of centrifugal pumps that ensure minimal shear on delicate ingredients. These high-performance pumps are ideal for preserving the integrity of your brew, making them a wise investment for any microbrewery.

If you’re interested in learning more about the types of pumps we offer, visit our product page.

Benefits of Using the Right Pump

If you select the right micro brewery pump for your brewing process, you’ll notice several key benefits. First, efficiency in brewing operations will increase as the pumping action enhances the mixing and circulation of ingredients. Second, the quality of the final product improves when ingredients are handled properly, which mitigates the risk of oxidation and other detrimental effects.

Moreover, investing in a quality pump reduces maintenance issues and downtime, allowing for a smoother brewing operation. Learn about our pumps that align with these benefits on the SKE equipment site.

How to Choose Your Micro Brewery Pump

Selecting the ideal micro brewery pump requires careful consideration of several factors, including flow rate, pressure, and the type of liquids being pumped. You’ll want to ensure that the pump you choose can handle the viscosity of your ingredients and the specific demands of your brewing equipment.

SKE’s knowledgeable staff can assist you in finding the right pump tailored for your brewery’s specific needs. Visit our contact page to get in touch with our experts today!

Maintaining Your Micro Brewery Pump

Once you’ve selected a micro brewery pump, it’s vital to maintain it properly to prolong its lifespan and maintain operational efficiency. Regular inspections and cleaning can go a long way. For example, consistent cleaning of the pump head and impeller will prevent clogs and ensure optimal functionality.

Additionally, consulting the manufacturer’s guidelines for maintenance will also be beneficial. Our SKE equipment offers manuals and support services to our customers, ensuring you have all the information needed for effective pump maintenance.

Frequently Asked Questions

What are the common types of micro brewery pumps?

The most common types include centrifugal pumps, diaphragm pumps, and peristaltic pumps, each suited for different purposes within the brewing process.

How does a micro brewery pump affect the brewing process?

A quality micro brewery pump enhances the efficiency of ingredient handling and ensures the quality of the final product.

How do I maintain my micro brewery pump?

Regular inspections, cleaning of components, and following manufacturer instructions for maintenance are essential for longevity and performance.

”