”

What is a Beer Unitank?

A beer unitank is a multifunctional vessel used in the brewing process to ferment and condition beer. Unlike traditional fermentation vessels that are separate from conditioning tanks, unitanks combine these two functions into one container. This makes them particularly efficient for breweries, especially those that produce a variety of beer styles.

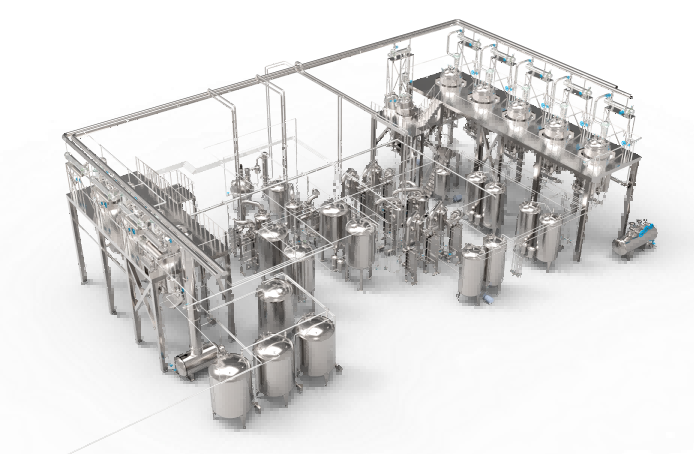

The design of the beer unitank streamlines workflow, reduces space requirements, and minimizes the risk of contamination, enhancing the overall brewing process. SKE provides state-of-the-art unitanks that incorporate robust materials and advanced technology to ensure optimal performance, tailoring solutions for breweries of all sizes.

By using a beer unitank, brewers can simplify their operations and improve their output consistency. This is crucial in meeting the growing demands of the craft beer market, where quality and efficiency are paramount.

Advantages of Using a Beer Unitank

The beer unitank presents several advantages that make it an invaluable asset for modern breweries. One primary advantage is the reduction of time and cost in the brewing process. Breweries can save on labor and resources by handling fermentation and conditioning in one unit, which is ideal for smaller operations with limited staff.

Additionally, using a unitank can increase the quality of beer produced. SKE’s unitanks are designed with temperature and pressure controls that allow for precise brewing conditions, leading to better flavor profiles and consistency across batches. Brewers can also experiment with different yeast strains and fermentation options without complicated setups.

Lastly, the compact nature of a unitank allows for more efficient use of space within the brewing facility. This is particularly beneficial for craft breweries that often operate in smaller premises. For those looking to enhance their brewing capabilities, our advanced brewing techniques can point you toward making the best choice with your setup.

How a Beer Unitank Works

Using a beer unitank begins with filling it with wort, which is the liquid extracted from the mashing process. The fermentation process then begins as yeast is added to the wort. The unique aspect of the beer unitank is that it allows for active fermentation to occur within the same vessel that conditioning takes place.

The tank is equipped with a variety of features such as pressure relief valves and temperature controls that ensure the fermentation environment remains ideal. As fermentation progresses, brewers can monitor key metrics, allowing for timely adjustments that can influence the final flavor and quality of the beer.

At SKE, our unitanks come with integrated monitoring systems that provide real-time data, empowering brewers to optimize their production. With these technologies, you’re ensured a more reliable and high-quality brewing process, crucial when aiming for perfection in every pint.

Best Practices for Using a Beer Unitank

To maximize the benefits of a beer unitank, several best practices should be observed. First, cleanliness is vital. Always ensure that the unitank is properly sanitized before use to avoid contamination, which can spoil an entire batch of beer.

Second, monitoring fermentation conditions such as temperature and pressure is essential. SKE unitanks are equipped with advanced control systems that allow brewers to maintain optimal conditions, but it’s important to remain vigilant. Thorough training on the equipment is recommended to avoid operational mistakes.

Lastly, understanding the yeast strain used is crucial for successful fermentation. Different yeast strains can lead to significantly different flavor profiles, so experimentation is encouraged as brewers refine their process. For more insights, consider visiting our fermentation science page for deeper information.

Frequently Asked Questions

What are the primary benefits of using a beer unitank?

The primary benefits include reduced brewing times and costs, improved beer quality, and more efficient use of space in the brewery.

Can I use a beer unitank for different types of beer?

Yes! A beer unitank is versatile and can be used for various beer styles by adjusting fermentation and conditioning settings.

How do I maintain a beer unitank?

Routine cleaning and sanitization are key. Regularly check for any signs of wear in pressure valves and temperature controls to ensure optimal functionality.

Contact Us

If you have any questions or need more information about our beer unitank solutions, don’t hesitate to reach out!

- Facebook: SKE Facebook Page

- Email: info@skeequipment.com

Additionally, please fill out the contact form at the bottom of the page for inquiries about our products and services.

“