Imagine stepping into your brewery at dawn, the aroma of toasted malt mingling with the promise of innovation as you stand before SKE’s state‑of‑the‑art beer making equipment. Whether you’re gearing up for a large‑volume industrial brew or experimenting with botanical spirits in your distillation pot, every component in your SKE lineup hums with potential—ready to help you craft liquid gold.

Precision Performance for Brewing Consistency

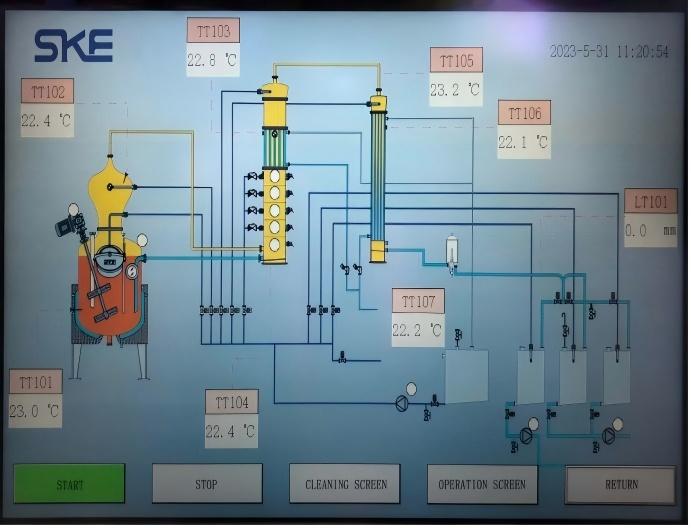

Nothing derails your day like an uneven mash. SKE’s beer making equipment features digitally controlled mash tuns that hold temperature within ±0.5 °C. That means whether you’re brewing 500 L or running pilot batches for an industrial brew, you’ll hit your gravity targets every time. No more guessing or extra cleaning cycles—just repeatable results.

Effortless Scale‑Up from Brewpub to Brewery

Transitioning from a 20 L system to an 1 000 L industrial brew line can feel daunting. SKE simplifies scaling: modular fermenters snap together, and the same beer making equipment interface you learned on small batches applies seamlessly to your distillation pot setup. This consistency shortens training time and keeps your creative momentum rolling.

Steam‑Jacketed Distillation Pot for Delicate Spirits

While many focus solely on beer, your brewery’s future might lie in spirits. An SKE distillation pot with a steam jacket gently extracts essential oils and flavors without scorching. Whether you’re crafting botanical gin or an artisanal single‑mash whiskey, steam distillation preserves nuance, turning leftover mash from your industrial brew into a profitable side venture.

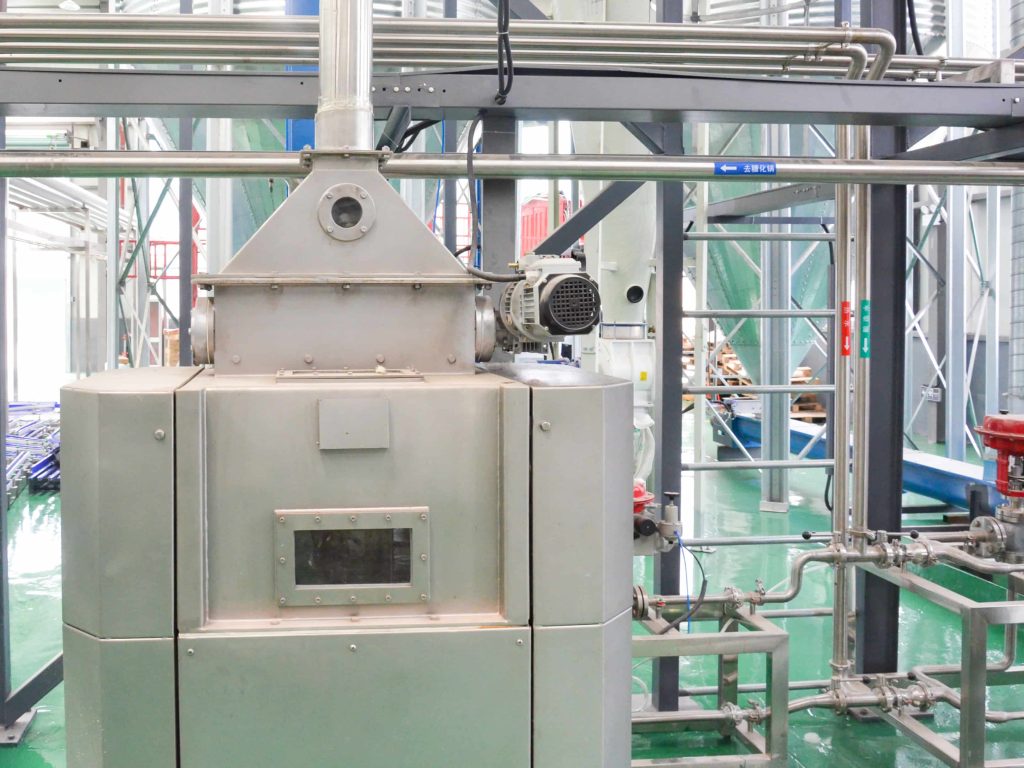

CIP Systems That Keep You Brewing

Sanitation is non‑negotiable. SKE’s integrated CIP (Clean‑In‑Place) for both beer making equipment and distillation pot components means no more disassembling tri‑clamps or wrestling hoses. Simply program your cycle, press start, and focus on recipe development instead of rinsing fittings for hours.

Emotional Highs: From Lab Coat to Beer Coat

Every brewer—from home hobbyists to corporate teams—knows the thrill of that first pour. With SKE’s precision beer making equipment, the emotional payoff intensifies:

Confidence knowing your mash profiles will match your tasting notes.

Pride when colleagues ask, “How did you dial in that perfect IPA bitterness?”

Connection as friends and customers line up for a taste of your industrial brew in the taproom.

These moments of joy—and the stories behind them—are why we keep brewing.

Sustainable Design Reduces Waste

Modern consumers demand eco‑responsibility. SKE’s beer making equipment reclaims heat from your distillation pot condensers and recycles rinse water in CIP loops. By lowering your energy footprint during each industrial brew, you not only save on utilities but also build a brand narrative around sustainability—a powerful marketing edge.

Five Pro Tips to Maximize Your System

Optimize Mash Thickness

Adjust water‑to‑grist ratios in your SKE mash tun for ideal enzyme activity.

Monitor Steam Flow

In your distillation pot, keep steam pressure steady to protect delicate botanicals.

Log Every Batch

Use SKE’s digital controllers to export CSV logs for gravity, temperature, and pH.

Rotate CIP Cycles

Run a high‑alkaline cycle weekly and an acid cycle monthly to keep all beer making equipment components pristine.

Host monthly workshops so every brewer can navigate SKE’s interface and troubleshoot minor issues.

These steps unlock the full potential of your SKE system, whether for industrial brew scale or distilling.

Real‑World Success Stories

Maria, head brewer at Coastal Craft Brewery: “After installing SKE beer making equipment, our production doubled without staff additions. Our new barrel‑aged stout sells out in days!”

Jin, founder of Urban Spirits Lab: “We repurposed surplus mash in our SKE distillation pot and launched a gin line. It’s now our fastest‑growing SKU.”

Their achievements show how the right gear empowers you to exceed goals and delight customers.

Bringing It All Together

From the steady warmth of the mash tun to the aromatic plume from your distillation pot, SKE’s beer making equipment and modular design redefine what’s possible in brewing and distilling. Whether you’re perfecting the next hop bomb or crafting a whiskey distilled from spent grains, SKE provides the precision, reliability, and human‑centered support your creative journey deserves.