Introduction

In the dynamic and competitive world of craft beer production, the role of brewery keg washers is pivotal. These specialized machines not only streamline the cleaning and sanitization process of kegs but also significantly impact operational efficiency and beer quality. This article delves deep into the intricate workings of brewery keg washers, their technological advancements, operational benefits, and their critical role in maintaining hygiene standards.

Understanding Brewery Keg Washers

What is a Brewery Keg Washer?

A brewery keg washer is a sophisticated piece of equipment designed specifically to automate the cleaning and sanitization of kegs used for storing and dispensing beer. By eliminating manual cleaning processes, keg washers ensure consistent cleanliness and hygiene, thereby safeguarding the integrity of the beer.

Components and Working Mechanism

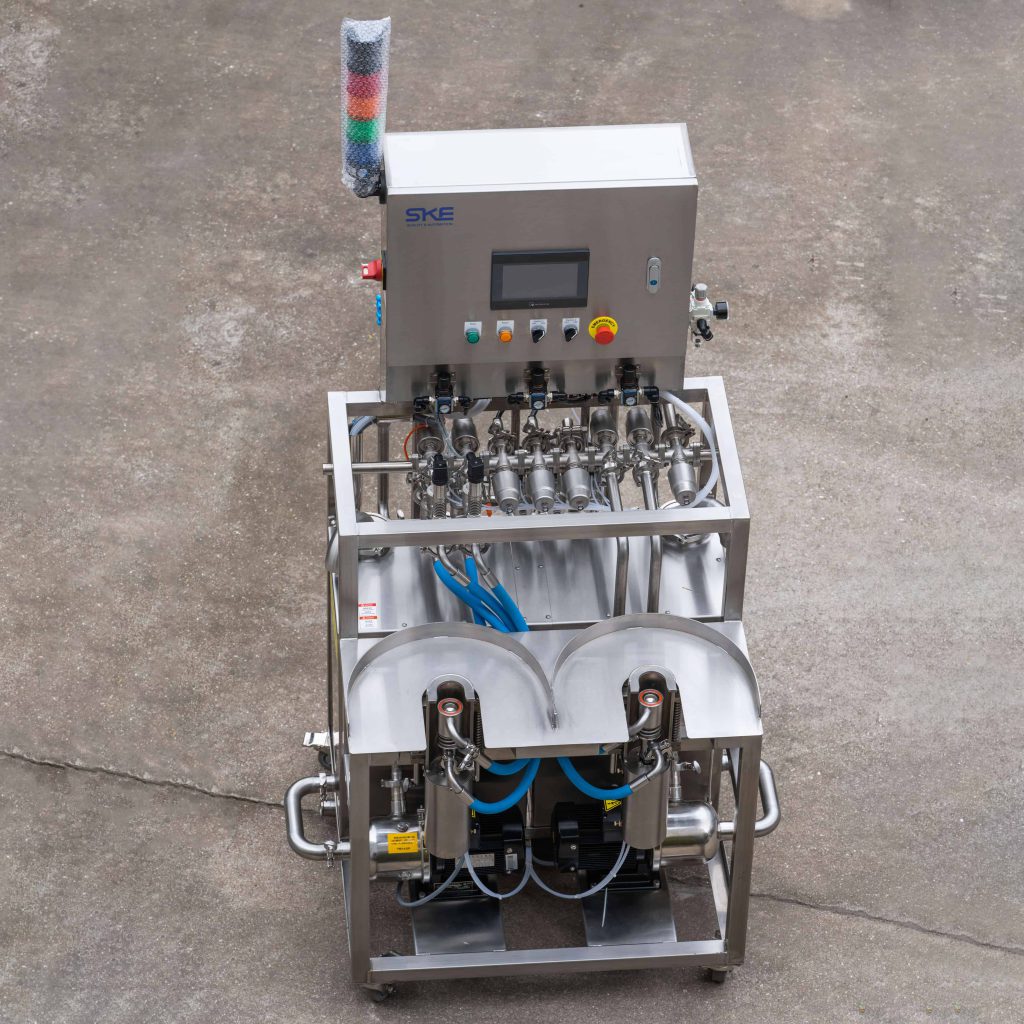

A typical beer barrel cleaning machine comprises several essential components:

- Cleaning Chamber: Where the kegs are loaded and secured for cleaning.

- Spray Nozzles: Distribute cleaning solution and water under pressure to effectively remove residues.

- Sanitizing Station: Ensures thorough disinfection of kegs post-cleaning.

- Control Panel: Allows operators to set and monitor cleaning cycles, ensuring optimal performance and efficiency.

Technological Advancements in Brewery Keg Washers

Automation and Efficiency

Modern beer barrel cleaning machines are equipped with advanced automation features that minimize human intervention and maximize operational efficiency. Automated loading and unloading mechanisms, coupled with programmable cleaning cycles, reduce turnaround times and enhance overall productivity.

Integration with Industry 4.0

Some beer barrel cleaning machines are now compatible with Industry 4.0 principles, incorporating IoT (Internet of Things) capabilities for remote monitoring and data analytics. This integration allows breweries to track cleaning metrics, optimize resource usage, and predict maintenance needs, thereby improving operational planning and cost-efficiency.

The Impact of Brewery Keg Washers on Production Efficiency

Streamlining Operations

By automating the cleaning process, beer barrel cleaning machines streamline operations and reduce labor-intensive tasks associated with manual cleaning. This efficiency improvement translates into faster keg turnaround times, enabling breweries to meet production demands without compromising on quality.

Ensuring Consistent Hygiene Standards

Consistency in cleaning and sanitization is critical in the brewing industry to prevent contamination and maintain beer quality. Brewery keg washers deliver uniform cleaning results, ensuring that each keg meets stringent hygiene standards before being refilled with beer.

Comparison of Cleaning Methods

| Aspect | Manual Cleaning | Automated Cleaning |

|---|---|---|

| Cleaning Time | Variable, longer | Consistent, shorter |

| Labor Cost | Higher | Lower |

| Cleaning Consistency | Dependent on operator skill | High |

| Resource Efficiency | Higher water and chemical use | Controlled usage |

Environmental Impact of Brewery Keg Washers

In addition to improving operational efficiency and maintaining high hygiene standards, brewery keg washers also contribute to sustainability efforts within the craft beer industry. These machines are designed to optimize resource usage, including water and cleaning chemicals, thereby reducing environmental impact compared to traditional manual cleaning methods. By minimizing water wastage and ensuring controlled chemical usage, beer barrel cleaning machines align with breweries’ sustainability goals, promoting responsible production practices without compromising on quality or efficiency.

Conclusion

In conclusion, brewery keg washers represent a cornerstone of modern craft beer production, embodying technological innovation and operational efficiency. By automating and standardizing the cleaning process, these machines enable breweries to uphold stringent hygiene standards while optimizing production workflows. As breweries continue to innovate and expand, the role of beer barrel cleaning machines will remain indispensable in ensuring the consistent delivery of high-quality beer to consumers worldwide.

FAQ

Q: How often should brewery keg washers undergo maintenance?

A: It is recommended that brewery keg washers undergo routine maintenance every 3 to 6 months, depending on usage and manufacturer guidelines, to ensure optimal performance and longevity.

Q: Can brewery keg washers handle different keg sizes and types?

A: Yes, modern brewery keg washers are designed to accommodate various keg sizes and types commonly used in the industry, offering flexibility and adaptability to brewery operations.