Home brewing equipment is the backbone of every great home brewery—and picking the right tools can turn your passion project into truly exceptional beer. By combining SKE Equipment’s precision engineering with BCB London–inspired best practices, you’ll unlock consistency, flavor clarity, and peace of mind. In this guide, we’ll tap into the excitement of that very first perfect pint, walk you through seven essential pieces of home brewing equipment, and answer the questions every brewer wonders. Let’s fire up the burners!

Why Home Brewing Equipment Matters

Home brewing isn’t just a weekend hobby—it’s a creative journey. The right home brewing equipment empowers you to:

Capture Nuance: Consistent heat and precise controls bring out deeper malt and hop character.

Save Time: Automated features free you to focus on recipe tweaks instead of constant monitoring.

Brew Safely: Built-in sanitation loops help prevent infections before they start.

Imagine taking that first sip, knowing your gear (from SKE Equipment, validated by BCB London processes) did the heavy lifting. That’s the pride you earn when you invest in top-tier home brewing equipment.

1. Digital Mash Tun with PID Control

Precision is everything in mashing. A digital mash tun with PID control holds your target temperature within ±0.5°F, ensuring enzymes work at peak efficiency.

| Feature | Basic Mash Tun | PID-Controlled Mash Tun |

|---|---|---|

| Temp Accuracy | ±3°F | ±0.5°F |

| Manual Adjustments | Yes | No (automated) |

| Mash Profile Capability | Single infusion | Step-mash programs |

| Emotional Benefit | “Did I hit 152°F?” | “My mash is on point!” |

Emotional pull: Remember your first stuck mash? A PID controller turns that anxiety into confidence.

2. Stainless-Steel Lauter Tun with False Bottom

Efficient lautering is key to avoiding grain bed compaction and maintaining runoff speed. A quality false-bottom design helps you extract more wort with less fuss.

Everyday Relatable: No more soggy grain beds or random husks blocking your spigot.

SKE Equipment Edge: Our 304-grade false bottom boosts runoff by 15% compared to generic screens.

3. Counterflow Wort Chiller

Rapid chilling preserves delicate hop aromas and slashes infection risk. Counterflow chillers drop wort from boiling to pitching temperature in minutes.

| Metric | Immersion Chiller | Counterflow Chiller |

|---|---|---|

| Chill Time | 20–30 minutes | 3–5 minutes |

| Wort Aeration Risk | High (stirring) | Low (sealed loop) |

| Hop Aroma Retention | Moderate | Excellent |

| Convenience | Moderate | Plug-and-play |

BCB London Tip: Pre-chill your glycol loop with ice water for sub-40°F chill times.

4. Programmable Fermentation Chamber

Yeast performance thrives on stable temperatures. A dual-zone chamber lets you mimic lager schedules or protect delicate ale profiles from heat spikes.

Home Story: That disappointing batch you lost to a summer heatwave? Never again.

SKE Equipment Feature: Built-in logging and remote alerts keep you informed—no matter where you are.

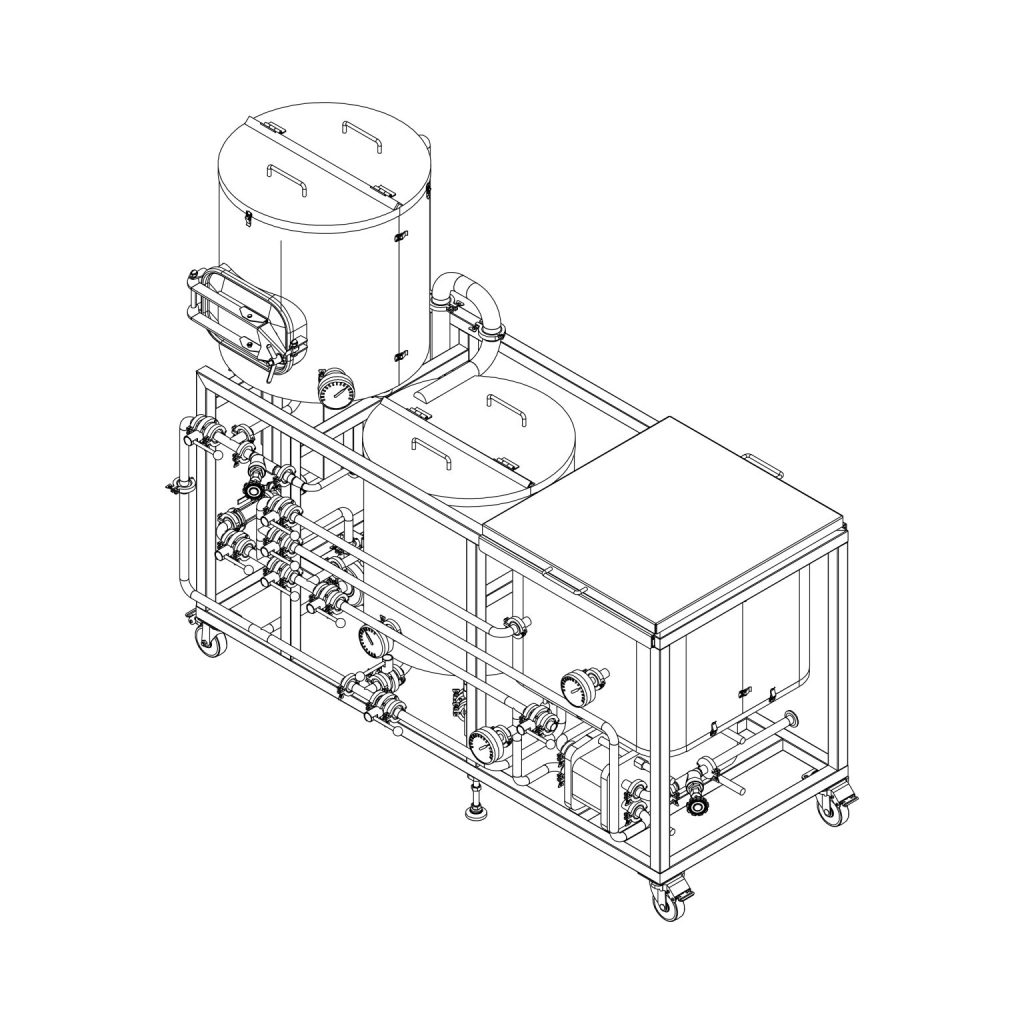

5. Automated CIP (Clean-In-Place) System

Cleaning is the least glamorous part of brewing, but also the most critical. Automated CIP system

loops guarantee thorough sanitation without back-breaking labor.

| Stage | Manual Cleaning | Automated CIP |

|---|---|---|

| Setup Time | 10–15 minutes | 2 minutes |

| Labor Intensity | High | Low |

| Consistency | Variable | Guaranteed |

| Down-Time | 30–60 minutes | 10–15 minutes |

Relatable moment: Skip the scrubbing—grab a cold one while your equipment self-cleans.

6. Precision Pump with Variable Frequency Drive

A gentle, programmable pump avoids oxygen pickup and yeast stress. Adjustable flow lets you fine-tune recirculation and transfers.

Everyday Benefit: No more wort splashing while juggling hoses—just smooth, quiet operation.

SKE Equipment Bonus: Silent operation and ultra-low pulsation keep your brew day calm.

7. Automated Bottle and Keg Filler

Packaging is your gateway to sharing. An automated filler minimizes oxidation and ensures each bottle or keg seals perfectly.

Emotional Pull: Picture serving pints at your next gathering—crisp, clear, and flawlessly poured.

BCB London Insight: Sanitary quick-disconnects let you switch between runs in seconds.

Customer FAQs

Q1: What size mash tun should a beginner choose?

A1: A 10–15 L mash tun suits 5–10 L batches perfectly. If you plan to grow, SKE Equipment’s 20 L model offers extra headspace without overwhelming your space.

Q2: Is a dedicated fermentation chamber necessary?

A2: For lagers or yeast-sensitive ales, yes. Consistent temperatures yield cleaner, more predictable profiles.

Q3: How often should I run CIP on a home setup?

A3: After every batch. A quick automated cycle under 10 minutes prevents off-flavors and extends your beer’s shelf life.

Q4: Are high-end home brewing tools worth the investment?

A4: Absolutely. Faster cycles, reliable sanitation, and up to 20% energy savings translate into better beer—and more free time to enjoy it.

Conclusion & Next Steps

Upgrading your home brewing equipment with SKE Equipment’s precision systems and BCB London–inspired protocols isn’t just buying gear—it’s investing in your craft and community. From that very first mash to the last perfectly poured pint, you’ll taste—and feel—the difference.

🎯 Ready to revolutionize your brew days? Visit SKE Equipment for custom packages, or sign up for our free BCB London masterclass on advanced brewing techniques.