Have you ever paused over a glass of amber whiskey and marveled at the journey that grain, water, and yeast took to become that silky pour? At the heart of that transformation lie specialized distillery stills, each piece of distillery equipment playing a critical role in refining flavors and capturing aromas. From the gleaming coils of a classic copper distiller to the compact precision of a home distilling kit whiskey, the right setup can mean the difference between a harsh burn and a velvety masterpiece. In this article, we peel back the curtain on nine insider secrets from SKE—secrets that can elevate every batch, whether you’re running a craft distillery or experimenting at home.

Table of Contents

1. Why Distillery Stills Define Your Spirit’s Character

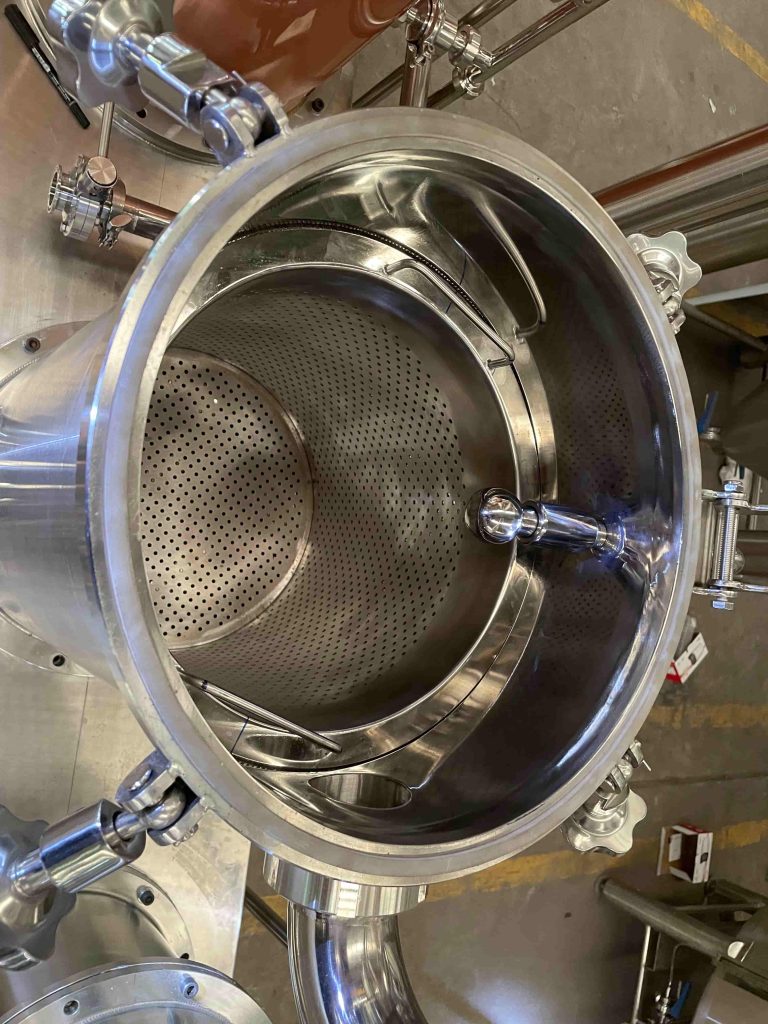

A still is more than a metal vessel—it’s where raw mash transforms into refined spirit. Distillery stills use carefully crafted geometry and premium materials to shape flavor, texture, and aroma. Small tweaks in neck length or coil spacing influence reflux and purity, directly affecting your final product. By choosing SKE’s precision-engineered stills, you tap into centuries of distilling wisdom fused with modern innovation.

2. Essential Distillery Equipment Components

Successful distillation relies on key components working in harmony:

| Component | Function | SKE Advantage |

|---|---|---|

| Pot Boiler | Heats mash to create alcohol vapor | Insulated jacket minimizes energy loss |

| Reflux Column | Refines vapor to boost purity | Modular plates allow adjustable reflux ratios |

| Copper Distiller Head | Removes sulfur compounds for a cleaner aroma | Handcrafted copper maximizes chemical reactions |

| Condenser | Cools vapor back into liquid | Multiple configurations for optimal cooling |

| Control Panel (PLC) | Automates temperature, flow, and cut detection | User-friendly touchscreen with recipe memory |

Together, these elements of distillery equipment give you control, consistency, and safety for every batch.

3. Copper Distiller vs. Stainless Steel: A Flavor Showdown

Copper’s magic lies in interacting with sulfur compounds, softening harsh notes and enriching mouthfeel. Yet stainless steel offers durability and ease of cleaning. SKE bridges both: stainless boilers with copper heads deliver robustness and flavor refinement, ensuring your distillate is both pure and full-bodied.

4. Building Your Perfect Home Distilling Kit Whiskey

A home distilling kit whiskey simplifies entry into the craft:

Education at Every Step: Witness yeast turn sugars into alcohol, then walk through cuts.

Safe, Small Batches: 5–20 L volumes reduce waste and risk while you perfect recipes.

Compact Setup: Fits on a sturdy bench, requiring minimal space.

SKE’s home kits include simplified PID controls, guiding you to precise temperatures and cut points—features usually reserved for commercial distillery stills.

5. Automating Your Still: PLC & PID Controls Explained

Automation isn’t just for large plants. With PLCs and PID controllers, you can:

Stabilize Temperatures within ±1 °C.

Program Sequences for mash ramps, reflux adjustments, and safe shutdowns.

Log Data to refine future batches.

SKE’s digital control packages remove guesswork, turning a labor-intensive process into a reliable, repeatable ritual.

6. Space & Safety: Setting Up Your Distillery Corner

Even home hobbyists must respect safety:

Ventilation to clear steam and fumes.

Fireproofing: Heat-resistant surfaces and drip pans.

Proper Drainage for spills.

SKE offers mobile skid systems that fit in a 2 × 2 m area, complete with integrated safety valves and quick-connect fittings, making compliance straightforward.

7. Scaling Up: From 5 L Pilot to 5 000 L Production Stills

Your distilling journey can grow organically:

| Scale | Volume Range | Key Upgrade | SKE Solution |

|---|---|---|---|

| Hobbyist | 5–20 L | Add reflux column | 10–50 L modular pilot stills |

| Micro Distillery | 200–2 000 L | Automated CIP, PLC | 200–2 000 L standard units |

| Commercial | 5 000–20 000 L | SCADA integration | Custom-engineered industrial stills |

Modularity in SKE’s distillery equipment means you reuse core components, slashing both capex and time to market.

8. Maintenance Mastery: Keeping Your Still in Peak Condition

Well-maintained distillery stills run cleaner and safer:

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Daily | Check gaskets, hoses, and connections |

| CIP Cleaning | After each run | Automated caustic/acid cycles |

| Copper Polishing | Monthly | Remove tarnish for optimal reaction |

| Sensor Calibration | Quarterly | Validate temperature and pressure accuracy |

| Pressure Testing | Annually | Hydrostatic test per local regulations |

Consistent care ensures longevity and repeatable quality in every batch.

9. Top Distiller Questions Answered by SKE Experts

Q1: How do I choose between pot stills and reflux stills?

A: Pot stills emphasize flavor retention—ideal for whiskey. Reflux stills deliver higher ABV and purity for vodka or neutral spirits. Hybrid options exist to cover both needs.

Q2: Is automation safe for home distilling?

A: Yes. SKE’s home systems feature built-in interlocks, automated shutdowns, and clear alarms, making automated distillation both accessible and safe.

Q3: How soon can I produce my first batch?

A: With proper fermentation, distillation, and cleanup, you can complete a test run within 10–14 days, depending on recipe complexity.

Ready to transform your spirit-making journey? Whether you’re weighing the trade-offs between a classic copper distiller or plotting your first home distilling kit whiskey adventure, SKE has the perfect solutions to unlock your next legendary batch.

👉 What’s your biggest distilling challenge right now? Drop a comment below or reach out to our SKE experts—let’s design your dream setup together!

Don’t just imagine liquid gold—brew it. 🚀