Introduction

Homebrewing is an art, a science, and a passion. For those seeking to elevate their craft, the copper pot still stands as a pinnacle of distillation technology. This time-honored apparatus, revered for its ability to produce spirits of exceptional purity and character, has found a new home in the hands of dedicated homebrewers. Whether you’re distilling whiskey, brandy, or essential oils, understanding the nuances of the copper pot still is essential for achieving superior results. The copper pot still, with its classic design, offers unique advantages. This blog will delve into the intricacies of copper pot still operation, maintenance, and the ways it can enhance your homebrewing experience.

The Science Behind the Copper Pot Still

At the heart of the pot still’s effectiveness lies its material: copper. Copper’s unique properties play a crucial role in the distillation process. It acts as a catalyst, removing unwanted sulfur compounds that can impart off-flavors to the final product. This purification process results in a smoother, cleaner spirit. The design of the pot still, with its bulbous pot and condensing arm, allows for precise control over the distillation process. The shape facilitates the separation of volatile compounds, enabling the distiller to isolate the desired fractions, or “cuts,” of the distillate. Understanding the science behind the copper pot still is key to mastering its use.

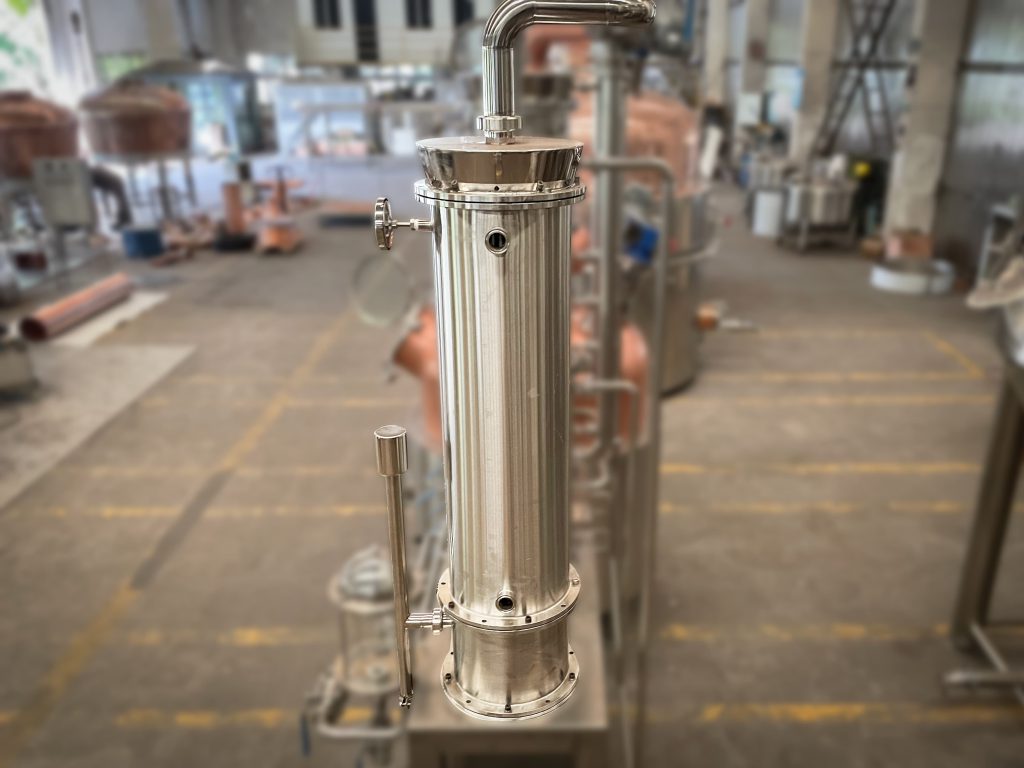

Choosing the Right Copper Pot Still for Your Needs

Selecting the appropriate copper pot still is a crucial first step. Size, design, and material quality all play a role. For homebrewers, a smaller pot still may suffice, while those with larger ambitions may opt for a more substantial setup. Consider the type of spirits you intend to produce. Whiskey, for example, may require a different design than brandy. Evaluate the craftsmanship of the copper pot still, ensuring that it is made from high-quality copper and that the seams are well-sealed. A well-constructed pot still will provide years of reliable service.

Essential Techniques for Using a Copper Pot Still

Mastering the pot still requires a blend of knowledge and skill. Proper preparation is essential. Ensure that your wash or mash is thoroughly fermented and that your pot still is clean and free of residue. During the distillation process, monitor the temperature closely and make precise cuts to separate the heads, hearts, and tails. The “hearts,” the middle fraction of the distillate, contain the desired flavors and aromas. Experiment with different distillation techniques to find what works best for your specific needs.

Maintaining Your Copper Pot Still for Longevity

Proper maintenance is essential for ensuring the longevity and optimal performance of your copper pot still. After each use, thoroughly clean the still with a mild detergent and warm water. Pay particular attention to the condenser, which can accumulate residue over time. Regularly inspect the still for any signs of damage or wear, and address any issues promptly. With proper care, your pot still will provide years of reliable service.

Safety Precautions When Using a Pot Still

Safety should always be a top priority when using a copper pot still. Distillation involves flammable liquids and high temperatures, so it’s essential to take precautions. Ensure that your workspace is well-ventilated and that you have a fire extinguisher readily available. Never leave the still unattended during operation, and always follow the manufacturer’s instructions. By adhering to safety guidelines, you can enjoy the benefits of your pot still without incident.

Copper Pot Still: A Comparative Overview

While brand comparisons are avoided, this table outlines key factors to consider when selecting a pot still, focusing on general specifications rather than specific brands:

| Feature | Consideration |

|---|---|

| Capacity | Size appropriate for batch volume. |

| Copper Quality | High-grade copper for optimal heat transfer. |

| Condenser Type | Coil or shell-and-tube, depending on efficiency needs. |

| Heating Method | Direct fire or water bath, impacting temperature control. |

| Seam Construction | Welded or riveted, affecting durability. |

| Thermometer Accuracy | Essential for precise temperature monitoring. |

| Cleaning Ease | Design for efficient post-distillation cleaning. |

| Safety Features | Pressure relief valves, etc. |

| Overall Build | Robust design. |

Troubleshooting Common Copper Pot Still Issues

Even with proper care, issues can arise when using a pot still. Leaks, blockages, and temperature fluctuations are among the most common problems. Leaks can often be repaired with soldering or sealing compounds. Blockages can be prevented by thoroughly cleaning the still after each use. Temperature fluctuations can be minimized by using a consistent heat source and monitoring the temperature closely. If you encounter any issues, consult the manufacturer’s instructions or seek advice from experienced distillers.

Conclusion

The copper pot still is a powerful tool for homebrewers seeking to elevate their craft. Its unique properties and design allow for precise control over the distillation process, resulting in spirits of exceptional quality. By understanding the science behind the pot still, choosing the right equipment, and mastering essential techniques, you can unlock a world of flavor and aroma. With proper maintenance and safety precautions, your pot still will provide years of rewarding service. Take your homebrewing to the next level today. For any questions or purchasing information, please contact us.

FAQ

Q: What is the primary benefit of using a pot still?

A: Copper removes unwanted sulfur compounds, resulting in a cleaner, smoother spirit.

Q: How often should I clean my copper pot still?

A: Clean it thoroughly after each use to prevent residue buildup.

Q: What safety precautions should I take when using a copper pot still?

A: Ensure adequate ventilation, have a fire extinguisher on hand, and never leave the still unattended.

Q: can you use a pot still for essential oils?

A: Yes, pot stills can be used for essential oil distillation.