CBCE 2025-Craft Beer China 2025

SKE EQUIPMENT WILL PARTICIPATE IN WITH INNOVATIVE EQUIPMENT

Since its establishment in 2016, Craft Beer China Conference & Exhibition (CBCE) is about to enter its tenth year.

After years of unremitting efforts and active development, CBCE has grown into the largest professional craft beer exhibition in Asia. CBCE brings together all links of the industrial chain from raw materials, brewing equipment to terminal consumption, and brings together well-known companies and brands at home and abroad to create a one-stop craft beer platform in the Asia-Pacific region.

As the tenth anniversary approaches, CBCE will continue to be committed to promoting the development of the Asian craft beer industry, bringing more new opportunities and development trends to the industry, and jointly witnessing the prosperity and growth of craft beer culture.

CBCE 2025 will cross boundaries, embrace multi-dimensional development, expand the scope of the exhibition again, introduce the craft beer kitchen system, and continue to enter the field of distilled spirits represented by whiskey and gin, as well as the hard soda and low-alcohol beverage market.

CBCE will lead exhibitors to break through traditional boundaries, grasp emerging industry trends, create diversified ecological advantages through industrial extension, and innovate and open up new development paths for craft beer and related fields.

April 15th-17th, 2025 Shanghai New International Expo Center

Welcome to CBCE 2025 SKE Booth Number: W1D20—— reliable brewing equipment innovation professional

Since its establishment in 2000, SKE has been a pioneer in the manufacture of craft beer equipment in China, with more than 20 years of industry experience and deep market insights. The company offers a wide range of product portfolios, covering craft beer and beverage equipment, turnkey projects for various breweries, cellar tanks, distillation equipment, etc., providing one-stop solutions. SKE has a professional team of project managers, technical and electrical engineers. We are committed to continuous innovation and providing customers with tailor-made, high-quality equipment. We are committed to providing excellent products and services around the world.

Features of brewer SKE equipment at CBCE 2025

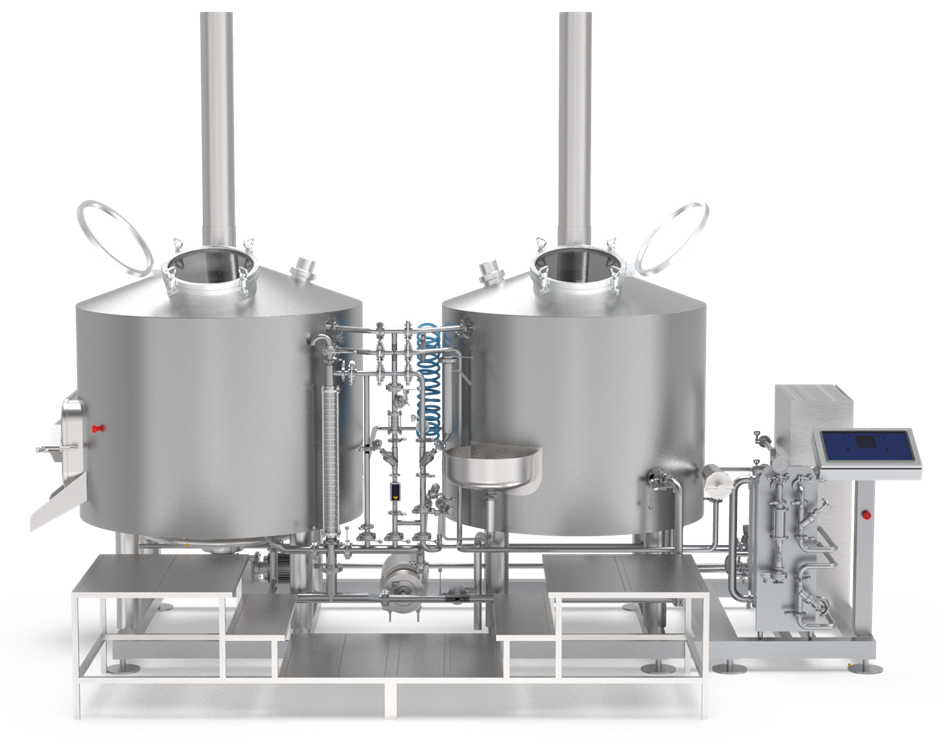

At the Craft Beer China 2025 Conference & Exhibition, SKE will be showcasing our cutting-edge nanofiltration de-alcoholizing system, along with our flash-pasteurizer and 5HL brewhouse, as well as our innovative Single vessel yeast propagation system.

CBCE 2025 Discover Innovative Brewing Solutions

SKE’s dealcoholization system is based on the principle of reverse osmosis filtration and is designed for craft breweries. Compared with distillation dealcoholization, reverse osmosis dealcoholization technology can reduce flavor loss and has lower initial investment costs.

Our standard dealcoholization equipment offers a variety of capacity options, including 3HL, 5HL, 10HL per hour, etc. We use advanced membrane technology to separate alcohol and water from beer while retaining aroma and flavor substances to the greatest extent. Under rated operating conditions, the alcohol content can be reduced to less than 0.5% with only a 10% loss of aroma and flavor.

In addition, through the diafiltration process, we are able to collect the permeate from the first filtration for making soda water or other sparkling beverages. Welcome to communicate with us face to face!

The SKE Plug & Play Brewhouse Skid is specially crafted for brewpubs, nano breweries, or as pilot brew systems. It effortlessly produces 2 batches per day, offering the following advantages:

- brewers due to its easy operation.

- Simple and straightforward installation.

- No dead legs.

- Premium piping, fittings, pumps, and valves ensure long-lasting performance.

- Designed to deliver outstanding wort quality.

- Cutting-edge instrumentation from renowned international brands guarantees a high level of automation reliability.

- Spare parts are readily available worldwide

Experience the convenience of our Compact Skid design, featuring a minimal footprint for space-saving installation. Enjoy the ease of Plug & Play setup, designed for quick and efficient integration. The Hygienic pipeline design reduces dead legs to a minimum, ensuring optimal sanitation and self-draining capabilities.

Our advanced Automated Cascade control loop ensures a smooth and gentle process, automatically managing any deviations to maintain the maximum level. The innovative PHX & loop design significantly reduces energy consumption by up to 85-90%, alleviating the load on both heating and cooling systems.

The user-friendly interface provides easy access to process control, offering a flexible range of pasteurization options to suit your specific needs.

SKE single tank yeast expansion system integrates yeast expansion and feeding functions, suitable for yeast expansion and automatic quantitative feeding of yeast products. The rotor pump is used to transport yeast to avoid high-speed shear force destroying yeast activity. Equipped with a weighing module to achieve accurate metering and control of feeding amount. The top cooling and bottom heating jacket design integrates IFM temperature sensor to accurately detect and control yeast temperature. Optional top stirring component/steam sterilization/dissolved oxygen detection and control.