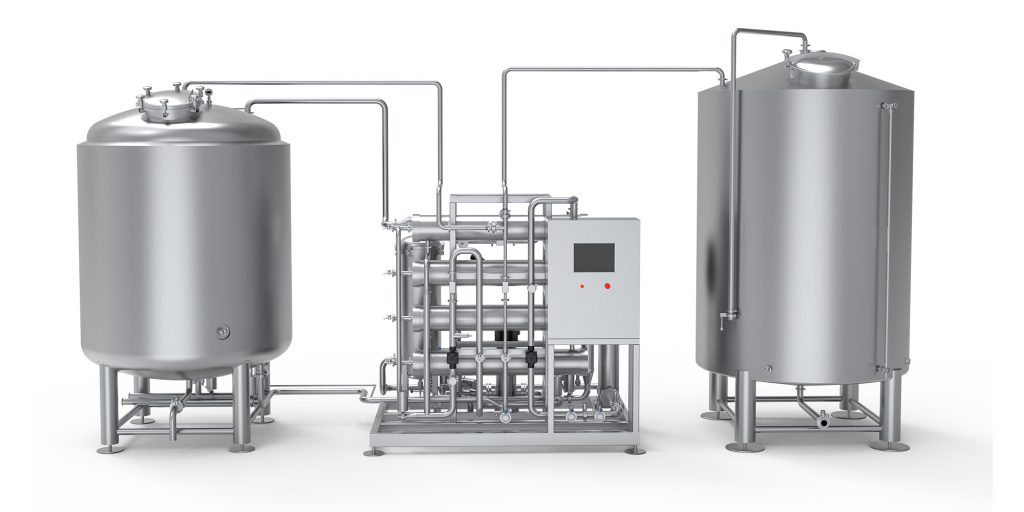

SKE Membrance De-alcoholizer

SKE de-alcoholizer is a spiral membrane filtration system dedicated to de-alcoholizing beer and other low-alcohol fermented products, offering optimal practicality and cost-effectiveness.

Skid-mounted for easy installation, it supports flexible scalability to match evolving production demands. Integrated with a CIP (Cleaning-in-Place) system and automated cleaning routines, it delivers low maintenance and replacement costs for the de-alcoholization process.

Feature

- The capacity customized by regulating paralleled membranes amounts.

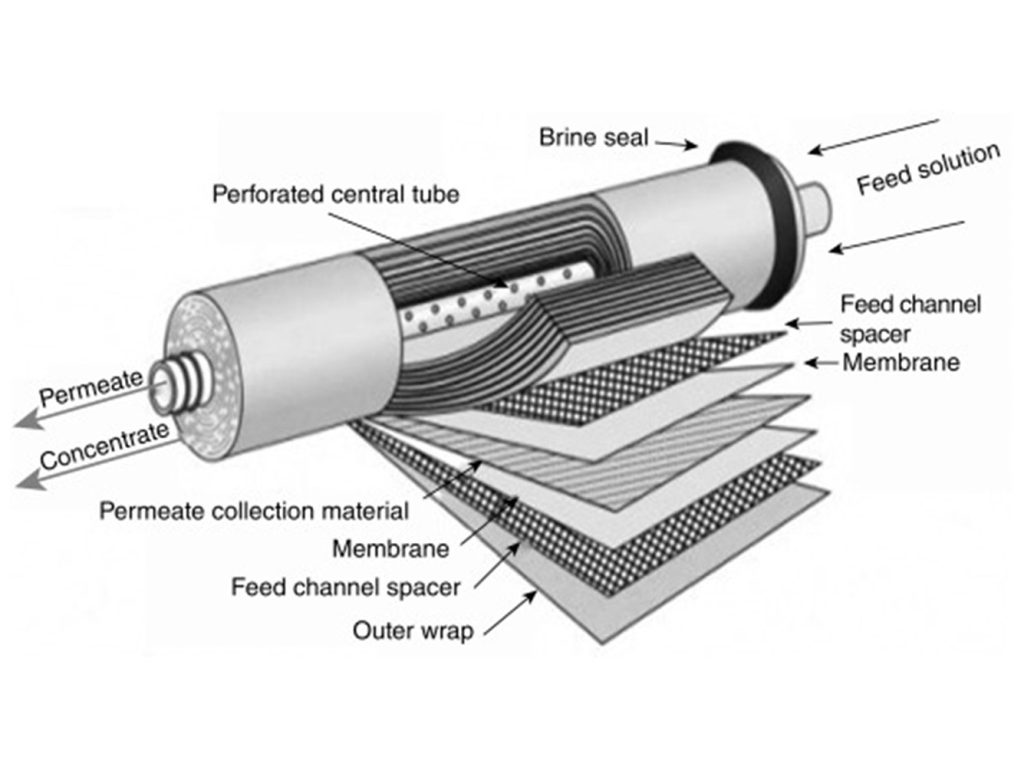

- Multiple RO membranes optional depend on ABV, capacity.

- On-line supervision: Permeate & Retentate & Dia-filtration flow detect and automatically regulate. Process working pressure supervising and interact with boost pump.

- Low aroma / flavor losses: As per rated working pressure processed that the beer aroma / flavor losses below to 15%.

- Rated beer ABV below 0.5 after processed, Variable by pressure, dia-filtration,membrane.

- Without extra energy waste, Not heating required, In-line Cooling T-HX optional.

- Dual control mode- Continuous separating / batch separating.

- Two CIP loop and one for membranes and one for rest.

- All customized for config & automation, Semi-auto Versus fully auto optional.

The most equipment can found on market for alcohol stripping are based on vacuum distilling mostly used for the massive scale with drawbacks of high investment, big footprint, energy waste, for craft size. Instead that SKE Alcol-F are a better choice for craft size with Reverse Membranes filtration with more simple config and flexibility as well as gentle & soft process.

Process

- Concentration: Boost product in system with pressure up to 10bar to push beer penetrates membranes,The light material like ethanol & water goes cross the membranes and collected into central pipe as Permeate and discharget hen whatever drain or recycle as per seltzer etc. The heavy material like flavor etc are concentrated and discharge as retentate and circulate.

- Dia-filtration: De-aerated water added and dilute concentrated retentate to help separating alcohol again. Kind of common sense like sparge process in brewing. The Dia-filtration water amount decides the final ABV in the N-A / Low-Alcohol beer.

- Dilution: Adding the de-aerated water to resume to the initial level.