Distillery equipment isn’t just a collection of shiny kettles and pipes—it’s the secret sauce behind every smooth whiskey and crisp gin you savor. But what if the difference between a mediocre batch and a world‑class spirit boils down to choosing the right copper distillery equipment and knowing where to save without sacrificing quality? Imagine uncovering the insider tips that let you build a pro‑grade home distillery setup on a shoestring budget, or learning why some stills produce neutral alcohol while others lock in complex aromas. Ready to unlock the hidden potential in your distilling journey? Let’s dive in!

What Is Distillery Equipment?

At its core, distillery equipment includes everything from mash tuns and fermenters to the still itself and downstream collection systems. The main components are:

Mash Tun: Converts grains into fermentable sugars.

Fermenter: Hosts yeast to produce wash.

Still (Pot or Column): Vaporizes and condenses alcohol.

Condenser: Cools vapor back into liquid.

Collection Vessels: Capture heads, hearts, and tails.

Leading brands like SKE Equipment engineer these modules for precision temperature control, sanitary design, and easy integration with CIP loops, ensuring every run meets rigorous standards.

Setting Up a Home Distillery Equipment Kit

For enthusiasts stepping into home distillery equipment, the basics include:

Small Mash Tun (10–20 L): Stainless steel with a false bottom.

Fermentation Vessel (20 L): Food‑grade plastic or stainless, with airlock.

Copper Still (5–10 L): Provides catalytic sulfur removal and even heating.

Condenser Coil or Liebig Condenser: Paired with an ice bath or chill water.

Thermometer & Hydrometer: Monitor wash temp and sugar levels.

Sanitation Gear: Star‑san solution, hoses, and tri‑clamp fittings.

Transitioning from mash to spirit requires patience and precision. By choosing home distillery equipment from SKE Equipment, you gain access to modular kits that scale up as your ambitions grow.

Alcohol Distillery Equipment vs. Spirit Distillery Equipment

Not all stills are created equal. Understanding the differences helps you pick the right tool:

| Feature | Alcohol Distillery Equipment | Spirit Distillery Equipment |

|---|---|---|

| Goal | Neutral, high‑proof ethanol | Flavor‑rich beverages |

| Still Type | Multi‑plate column | Pot still or hybrid column |

| ABV Range | Up to 95–96% | 40–60% |

| Flavor Retention | Minimal congeners | Preserves aromatic compounds |

| Typical Use | Fuel, pharma, home lab | Whiskey, rum, gin, brandy |

As you can see, alcohol distillery equipment focuses on purity, while spirit distillery equipment emphasizes character. Hybrid designs from SKE Equipment let you switch modes, offering the best of both worlds.

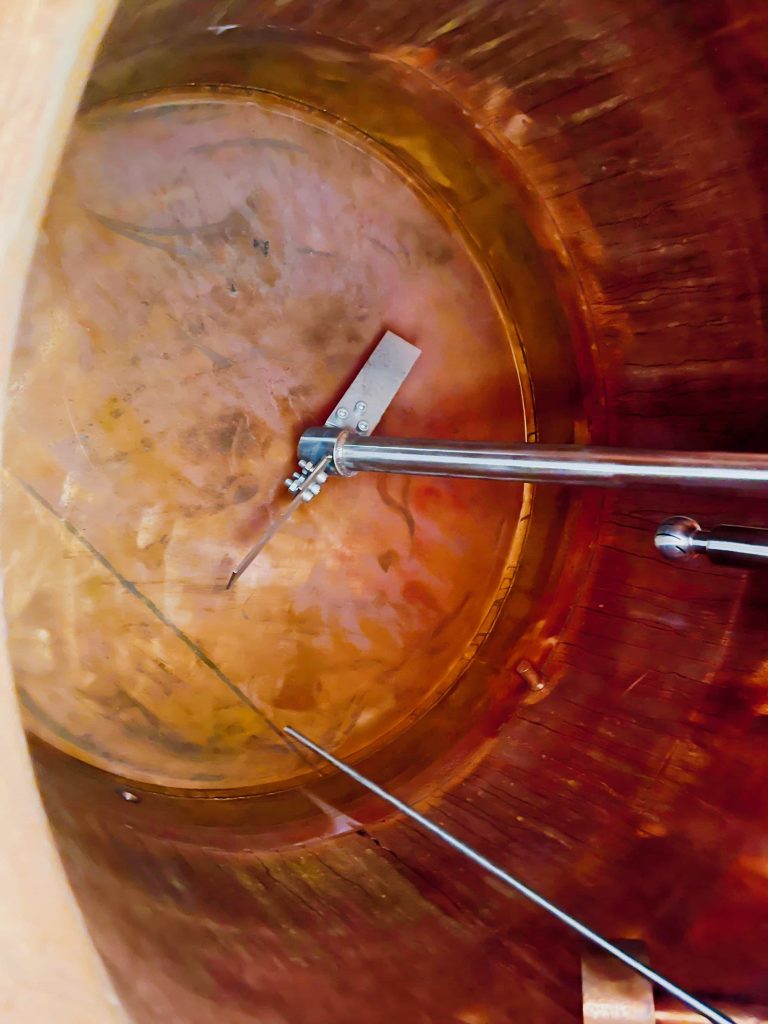

The Enduring Appeal of Copper Distillery Equipment

Copper’s role in distillation isn’t just tradition—it delivers chemical and thermal advantages:

Sulfur Binding: Copper reacts with sulfur volatiles, removing rotten‑egg aromas.

Heat Conductivity: Rapid, even heating prevents hot spots that scorch wash.

Durability: With proper care, copper stills last for decades.

For both home and commercial distilleries, investing in copper distillery equipment from SKE Equipment means cleaner spirits and fewer flavor defects.

Finding Affordable Distillery Equipment

Budget constraints shouldn’t force you to settle for subpar gear. Here’s how to source affordable distillery equipment:

Starter Kits: SKE Equipment’s beginner packages bundle mash tuns, small stills, and condensers at a discount.

Modular Expansion: Purchase core components now and add columns, extra plates, or larger tanks later.

Pre‑Owned Marketplace: Reliable used gear—inspected and refurbished—often delivers great value.

Group Buys: Collaborate with homebrew clubs to leverage bulk‑purchase discounts on distillery equipment.

A strategic approach helps you acquire quality stills and tanks without overspending, ensuring you can focus resources on recipe development and scaling.

Maintenance Practices for Long‑Lasting Performance

Routine upkeep preserves your investment and ensures safety:

| Task | Frequency | Action |

|---|---|---|

| Thorough Rinse | After each run | Flush still and condenser with hot water |

| Deep Clean | Weekly | Run a dilute acid or caustic cycle in mash tun |

| Inspect Seals & Gaskets | Monthly | Replace worn parts on still and fermenter |

| Polish & Re‑Tin | Annually | Remove patina and re‑tin copper surfaces |

| Pressure & Safety Valve Test | Every 6 months | Validate relief valves |

Following these steps—and using genuine SKE Equipment replacement parts—keeps your distillery equipment in top condition and ensures every batch is safe and delicious.

Conclusion

Whether you’re just unpacking your first home distillery equipment kit or upgrading your commercial distilling equipment lineup, understanding these fundamentals empowers you to craft better spirits. By choosing versatile copper distillery equipment, distinguishing between alcohol and spirit stills, and sourcing affordable distillery equipment wisely, you’ll streamline your path from grain to glass. Cheers to your next great batch!

Ready to turn your distilling dreams into reality? Whether you’re crafting your first small‑batch spirits or upgrading to full‑scale distillery equipment, SKE Equipment has the copper stills, modular systems, and budget‑friendly solutions you need to succeed.

👉 Get Your Custom Distillery Quote: Contact SKE Equipment

📘 Download Our Free Home Distilling Guide: Grab Your Copy

Here’s to your next masterpiece—distill boldly! 🚀🍸