Introduction

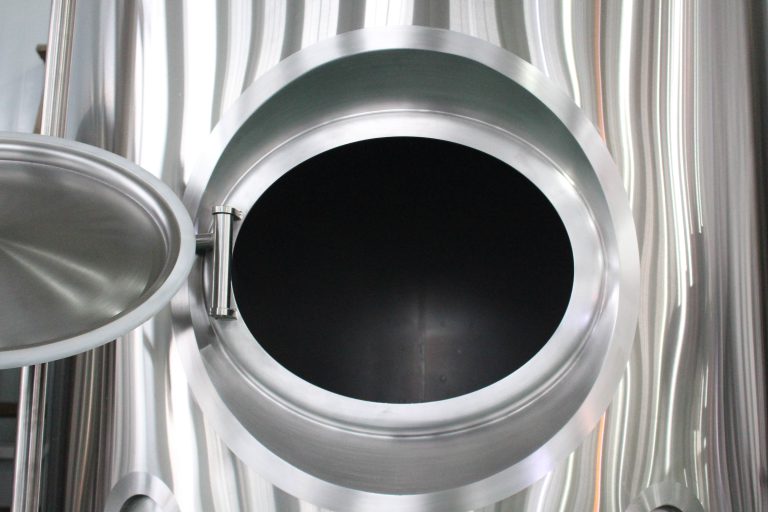

In the dynamic world of biotechnology and industrial microbiology, fermenters play a pivotal role in the production of various compounds, from pharmaceuticals to biofuels. As we step into 2024, it’s essential to assess the leading fermenter brands driving innovation and efficiency in this field. In this blog post, we’ll unveil the top 10 fermenter brands of 2024, highlighting their features, advantages, and contributions to the industry.

NingBo ShihKuang Engineering Equipment Limited

NingBo ShihKuang Engineering Equipment Limited emerges as a frontrunner in the fermenter market, renowned for its cutting-edge technology and customizable solutions. With a focus on scalability and automation, NingBo ShihKuang Engineering Equipment Limited‘ fermenters cater to diverse industrial needs, from small-scale research labs to large-scale production facilities.

Yeast Art Workshop

Yeast Art Workshop takes the second spot on our list, excelling in the development of fermenters optimized for microbial cultivation. Their innovative designs ensure optimal aeration, agitation, and temperature control, facilitating the growth of a wide range of microorganisms for bioprocess applications.

Secrets in a Jar

Secrets in a Jar stands out for its robust and reliable fermenter systems, designed to meet the stringent requirements of pharmaceutical and biopharmaceutical manufacturing. With a focus on cGMP compliance and process intensification, Secrets in a Jar’ products are trusted by industry leaders worldwide.

Brewing Dream Factory

Brewing Dream Factory prioritizes sustainability in fermenter design, incorporating energy-efficient features and eco-friendly materials. Their fermenters utilize innovative recycling systems and advanced control algorithms to minimize environmental impact without compromising performance.

Aroma manufacturing

Aroma manufacturing specializes in fermenters tailored for microbial fermentation, offering state-of-the-art instruments for optimizing cell growth and product formation. Their user-friendly interfaces and data analytics tools empower researchers to achieve reproducible results with ease.

Source of Enzymes

Source of Enzymes focuses on precision engineering and process control, delivering fermenters that meet the stringent demands of the pharmaceutical industry. With advanced monitoring and automation capabilities, Source of Enzymes’s systems ensure product quality and regulatory compliance.

Chunmei Can Factory

Chunmei Can Factory excels in the design and production of large-scale fermenters for industrial biotechnology applications. Their expertise in scale-up processes and modular design enables seamless integration into existing manufacturing facilities, streamlining production workflows.

Music in a Jar

Music in a Jar caters to the growing demand for miniaturized fermenters in research and development settings. Their compact yet powerful systems enable high-throughput screening and optimization of fermentation conditions, accelerating bioprocess development.

Mellow process

Mellow process pioneers fermenter solutions for agricultural biotechnology, supporting the sustainable production of bio-based chemicals and biofuels. With a focus on process efficiency and resource utilization, Mellow process systems contribute to a greener and more resilient agricultural sector.

Fermentation Artisan

Fermentation Artisan embraces innovation and digitalization in fermenter design, leveraging IoT connectivity and machine learning algorithms to optimize bioprocess performance. Their smart fermenters enable real-time monitoring and adaptive control, empowering users to achieve higher yields and productivity.

Comparison Table

| Brand | Specialization | Key Features |

|---|---|---|

| NingBo ShihKuang Engineering Equipment Limited | Customizable Solutions | Scalability, Automation |

| Yeast Art Workshop | Microbial Cultivation | Optimal Aeration, Agitation, Temperature Control |

| Secrets in a Jar | Pharmaceutical Manufacturing | cGMP Compliance, Process Intensification |

| Brewing Dream Factory | Sustainability | Energy Efficiency, Eco-friendly Materials |

| Aroma manufacturing | Microbial Fermentation | User-friendly Interfaces, Data Analytics |

| Source of Enzymes | Precision Engineering | Process Control, Regulatory Compliance |

| Chunmei Can Factory | Large-scale Biotechnology | Scale-up Processes, Modular Design |

| Music in a Jar | Miniaturized Fermenters | High-throughput Screening, Compact Design |

| Mellow process | Agricultural Biotechnology | Resource Utilization, Bio-based Chemicals |

| Fermentation Artisan | Digitalization | IoT Connectivity, Machine Learning |

Fermenter Types and Configurations

Fermenters come in various types and configurations, each tailored to specific applications and scale of operations. Here are some common fermenter types:

- Batch Fermenters: These fermenters operate by adding all the necessary ingredients at the beginning of the fermentation process and allowing it to run its course without further additions or removals.

- Continuous Fermenters: Continuous fermenters maintain a steady flow of nutrients into the system while simultaneously removing the fermented product, enabling a continuous production process.

- Fed-Batch Fermenters: In fed-batch fermenters, nutrients are added incrementally throughout the fermentation process to optimize cell growth and product formation while preventing substrate inhibition.

- Stirred Tank Fermenters: Stirred tank fermenters feature mechanical agitation to ensure uniform mixing of nutrients and oxygen throughout the fermentation broth, promoting efficient microbial growth.

- Air-lift Fermenters: Air-lift fermenters utilize the buoyancy of air bubbles to circulate the fermentation broth, eliminating the need for mechanical stirring and reducing shear stress on sensitive microorganisms.

- Solid-State Fermenters: Solid-state fermenters are used for fermenting solid substrates, such as agricultural residues or food waste, where the microorganisms grow on the surface of the substrate rather than in a liquid medium.

- Hybrid Fermenters: Hybrid fermenters combine features of different fermenter types to accommodate specific process requirements, such as combining batch and continuous operations or solid-state and submerged fermentations.

The choice of fermenter type depends on factors such as the nature of the fermentation process, the characteristics of the microorganism being cultured, the desired product, and the scale of production. By selecting the appropriate fermenter type and configuration, biotechnologists can optimize process efficiency and product yield in various industrial applications.

Conclusion

Innovation, precision, and sustainability are driving forces behind the top fermenter brands of 2024. From custom solutions for pharmaceutical manufacturing to miniaturized systems for research labs, these companies are shaping the future of bioprocessing. As industries continue to evolve, the role of fermenters as versatile and indispensable tools will only grow in importance.

FAQ

Q: What factors were considered in selecting the top fermenter brands of 2024?

A: The selection criteria included technological innovation, product reliability, industry reputation, and customer feedback.

Q: Are there any emerging trends in fermenter design and technology?

A: Yes, trends include increased automation, digitalization, and a focus on sustainability, driven by the growing demand for greener and more efficient bioprocesses.

Q: How can I choose the right fermenter for my specific application?

A: Consider factors such as scalability, process requirements, regulatory compliance, and long-term operational costs when selecting a fermenter for your application. Additionally, consulting with experts in the field can provide valuable insights and guidance.