Introduction

Entering the world of commercial beer brewing is an exciting venture, but it requires careful planning and significant investment, especially when it comes to selecting the right commercial beer brewing equipment. The quality and efficiency of your equipment will directly impact the quality of your beer and the success of your business. This comprehensive guide will walk you through the key considerations, helping you make informed decisions when choosing your commercial beer brewing equipment. From understanding the brewing process to evaluating different equipment options, we’ll cover everything you need to know.

Understanding the Commercial Beer Brewing Process

Before diving into the specifics of commercial beer brewing equipment, it’s essential to understand the brewing process itself. This process typically involves several key stages:

- Milling: Grains are crushed to expose the starches.

- Mashing: The milled grains are mixed with hot water to convert starches into sugars.

- Lautering: The sweet liquid, known as wort, is separated from the spent grains.

- Boiling: The wort is boiled with hops to add bitterness, flavor, and aroma.

- Whirlpooling: Solid particles are separated from the boiled wort.

- Cooling: The wort is rapidly cooled to a temperature suitable for fermentation.

- Fermentation: Yeast is added to the cooled wort to convert sugars into alcohol and carbon dioxide.

- Conditioning: The beer is allowed to mature and develop its final flavor.

- Packaging: The finished beer is packaged into kegs, bottles, or cans.

Each of these stages requires specific commercial beer brewing equipment, and the quality of this equipment will significantly impact the final product. Understanding the nuances of each stage allows for precise selection of equipment that optimizes each step. Therefore, gaining a thorough understanding of the brewing process is a prerequisite for making informed equipment purchases.

Key Components of Commercial Beer Brewing Equipment

- Brewing Vessels:

- These include the mash tun, lauter tun, brew kettle, and whirlpool. The size and material of these vessels are crucial for efficient brewing.

- The quality of the material used in the commercial beer brewing equipment will define the durability of the vessels. Investing in vessels made from high-grade stainless steel ensures longevity and resistance to corrosion, which are essential for maintaining beer quality.

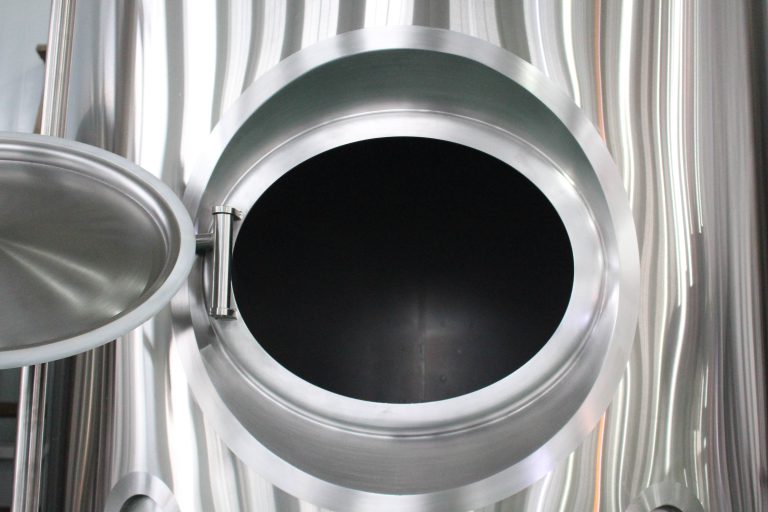

- Fermentation Tanks:

- These tanks are used for fermentation and conditioning. They come in various sizes and designs, and the choice depends on the scale of your operation. Proper temperature control within these tanks is critical for consistent fermentation results.

- Heating and Cooling Systems:

- Precise temperature control is essential for brewing. These systems include boilers, chillers, and heat exchangers. Efficient heating and cooling systems contribute to energy savings and consistent product quality.

- Filtration and Clarification Equipment:

- This equipment is used to remove impurities and clarify the beer. The choice of filtration equipment affects the clarity and overall aesthetic of the final product.

- Packaging Equipment:

- Depending on your packaging strategy, you’ll need kegging, bottling, or canning equipment. Automated packaging lines can significantly increase production speed and efficiency.

- Control Systems:

- Modern commercial beer brewing equipment often includes automated control systems for precise temperature and process control. These systems allow for remote monitoring and adjustments, ensuring consistent brewing parameters.

- Sanitation Equipment:

- Maintaining a sanitary environment is critical in brewing, requiring proper cleaning and sanitizing equipment. Effective sanitation equipment prevents contamination, which can lead to off-flavors and product spoilage.

Selecting the Right Size and Capacity of Commercial Beer Brewing Equipment

The size and capacity of your commercial beer brewing equipment should align with your production goals. Consider your projected sales volume and future expansion plans. It’s often better to invest in slightly larger equipment than you initially need to accommodate future growth. Accurately forecasting your production needs prevents costly equipment upgrades in the future. Overlooking future needs can lead to production bottlenecks and lost revenue.

Evaluating the Quality and Durability of Commercial Beer Brewing Equipment

- Material:

- Stainless steel is the industry standard for commercial beer brewing equipment due to its durability and corrosion resistance. The grade of stainless steel used impacts the equipment’s longevity and resistance to harsh brewing conditions.

- Construction:

- Look for well-constructed equipment with high-quality welds and finishes. Properly welded seams and smooth finishes prevent bacterial buildup and ensure easy cleaning.

- Manufacturer Reputation:

- Choose reputable manufacturers with a track record of producing reliable commercial beer brewing equipment. Manufacturers with a strong reputation often provide better warranties and customer support.

Understanding the Importance of Sanitation in Commercial Beer Brewing Equipment

Sanitation is paramount in brewing. Proper cleaning and sanitizing of your commercial beer brewing equipment will prevent contamination and ensure consistent beer quality. Invest in high-quality cleaning and sanitizing equipment and establish strict sanitation protocols. Implementing a comprehensive sanitation plan minimizes the risk of product recalls and maintains consumer trust.

Table of Commercial Beer Brewing Equipment Specifications

Here’s a table outlining typical specifications for various commercial beer brewing equipment components:

| Equipment Component | Specification | Considerations |

|---|---|---|

| Mash Tun | Capacity: 500L-5000L, Material: Stainless Steel 304 | Size based on batch size, insulated for temperature control |

| Lauter Tun | Capacity: Matches Mash Tun, Material: Stainless Steel 304, False Bottom | Proper grain separation, efficient wort collection |

| Brew Kettle | Capacity: Matches Mash Tun, Material: Stainless Steel 304, Direct Fire or Steam Heated | Efficient boiling, proper hop utilization |

| Fermentation Tank | Capacity: 500L-10000L, Material: Stainless Steel 304, Conical Bottom | Temperature control, pressure rating, ease of cleaning |

| Chiller | Capacity: Matches Brew Kettle, Type: Glycol Chiller | Rapid wort cooling, temperature stability |

| Kegging Machine | Capacity: 10-60 kegs/hour, Type: Automatic or Semi-Automatic | Speed and efficiency, keg size flexibility |

Conclusion

Choosing the right commercial beer brewing equipment is a crucial step in building a successful brewery. By understanding the brewing process, evaluating different equipment options, and prioritizing quality and sanitation, you can make informed decisions that will set your brewery up for success.

Are you ready to elevate your brewing operation with top-tier commercial beer brewing equipment? Don’t settle for less. Invest in the finest brewing systems that guarantee exceptional beer quality and seamless production. Contact our expert team today for personalized consultations and explore our wide range of premium commercial beer brewing equipment. Take the first step towards brewing excellence and watch your brewery thrive!

FAQ

Q: Can I finance commercial beer brewing equipment?

A: Yes, many lenders offer financing options for commercial beer brewing equipment. Securing financing allows breweries to acquire necessary equipment without a large upfront investment.

Q: What are the space requirements for commercial beer brewing equipment?

A: Space requirements depend on the size of your operation. It’s essential to plan for adequate space for brewing, fermentation, packaging, and storage. Proper layout planning optimizes workflow and ensures efficient use of space.

Q: How important is it to have automated control systems in a brewing system?

A: Very important, automated control systems will allow for the most precise control over the brewing process, which lends itself to the most consistant product possible. Automated systems reduce the potential for human error and allow for precise replication of brewing parameters.