What is the difference between propylene glycol and ethylene glycol?

The main difference between propylene glycol and ethylene is the toxicity level. Propylene glycol has very low toxicity, which is why it is also found in cosmetics and personal care products, while ethylene glycol is toxic and must be handled with care to limit human or animal exposure.

The use of propylene glycol or ethylene glycol depends on the practical application and the risk of accidental contact with food, drinking water, or human ingestion.

Just to be clear. Ethylene glycol is toxic and should not be used due to possible contact with food.

What is Propylene Glycol?

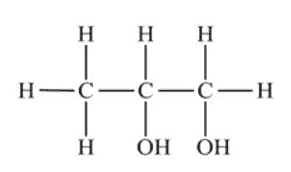

Propylene glycol is a colorless, transparent, viscous liquid with a slightly sweet taste. Its chemical structure is CH3CH[OH]CH3OH.

Propylene glycol and ethylene glycol have similar physical properties and uses.

Their chemical structures differ only by one methyl group (ethylene glycol = HOCH2CH2OH; propylene glycol = CH3CH[OH]CH2OH).Simply put, it is food-grade antifreeze.

Standards for Selecting Propylene Glycol

Manufacturers recommend USP grade propylene glycol. United States Pharmacopeia (USP) is the official standard for medicine, supplements, and health care products in the United States. Glycol displaying a USP grade assures the product is the highest quality and approved for food applications.

Beware of inexpensive, low quality, propylene glycol-based solutions available in the marketplace. Technical grade or RV rated non-toxic antifreeze, is not designed for the demands of a brewery recirculation system and could breakdown quickly, resulting in expensive equipment failure due to freezing and/or gumming up the systems heat exchangers.

If your system has galvanized (steel), black iron, or other ferrous metal components, a rust inhibitor will be needed in the solution. Many food grade propylene glycol products include inhibitors. Find out by checking the SDS (Safety Data Sheet) for the glycol you intend to use.

Percentage of propylene glycol and water in the system

The proper propylene glycol to water ratio mixture is very important in your chiller system. Too little glycol can lead to a costly freeze up. Too much glycol inhibits system efficiency.

Usually 35-40% inhibited propylene glycol is sufficient in all but the very coldest climates. Operating with a 35% glycol to 65% water Solution typically will protect from freeze up to +1 °F.

The amount of propylene glycol required for the system

First, you’ll need to determine the systems total volume.

Figure out the estimated capacity of your systems piping. (Your plumbing contractor or pipe supplier can help you, or simply take the length measurements and the inside diameter of the pipe and plug them into an online “Pipe Volume Calculator”.

Add to this, the volume held by your tank jackets (Tank manufacturer should have this number).

Finally, add the capacity of your chiller system reservoir to get you total system volume. (Chiller system tank capacity will be available from the manufacturer.)

Finally, the amount of propylene glycol needed is calculated based on the percentage of propylene glycol.

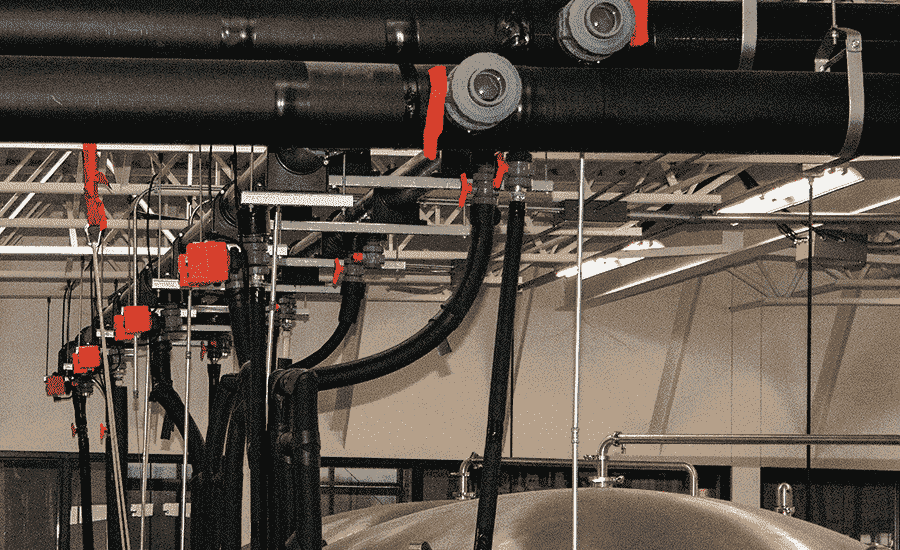

Common Types Of Glycol Piping Used In Breweries

- Glycol Piping Choices

Copper pipe is a great option for your glycol piping. Although materials and installation can be higher costed than other options, it is rigid pipe that will provide years of trouble free service.

- Pre-Insulated Schedule 80 PVC

A great economical option, Schedule 80 PVC when installed correctly performs well in breweries. We strongly discourage piping your tanks with PVC. However, up high as a rigid pre-insulated mainline, it works great. Steer clear of Schedule 40 PVC.

- ABS Plastic Piping

ABS is similar to PVC. It is available pre-insulated. Although costly, this option is engineered specifically for chilled water applications making it a preferred product for many breweries.

- Cross-Linked Polyethylene (PEX)

Typically not used as a glycol mainline, PEX is a very economical and easy to install option for tank piping.

- Nylon Braided Rubber Hose

A light duty hydraulic hose used as a transition from an ABS or Schedule 80 PVC mainline to copper tank piping. Also used as an economical tank piping solution.

To summarize, there are many glycol duct systems on the market today, and no matter which one you decide to choose, we recommend that they be fully insulated. Polyurethane foam or dense closed cell foam is preferred. Fiberglass insulation shall not be used in boiler piping. External pipes should be insulated and then clad.

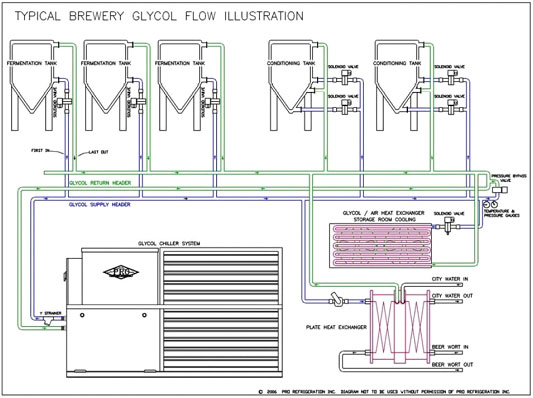

Glycol Line Layout

Here are several factors you should consider in designing and laying out your glycol system:

- Position your chiller system as close to the tanks as possible. You want as little restriction between the chiller system and tanks as possible.

- Do not use too many pipe fittings or undersized piping because that will cause increased Glycol Line pressure and possibly compromise the cooling jackets on your tanks.

- Use the “FIRST IN / LAST OUT” Piping method. The FIRST Fermenter on the SUPPLY Header, should be the LAST Tank on the RETURN Header. Please see illustration below. This balances system flow, and ensures equal flow distribution to each tank in the system.

- Install pressure (0-50 PSI) and temperature (0-50 °F) gauges in the SUPPLY header. Place them in a high visibility location. These gauges can alert you to a cooling system problem and/or a pressure problem.

- Confirm with your chiller manufacturer if the unit has an onboard bypass valve. If not, install one in the piping system. A manual ball valve at the end of the supply line that ties into the return is also recommended. This ball valve should be barely cracked open a hair, allowing a trickle of glycol through the system at all times. Another more expensive option would be to install an additional bypass valve in the piping system, set at the appropriate pressure to allow the glycol/water to barely flow through.

- It’s highly recommended that a Y-Strainer with a 20-mesh screen be included in on your glycol system return line to prevent contaminants from reaching your chiller. The Y-strainer should have a minimum size of ½” larger than your glycol mainline size.

- Each fermenter should have a dedicated chilled water solenoid valve controlled by a temperature control that senses the product temperature. When your product temperature drops to the set point temperature the solenoid valve will close shutting off the flow of glycol.