Table of Contents

From silo to mill, the journey of brewer’s grain can be fraught with dust, spillage, and back-breaking labor—unless you deploy a top-tier malt handling system. Today, we peek behind the micrometer-perfect veil of modern grain logistics to discover how SKE’s solutions keep your brewery running smoothly, safely, and efficiently.

1. Unlocking the Importance of a Malt Handling System

A robust malt handling system is more than just conveyors and elevators; it’s the backbone of any brewery’s efficiency. Properly designed grain handling:

Reduces Labor Costs: Automated elevators and conveyors eliminate manual scooping.

Minimizes Waste: Enclosed transfer prevents grain loss and reduces dust.

Enhances Safety: Less manual handling lowers the risk of back injuries and combustible dust hazards.

Boosts Consistency: Steady malt feed ensures uniform milling and mashing profiles.

Breweries adopting an advanced malt handling system often report up to 40% faster brew-in times and significant savings on raw material costs.

2. Core Components and Workflow

A modern malt handling system comprises several integrated modules to automate grain logistics:

| Component | Function | Benefit |

|---|---|---|

| Storage Silo | Bulk grain containment with moisture control | Protects malt quality |

| Bucket Elevator | Lifts grain vertically to the mill hopper | Gentle handling, minimal grain breakage |

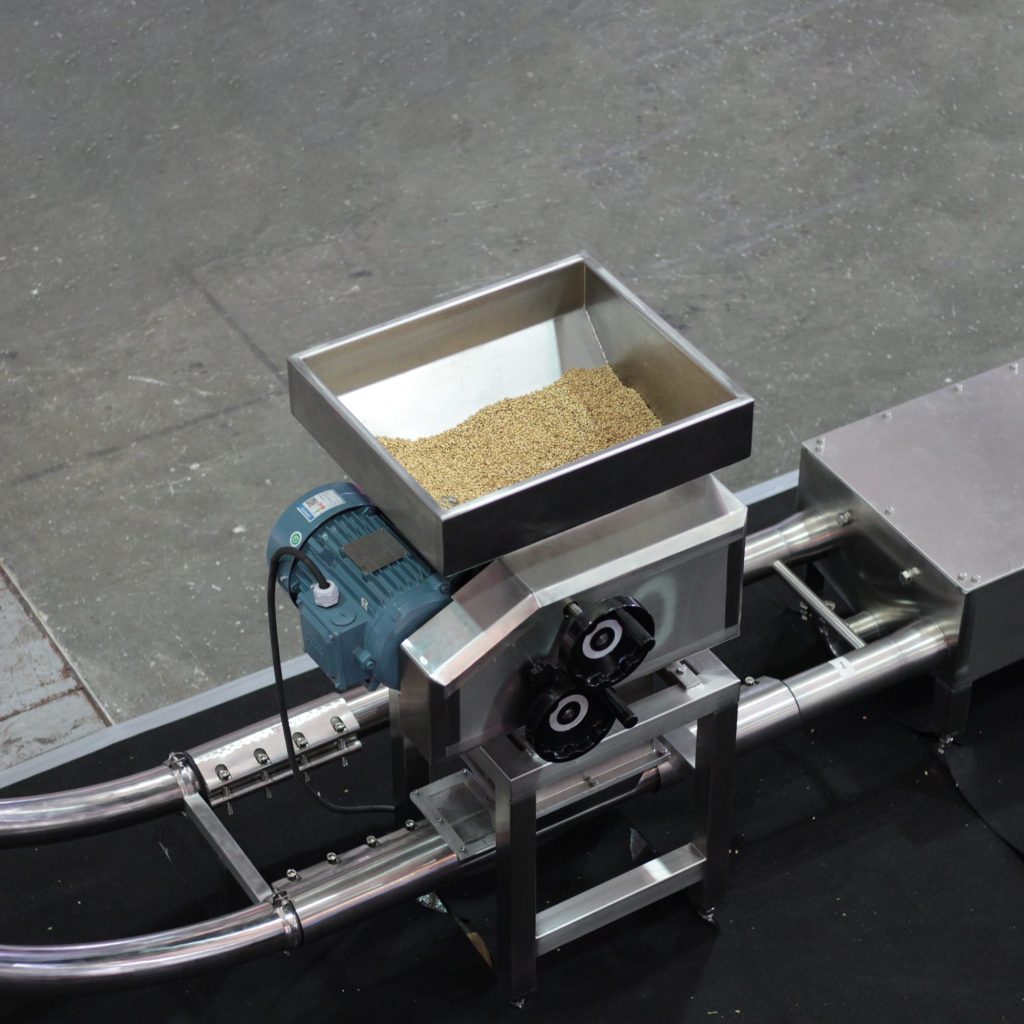

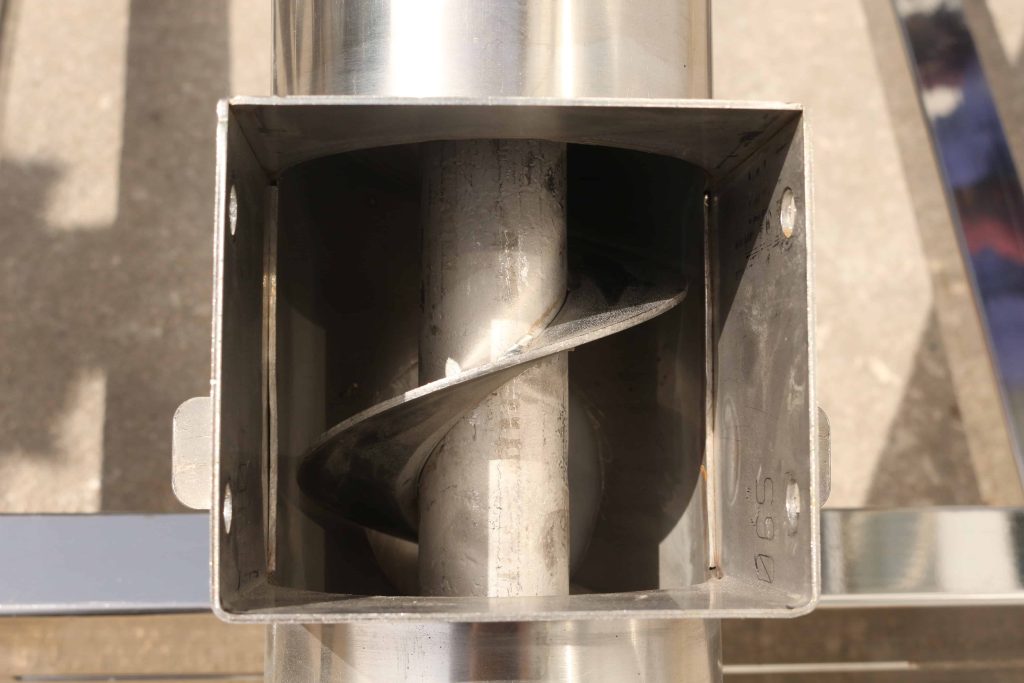

| Conveyor/Auger | Transports malt horizontally to processing areas | Adjustable flow rates |

| Magnetic Separator | Removes metal debris before grinding | Protects mill equipment |

| Vibratory Feeder | Regulates consistent malt feed into the mill | Uniform grist, efficient extraction |

| Dust Collection Unit | Captures airborne particles during transfer | Maintains air quality, reduces cleanup |

This seamless workflow ensures each kilogram of malt enters the mill in pristine condition, optimizing extract efficiency and beer quality.

3. Why Automation with SKE Matters

SKE’s malt handling system elevates automation to new heights:

Modular Scalability: Add or remove conveyors, silos, and feeders to match your brewery’s growth.

Smart Controls: PLC-driven dashboards adjust feed rates dynamically, responding to milling speed in real time.

Quick-Clean Design: Snap-in panels and CIP-compatible hoppers simplify sanitation between batches.

Robust Construction: Food-grade stainless steel and reinforced bearings ensure long service life.

With SKE’s precision-engineered hardware, breweries reduce downtime, cut maintenance costs, and maintain peak production.

4. Malt Handling System Feature Comparison

| Feature | Basic Manual Setup | SKE Automated System |

|---|---|---|

| Labor Intensity | High (manual shoveling) | Low (supervised automation) |

| Grain Loss | 5–10% | <1% |

| Line Blockages | Frequent | Rare (overflow sensors included) |

| Sanitation Time | 2–3 hours per shift | 30 minutes with quick-clean panels |

| Throughput (kg/hr) | 500 | 2,000+ |

This table highlights why investing in an SKE malt handling system pays dividends in efficiency and cost savings.

5. Expert Q&A: Solving Your Grain Logistics Woes

Q1: Can I retrofit my existing brewery with a new malt handling system?

A1: Yes. SKE’s modular conveyors and elevators adapt to varied floor plans and silo types, requiring minimal structural changes.

Q2: How do I maintain hygiene during grain transfers?

A2: Look for CIP–compatible dust hoods and quick-release panels. SKE’s malt handling system includes enclosed transfer lines and integrated dust collectors.

Q3: What safety features should I expect?

A3: Magnetic separators, overflow sensors, and spark-resistant bearings reduce mill damage and combustible dust risks.

6. Choosing the Right Malt Handling System

When evaluating options, consider:

Brewery Capacity & Growth Plans: Ensure conveyors and elevators can scale with your production.

Degree of Automation: Decide between semi-automated feeders or fully automated silos and conveyors.

Material Flow Requirements: Match equipment throughput to peak grain usage.

Service & Support: SKE offers global spare-parts distribution, rapid field service, and training.

Selecting the right malt handling system lays the foundation for consistent brewing success and easier expansion.

7. Conclusion & Next Steps

Upgrading to an automated malt handling system from SKE is more than a convenience—it’s a strategic leap toward greater efficiency, safety, and quality. By automating grain logistics, your brewery can focus on innovation and volume, rather than manual chores.

Ready to revolutionize your grain flow?Drop a comment with your biggest grain-handling challenge or contact SKE for a personalized system assessment. Let’s brew brilliance together! 🚀🍺