Introduction

When venturing into the world of craft beer, one of the fundamental elements you’ll encounter is the brewhouse. It’s the heart of every brewery, where the basic ingredients of water, malt, hops, and yeast are transformed into the delicious brews that aficionados cherish. This blog will explore the various types of brewhouses, discuss their distinctive features, and explain how they influence the beer you love.

What is a Brewhouse?

A brewhouse is the brewing section of a brewery comprising several key components such as such as mash mixer, lauter tun, kettle tank, and whirlpool tank. The configuration and sophistication of these components can vary widely, impacting everything from the brewing process to the flavor of the final product. Understanding these differences is essential for both brewers and beer lovers alike.

Types of Brewhouses

Single-Vessel Systems

Single-vessel systems, often found in smaller breweries or for home brewing, combine multiple brewing steps into one unit. These systems are not only space-saving but also more affordable, making them ideal for start-up brewers.

Two-Vessel Systems

Two-vessel systems, which typically separate the mashing and boiling processes. Such setups are common in microbreweries and offer more control over the brewing process compared to single-vessel systems.

Three-Vessel Systems

A three-vessel system adds further separation, typically including a dedicated mash tun, lauter tun, and kettle. This setup allows for simultaneous processes, reducing brewing time and increasing efficiency, which is crucial for larger operations.

Four-Vessel Systems

The four-vessel system represents the pinnacle of brewhouse complexity, adding a separate whirlpool vessel to the three-vessel setup. This arrangement maximizes efficiency and flavor extraction, ideal for high-volume commercial breweries.

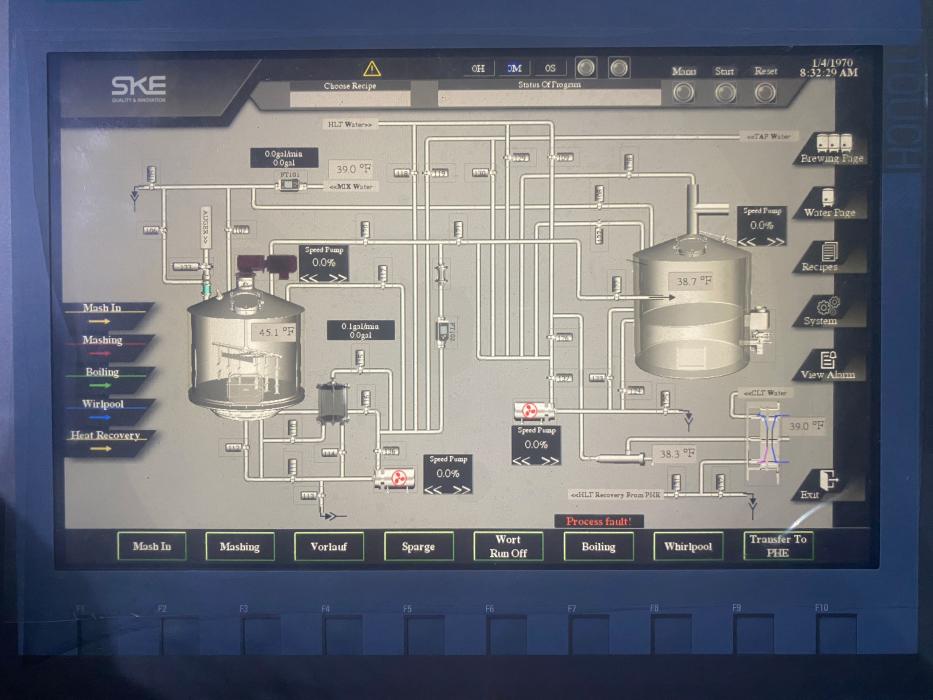

Brewhouse Technology and Innovations

As the craft brewing industry evolves, so does the technology in brewhouses. Modern advancements include automation and precision control systems that help maintain consistency and quality in brewing. This part of the blog would discuss specific technological innovations, such as computerized control panels and energy-efficient designs, that are changing the landscape of brewing.

The Role of Brewhouses in Beer Flavor

The configuration of a brewhouse is a critical factor that influences not only the efficiency of beer production but also the sensory characteristics of the final product such as flavor, clarity, and color. Different brewhouse setups, from simple single-vessel systems to complex multi-vessel configurations, play a pivotal role in defining these aspects. Here, we delve into the science of how these setups impact the brewing process, focusing on mash efficiency, wort clarity, and flavor extraction.

Mash Efficiency

Mash efficiency is a measure of how effectively a brewhouse converts the starches in malted grain into fermentable sugars during the mashing process. This efficiency depends largely on the type of mash tun used and the control a brewer has over the mashing temperatures and times. For instance, a two-vessel system, which separates the mashing and boiling processes, allows for more precise temperature control, which can optimize enzyme activity for sugar conversion. Higher mash efficiency means more sugars are extracted, which not only impacts the potential alcohol content but also influences the body and sweetness of the beer.

Wort Clarity

Wort clarity refers to the visual clearness of the liquid extracted during the mashing process, which is crucial for the final clarity and visual appeal of the beer. Solid particles need to be effectively removed before fermentation, as their presence can lead to haziness and unwanted flavors. Systems with a dedicated lauter tun, like in three- and four-vessel setups, allow for a more thorough filtration of the mash, separating solids from the liquid more effectively. The clearer the wort, the purer and cleaner the flavor profile of the finished beer, as it reduces the risk of off-flavors derived from grain husks or protein residues.

Flavor Extraction

Flavor extraction during brewing is significantly influenced by the configuration of the brewhouse, particularly during the boiling and hopping stages. The kettle, where boiling occurs, is integral for flavor development. Boiling not only sterilizes the wort but also enables the extraction and isomerization of alpha acids from hops, which contributes to the beer’s bitterness and stabilizes its flavor. In more complex systems, such as those with an additional whirlpool vessel, hops can be added at varying stages of the boil to enhance flavor profiles further. This method allows for the creation of layers of flavors, from deep bitterness to bright, aromatic notes depending on when hops are introduced.

Integrated Systems and Flavor Consistency

Advanced brewhouses often feature integrated systems that help maintain consistency in beer production. Automated control systems can regulate temperatures, timings, and ingredient additions with high precision across different batches. This level of control is crucial for replicating successful recipes accurately, ensuring that each batch of beer remains true to the expected flavor profile, clarity, and color.

The Impact of Material and Design

Finally, the material and design of the brewhouse also affect the flavor. Stainless steel, commonly used in brewhouses, is favored for its durability and non-reactive properties, which ensure that no external flavors are imparted to the beer. The design of the vessels, including aspects like heating methods (direct fire, steam jackets, or electric elements) and vessel shape, can influence how evenly heat is distributed during mashing and boiling, affecting both efficiency and flavor extraction.

Brewhouse Table: Comparing Systems

| Brewhouse Type | Capacity | Ideal For | Pros | Cons |

|---|---|---|---|---|

| Single-Vessel | Small | Home brewing, small setups | Cost-effective, minimal space required | Limited control, lower efficiency |

| Two-Vessel | Medium | Microbreweries | Better process control than single | Higher cost, more space required |

| Three-Vessel | Large | Larger breweries | High efficiency, good process control | Higher initial investment, more space |

| Four-Vessel | Very Large | Commercial breweries | Maximum efficiency and control | High cost, requires significant space |

Maintenance and Cleaning of Brewhouses

Maintaining and cleaning a brewhouse is not just a routine chore; it is a critical component of the brewing process that directly affects the quality, flavor, and safety of the beer. This section explores the standard cleaning processes, including the use of specific cleaning agents like caustic soda, and underscores the importance of regular maintenance to prevent contamination, preserve equipment, and ensure consistent beer quality.

Importance of Cleanliness in Brewing

Cleanliness in the brewhouse is paramount. Any residues from previous batches, such as hops, grain particles, or yeast, can become sources of microbial contamination that may spoil subsequent batches of beer. Such contamination not only affects the beer’s flavor and aroma but can also lead to health concerns. Regular and thorough cleaning ensures that each batch starts in a completely sanitized environment, critical for maintaining high-quality beer production.

Cleaning Agents and Their Uses

- Caustic Soda (Sodium Hydroxide): This is one of the most commonly used chemicals in brewery cleaning. Caustic soda is highly effective at removing organic residues like proteins and fats because of its strong alkaline nature. It’s typically used in a hot cleaning cycle to clean the interior surfaces of brew kettles, pipes, and fermenters.

- Acid Cleaners: These are used following a caustic clean to neutralize any remaining alkaline residues and to remove mineral deposits that caustic soda cannot clean, such as beer stone (calcium oxalate deposits). Phosphoric and nitric acids are the most common acid cleaners in breweries.

- Sanitizers: After cleaning with caustic soda and acids, surfaces must be sanitized. Common sanitizers include peracetic acid and iodophor. These chemicals are effective against bacteria and yeast, ensuring that the equipment is microbiologically stable before the next use.

- Non-Caustic Cleaners: Used for less intensive cleaning needs, non-caustic cleaners are typically enzyme-based or oxygen-based cleaners that can effectively remove organic materials without the harshness of caustic soda, making them suitable for use on more sensitive equipment.

Cleaning Procedures

A typical cleaning cycle in a brewhouse might include several steps:

- Rinse: Initial rinsing with water to remove loose particles.

- Caustic Wash: Circulating hot caustic soda solution through the system to break down organic residues.

- Intermediate Rinse: Removing any residual caustic cleaner with hot water to prepare for acid washing.

- Acid Wash: Using acid cleaners to remove inorganic deposits and neutralize any leftover alkalinity.

- Final Rinse: A thorough rinsing with water to clear out all chemicals.

- Sanitization: Applying a sanitizer to all surfaces that come into contact with the beer.

Regular Maintenance and Inspection

Besides regular cleaning, ongoing maintenance and periodic inspections of the brewhouse equipment are essential to prevent mechanical failures and ensure operational efficiency. This includes checking seals and valves for leaks, inspecting heating elements for scale buildup, and ensuring that sensors and control systems are functioning correctly. Preventative maintenance not only extends the lifespan of the equipment but also minimizes the risk of unexpected breakdowns that can interrupt production and lead to costly repairs.

Training and Documentation

Effective maintenance and cleaning also rely on proper training and documentation. Brewery staff should be thoroughly trained in both the proper use of cleaning chemicals and the specific cleaning protocols for their particular equipment. Documentation of cleaning schedules, procedures followed, and maintenance checks can help in troubleshooting problems and proving adherence to food safety standards, particularly during inspections by regulatory authorities.

Conclusion

Brewhouses are as varied as the beers they produce. Choosing the right type of brewhouse is crucial for achieving the desired quality and efficiency in beer production. Whether you are a home brewer or looking to start a commercial brewery, understanding the nuances of different brewhouse setups can guide you to the best choices for your brewing ambitions.

Understanding the brewhouse is just the beginning of mastering the craft of beer making. Each type of brewhouse brings its own set of challenges and benefits, shaping the very character of the beers produced. As the craft beer industry continues to evolve, so too will the technologies and techniques used in brewhouses around the world, continuously enhancing the beer drinking experience.

By diving into the types and technologies of brewhouses, we gain a greater appreciation for the beverage and the complex processes involved in its creation. Cheers to a deeper understanding and better beer!

FAQ

What is the best type of brewhouse for a small brewery?

The best type for a small brewery is often a two-vessel system, which provides a good balance between cost, space, and control over the brewing process.

How much does it cost to install a brewhouse?

Costs can range from a few thousand dollars for a basic home brewing setup to several hundred thousand for a state-of-the-art commercial installation.

Can brewhouse setup impact beer clarity?

Yes, the separation and specificity of vessels in more elaborate systems can greatly improve wort clarity, which in turn impacts the clarity of the finished beer.

What are the energy considerations with different brewhouses?

Energy efficiency varies significantly between systems, with larger, more modern setups often including features designed to minimize energy use.