Introduction

Brewing beer is an age-old craft that combines science, art, and a bit of magic. One of the most critical phases in this process is fermentation, where yeast converts sugars into alcohol and carbon dioxide. The vessel in which this process occurs—commonly referred to as beer fermenting vessels—can significantly influence the outcome of the beer. From the flavors and aromas to the clarity and carbonation, the choice of fermenting vessel is vital for both amateur and professional brewers. In this blog, we will explore various types of beer fermenting vessels, their advantages, disadvantages, and how they can impact the brewing process.

What Are Beer Fermenting Vessels?

Beer fermenting vessels are containers designed specifically for the fermentation of beer. They can vary in size, shape, and material, which ultimately affects the fermentation environment and the beer’s final characteristics. Understanding these differences is essential for brewers who wish to control and enhance the fermentation process, ensuring a high-quality final product.

The Role of Fermentation in Brewing

Fermentation is a critical step in brewing, transforming sweet wort into beer. During fermentation, yeast not only produces alcohol but also contributes to the beer’s flavor profile. Various factors, including temperature, oxygen levels, and the type of fermenting vessel, can influence how the yeast behaves during fermentation.

Types of Beer Fermenting Vessels

Choosing the right beer fermenting vessels can be overwhelming given the variety available. Below are some of the most common types of fermenting vessels used by brewers.

Glass Carboys

Glass carboys have been a staple in homebrewing for decades. Their clear design allows brewers to observe fermentation activity closely, which can be especially satisfying.

Advantages:

- Non-Reactive Material: Glass does not interact with the beer, ensuring that no off-flavors are imparted.

- Visibility: The transparent nature of glass carboys allows brewers to monitor fermentation, helping to gauge the process effectively.

- Easy Cleaning: Glass can be thoroughly sanitized, reducing the risk of contamination.

Disadvantages:

- Fragility: Glass is prone to breakage, which can be a significant concern during handling.

- Limited Capacity: Most carboys are limited to smaller batches, typically between 5 to 6 gallons.

Plastic Fermenters

Plastic fermenters have gained popularity due to their lightweight and durable nature. They come in various sizes and shapes, often equipped with features that facilitate the brewing process.

Advantages:

- Durability: Plastic is shatterproof, making it less prone to accidents compared to glass.

- Cost-Effective: Generally, plastic fermenters are more affordable than their glass and stainless steel counterparts, making them accessible for beginners.

- Convenience: Many plastic fermenters come with spigots, allowing for easy bottling without transferring the beer.

Disadvantages:

- Scratching Risks: Plastic can scratch easily, and scratches can harbor bacteria if not cleaned properly.

- Limited Visibility: Most plastic fermenters are opaque, making it difficult to visually monitor fermentation progress.

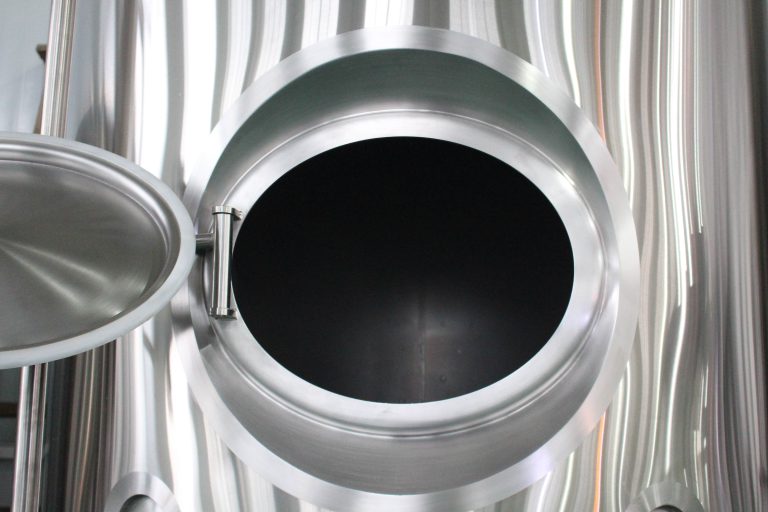

Stainless Steel Fermenters

Stainless steel fermenters are increasingly favored in both commercial and homebrewing settings. Their robust design and hygienic properties make them a long-term investment for serious brewers.

Advantages:

- Durability: Stainless steel is incredibly durable and resistant to rust and corrosion.

- Non-Reactive: Like glass, stainless steel does not react with beer, ensuring a clean taste.

- Temperature Control: Many stainless steel fermenters come with insulation options that help maintain optimal fermentation temperatures.

Disadvantages:

- Cost: The initial investment can be high compared to glass or plastic options.

- Weight: Stainless steel fermenters can be heavy, making them cumbersome to move, especially when full.

Conical Fermenters

Conical fermenters are a type of stainless steel vessel designed for both fermentation and yeast collection. They have a conical shape that allows sediment to settle at the bottom, making it easier to remove yeast after fermentation.

Advantages:

- Yeast Harvesting: The design allows for easy collection and reuse of yeast, which can save costs for future batches.

- Reduced Oxidation Risks: The conical shape minimizes the need for transferring beer, reducing exposure to oxygen.

- Cold Crashing: This process, where the temperature is lowered post-fermentation, helps clear the beer by forcing suspended particles to settle.

Disadvantages:

- Higher Initial Investment: These fermenters are typically more expensive than traditional fermenters.

- Space Requirements: Their design often requires more vertical space, which may not be feasible in all brewing environments.

Open Fermenters

Open fermenters are traditional vessels that allow natural exposure to wild yeast and bacteria. While less common today, they are still used in some brewing styles, particularly Belgian beers.

Advantages:

- Complex Flavors: Open fermentation can introduce unique flavors and aromas, contributing to a more complex beer.

- Historical Significance: This method has a rich brewing heritage, often employed by artisanal brewers.

Disadvantages:

- Contamination Risk: The exposure to the open air increases the risk of unwanted microorganisms affecting the beer.

- Requires Skill: Open fermentation demands more experience and monitoring to ensure quality.

Comparing Beer Fermenting Vessels

To better understand the various beer fermenting vessels, here’s a comprehensive comparison table summarizing their key features:

| Type | Material | Capacity | Visibility | Ease of Cleaning | Cost |

|---|---|---|---|---|---|

| Glass Carboys | Glass | 5-6 gallons | High | Moderate | Low |

| Plastic Fermenters | Plastic | Varies | Moderate | Easy | Low |

| Stainless Steel | Stainless Steel | Varies | Low | Easy | High |

| Conical Fermenters | Stainless Steel | Varies | Low | Easy | High |

| Open Fermenters | Wood/Other | Varies | Low | Moderate | Variable |

Factors to Consider When Choosing Beer Fermenting Vessels

When deciding which beer fermenting vessels to use, several factors should be taken into account:

Batch Size

The size of the batch you plan to brew will significantly influence your choice of fermenting vessel. Smaller batches may suit glass carboys, while larger batches will require more substantial vessels like stainless steel fermenters.

Type of Beer

Different beer styles may benefit from specific fermenting vessels. For example, open fermenters might enhance the unique flavors of certain Belgian beers, while conical fermenters are ideal for lagers that benefit from yeast harvesting.

Budget

Your budget will also play a crucial role in your decision. While glass and plastic fermenters are generally more affordable, investing in stainless steel can enhance your brewing experience and improve the final product quality.

Best Practices for Using Beer Fermenting Vessels

Regardless of the type of fermenting vessel you choose, adhering to best practices will help ensure a successful fermentation process:

- Sanitize Everything: Proper sanitation is vital to prevent contamination. Clean all equipment thoroughly before use.

- Monitor Temperature: Yeast thrives within specific temperature ranges. Use temperature control methods as needed.

- Seal Properly: Ensure that your fermenting vessel is sealed to prevent unwanted oxygen and contaminants from entering.

- Patience is Key: Allow adequate time for fermentation to occur, as rushing the process can lead to off-flavors or incomplete fermentation.

Conclusion

Understanding the various types of beer fermenting vessels is crucial for any brewer seeking to refine their craft. Each type of vessel offers unique advantages and disadvantages that can significantly influence the fermentation process and the final characteristics of the beer. By carefully considering factors such as batch size, beer style, and budget, brewers can make informed choices about their fermenting vessels, leading to better quality beer and an overall improved brewing experience.

FAQ

What is the best material for a beer fermenting vessels?

The best material depends on your brewing goals. Glass and stainless steel are popular for their inert properties, while plastic is great for beginners due to its affordability.

How do I clean my fermenting vessel?

Cleaning typically involves rinsing with hot water, using a brewery-approved cleaner, and sanitizing before use to prevent contamination.

Can I ferment beer in a plastic bucket?

Yes, plastic buckets are commonly used for fermentation, especially by homebrewers. Just ensure they are food-grade and properly sanitized.

What is the advantage of using a conical fermenter?

Conical fermenters allow for easy yeast harvesting and sediment removal, which can lead to clearer beer and less oxidation.

How does the shape of the fermenting vessel affect fermentation?

The shape can influence how yeast and sediment settle, affecting clarity and flavor. Conical shapes are particularly effective at collecting yeast and sediment.