Introduction

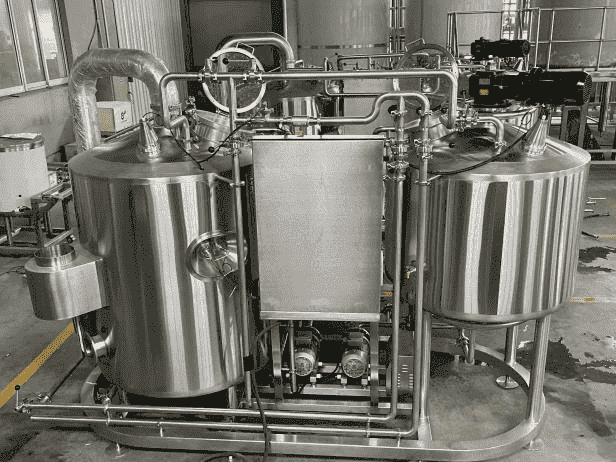

Essentially this was a long debated questions of what’s the best heating source from the brewery but unfortunately without a certain answer. In most scenes that for different working conditions or circumstance the answer are keep changing and therefore the most-key is how to determiner or how to evaluate which is your best heating source. Which we have outlined below for your convenience.

Type of heat source

Steam Heating

Pros:

- Literally it’s the ideal heating source for all kind of breweries but in fact was mostly used for the commercial scale.

- Especially when you run the boiler with gas heating, it’s the good heating efficiency and love energy cost.

- Reliable & safe & flexible process controls, fundamental but also be the critical aspect in brewing industrial.

- Each brewer’ll got what’s the best feels of steam heating whilst they use other heating sourced kits.

Cons:

- Highest cost option for the either brewing equipment & energy facility, Steam controls is the most complicated on in among heating sources and required a series of control & safe components. As same as the steam generator, the local authority has the requirements and procedures of certification & registration,annual inspection etc.

- Obviously which also won’t be a cost-effective way for small / brewpubs kit.

- In some regions like CA, TX, EU, there’re carrying out the specific emissions standards and adding the extra cost in further. For others states like NY, WI, PA etc the working pressure of the steam can be only below 1bar and in some sense this decline the heating conduction efficiency and worsen the pros of steam heating option.

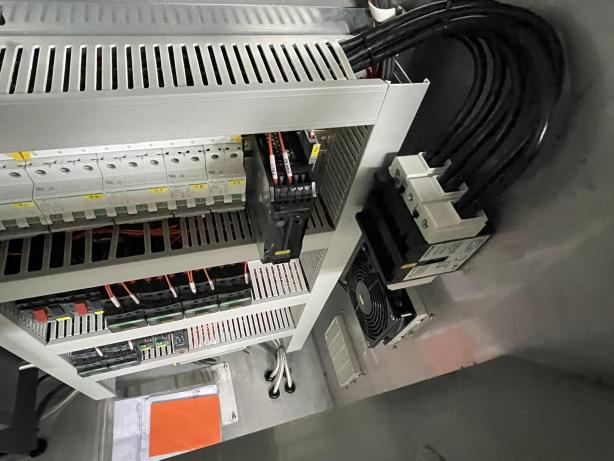

Elec Heating

Pros:

- Predictable cost & minimum investment charge.

- Highest energy utilising as there’re just 1 stage power convert: Electricity to heat

- Minimum equipment overhaul & maintainance cost.

- Easiest & direct control principle.

Cons:

- Probably be the highest energy cost for longer prospect even higher than steam generator investment.

- Regular maintainance or replacements of the heating elements.

- Required the strong power supply on your facility to be sufficient to run the high-power heating elements.

Direct Fire Heating

Pros:

- Can be the lowest upfront cost.

- The preferred caramelization can be got by gas heating system.

- Considerable option for pub / commercial system where don’t have strong power for elec heating and save more investment than steam apparatus.

Cons:

- Lowest energy utlizing and the heating convert efficiency was just 25-50%.

- Special requirements like fire-fighting, ventilation etc for the architecture for abide to the burner & local exhaust standards.

- Extra cost for the the burners according to the local emission standards like CA / TX.

Hot Oil Heating

Compared with the traditional steam heating brewhouse, the creative new-tech thermal oil heating avoids steam condensation and provides more possibility in reducing energy consumption in the brewing process, while achieving the same or better output.

But in real working circumstance the unmanageable temp control for the brewing would also be a pain for the brewers as the oil’s latent heat is considerable high than the steam, water etc, Means the oil is still release the heating even if the temp hit to the desired.

Also considering the toxic oil medium is also be a issues for this innovation spreading much more in the commercial scale breweries。

conclusion

If still without a certain solutions for your setup and shot us at info@skeequipment.com for discussion and we’d happy to work out the individual options with specs for your convenience.