When it comes to brewing, the cleanliness of your kegs is just as crucial as the quality of the beer itself. A reliable beer keg washing machine is essential for ensuring that each batch of beer maintains its intended flavor and is free from contaminants. This comprehensive guide will explore the essential factors to consider when selecting a beer keg washing machine for your brewery, ensuring you make a well-informed decision that enhances your brewing process.

Introduction

In the bustling world of craft breweries, the efficiency and effectiveness of your operations can significantly impact your product’s quality and your business’s overall success. One of the key components in maintaining this quality is the beer keg washing machine. This machine not only ensures the sterility and cleanliness of your kegs but also helps in maintaining a consistent taste and quality of the beer. Understanding the features, types, and maintenance requirements of keg washers will aid in selecting the right machine for your needs.

Understanding Different Types of Keg Washers

Single-Station Keg Washers

Single-station washers are compact and cost-effective, making them ideal for smaller breweries or those just starting. They clean one keg at a time and can be a good entry-level option.

Multi-Station Keg Washers

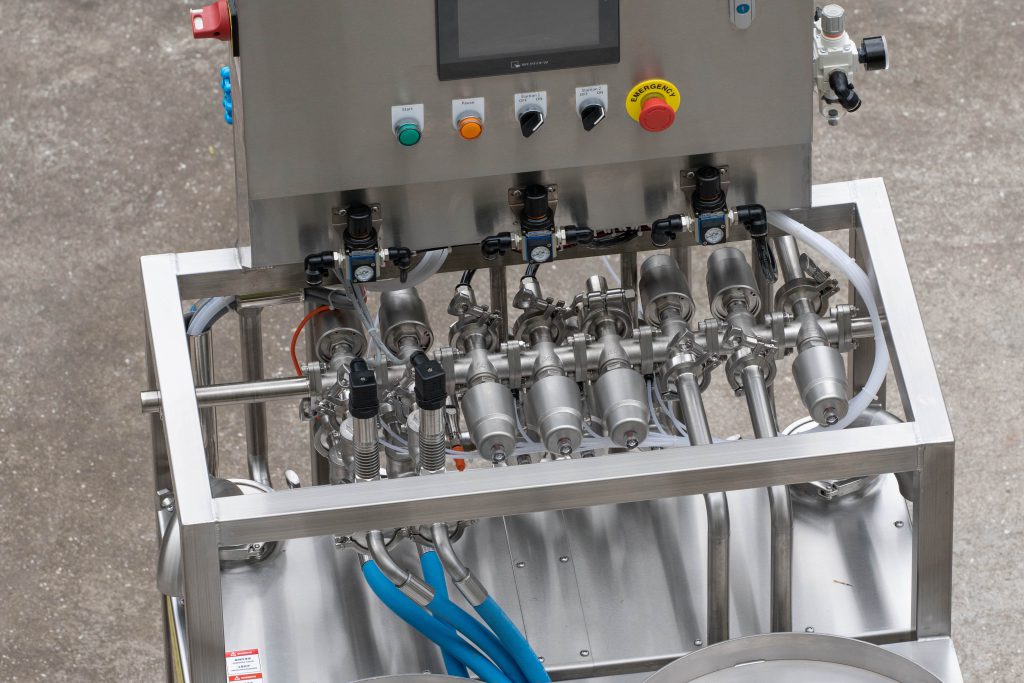

For larger operations, multi-station keg washers offer increased efficiency by cleaning several kegs simultaneously. These systems reduce washing time and are perfect for breweries with higher production demands.

Automated Keg Washing Systems

Fully automated systems offer the highest efficiency and least manual intervention. They are equipped with various settings for different cleaning needs and can handle large volumes of kegs seamlessly.

Key Features to Look For

When shopping for a beer keg washing machine, consider these essential features to ensure you choose the best option for your brewery:

- Cleaning Efficiency: How effectively does the machine remove residues and sanitize the kegs?

- Cycle Time: How long does each washing cycle take?

- Water and Chemical Usage: How much water and cleaning chemicals does the machine use per cycle?

- Durability and Construction: What materials is the machine made from? Stainless steel units offer longevity and resistance to corrosion.

- Ease of Use: Is the machine user-friendly? Can your staff operate it with minimal training?

- Maintenance Requirements: How easy is it to maintain the machine? What are the typical repair needs?

Placement and Installation Tips

Space Requirements

Ensure your chosen model fits in the designated area in your brewery. Consider both the size of the machine and any additional space needed for operation and maintenance.

Utility Connections

Check the requirements for electrical and water connections, and ensure your brewery can accommodate these needs.

Compliance and Safety

Ensure the machine meets all local regulations and safety standards to protect your staff and facility.

Maintenance and Upkeep

Regular maintenance is crucial for the longevity and effectiveness of your beer keg washing machine. Schedule routine inspections and cleanings, and train your staff on the proper upkeep procedures. Keep a log of all maintenance activities to help diagnose any future problems.

Conclusion

Choosing the right beer keg washing machine is a critical decision for any brewery. By considering the types of washers available, the key features, installation requirements, and maintenance needs, you can select a machine that fits your brewery’s size and production capacity while ensuring optimal cleaning performance. Investing in the right equipment will help you maintain the highest standards of beer quality and brewery efficiency.

FAQ

What is the average cost of a beer keg washing machine?

Prices can range from a few thousand dollars for a basic model to tens of thousands for a fully automated system, depending on the features and capacity.

How often should I maintain my beer keg washing machine?

It’s recommended to conduct routine maintenance and inspections at least every six months, but this can vary based on usage.

Can I customize a keg washer to fit my specific needs?

Many manufacturers offer customizable options for their machines, including adjustments to cycle times, water usage, and capacity.